Backwashing membrane distillation device based on dielectric wetting membrane and operation mode

A technology of dielectric wetting and operation mode is applied in the field of backwashable membrane distillation devices and operation modes, which can solve the problems of backwashing and membrane distillation system failure, and achieve simple operation, broad application prospects and low energy consumption of the device. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

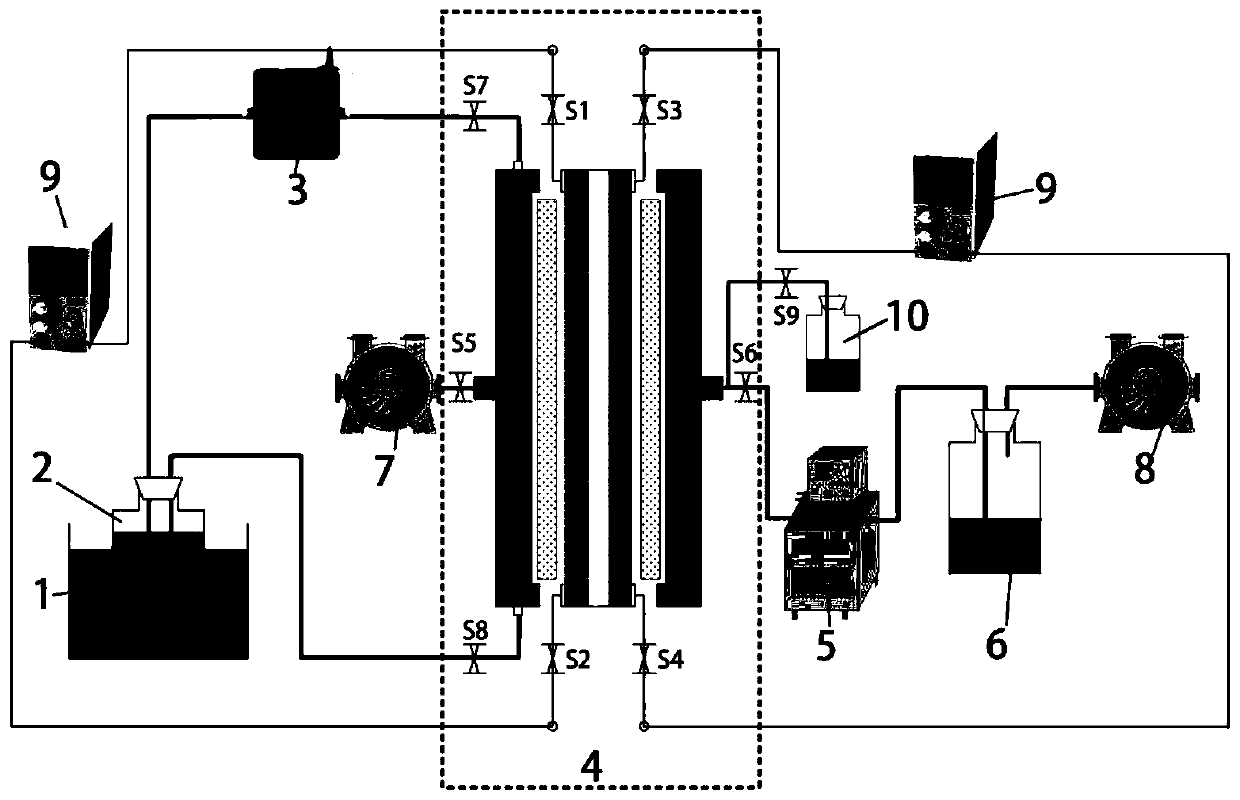

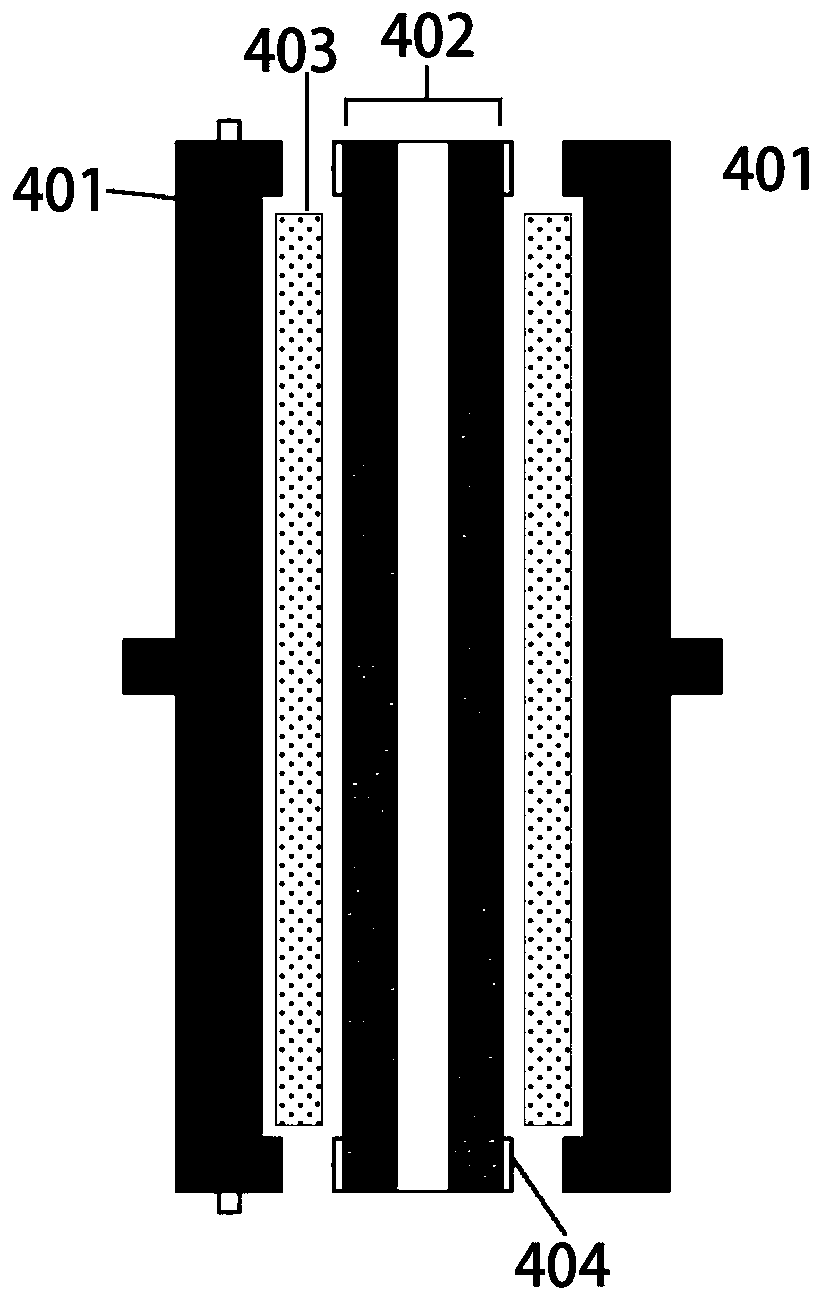

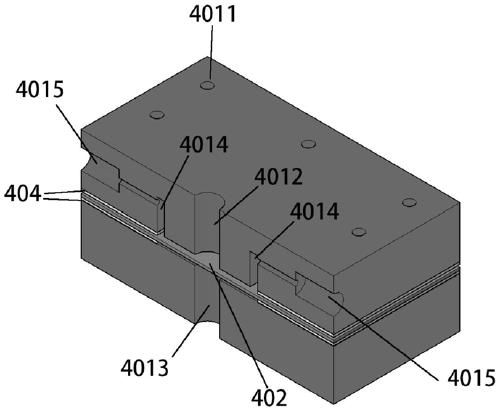

[0020] like Figure 1 to Figure 3 As shown, the present invention includes a vacuum membrane distillation reactor 4, one side of the vacuum membrane distillation reactor 4 is connected to the seawater side device, and the other side is connected to the fresh water side device. like figure 2 As shown, the vacuum membrane distillation reactor 4 includes two plexiglass plates 401, a dielectric wetting film 402, a flow guide net 403 and an electrode 404, and the dielectric wetting film 402 is installed in the middle of the two plexiglass plates 401, and the flow guide The net 403 is placed in the water flow channel between the plexiglass plate 401 and the dielectric wetting film 402 , and the electrodes 404 are attached to both ends of the dielectric wetting film 402 , four in total. The four motors are evenly connected to the power supply 9, and an electrode switch S1-S4 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com