Ceramic glaze with non-cracking glaze surface and glazing method thereof

A ceramic glaze and glaze technology, applied in the field of ceramic production, can solve problems such as failure to improve ornamental and artistic quality, glaze cracks, etc., and achieve the effects of improving chemical stability, decorativeness and artistry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A ceramic glaze with no cracks on the glaze surface, the glaze used for the ceramic glaze with no cracks on the glaze surface is made of the following raw materials in parts by mass:

[0038] 20g of spodumene, 20g of wollastonite, 25g of potassium feldspar, 15g of diatomaceous earth, 5g of titanium dioxide, 3g of borax, 2g of zinc oxide, 2g of iron oxide, 1g of boron oxide, 2g of zirconium silicate, 2g of zirconia, energy storage 5g of luminescent ingredients, 5g of silver star grains and appropriate amount of purified water.

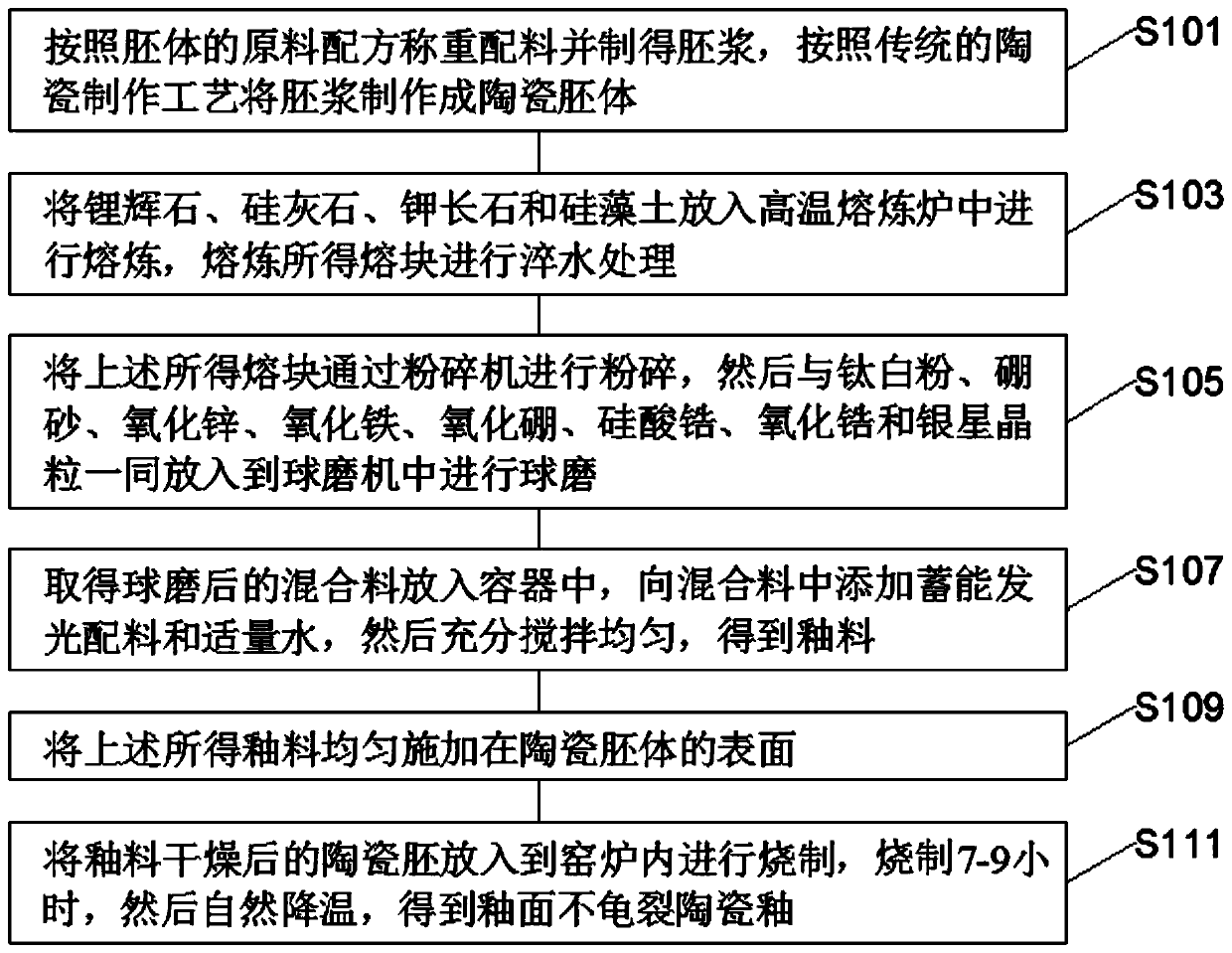

[0039] The preparation of the glaze-free ceramic glaze comprises the following steps:

[0040] According to the raw material formula of the embryo body, the ingredients are weighed and the embryo slurry is prepared, and the embryo slurry is made into a ceramic embryo body according to the traditional ceramic manufacturing process;

[0041] 20g of spodumene, 20g of wollastonite, 25g of potassium feldspar and 15g of diatomaceous earth are put into...

Embodiment 2

[0047] A ceramic glaze with no cracks on the glaze surface, the glaze used for the ceramic glaze with no cracks on the glaze surface is made of the following raw materials in parts by mass:

[0048] Spodumene 22.5g, wollastonite 25g, potassium feldspar 27.5g, diatomaceous earth 20g, titanium dioxide 6.5g, borax 4g, zinc oxide 3.5g, iron oxide 3.5g, boron oxide 3g, zirconium silicate 3g, oxide 3g of zirconium, 7.5g of energy storage and luminescent ingredients, 7.5g of silver star grains and appropriate amount of purified water.

[0049] The preparation of the glaze-free ceramic glaze comprises the following steps:

[0050] According to the raw material formula of the embryo body, the ingredients are weighed and the embryo slurry is prepared, and the embryo slurry is made into a ceramic embryo body according to the traditional ceramic manufacturing process;

[0051] 22.5g of spodumene, 25g of wollastonite, 27.5g of potassium feldspar and 20g of diatomaceous earth are put into ...

Embodiment 3

[0057] A ceramic glaze with no cracks on the glaze surface, the glaze used for the ceramic glaze with no cracks on the glaze surface is made of the following raw materials in parts by mass:

[0058] Spodumene 25g, wollastonite 30g, potassium feldspar 30g, diatomaceous earth 25g, titanium dioxide 8g, borax 5g, zinc oxide 5g, iron oxide 5g, boron oxide 5g, zirconium silicate 4g, zirconia 4g, energy storage 10g of luminescent ingredients, 10g of silver star grains and appropriate amount of purified water.

[0059] The preparation of the glaze-free ceramic glaze comprises the following steps:

[0060] According to the raw material formula of the embryo body, the ingredients are weighed and the embryo slurry is prepared, and the embryo slurry is made into a ceramic embryo body according to the traditional ceramic manufacturing process;

[0061] 25g of spodumene, 30g of wollastonite, 30g of potassium feldspar and 25g of diatomaceous earth are put into a high-temperature melting fur...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap