Special-shaped polyvinyl alcohol fiber reinforced cement-based composite material and preparation method thereof

A technology of polyvinyl alcohol fibers and composite materials, which is applied in the direction of fiber treatment, fiber chemical characteristics, single-component synthetic polymer rayon, etc., can solve the problems of durability and mechanical properties, and achieve the improvement of spinnability, The effect of good shape retention and small change in shear degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The special-shaped polyvinyl alcohol fiber reinforced cement-based composite material of this embodiment includes the following raw materials: cement, quartz sand, water reducing agent, special-shaped polyvinyl alcohol fiber and water, wherein the water-sand ratio is 1:1.8; the water-cement ratio is 0.4:1; Polyalkylene glycol monoacrylate water reducing agent is used, and the mixing amount is 0.1% by weight of water; the volume mixing amount of special-shaped polyvinyl alcohol fiber is 0.5% of the total volume of the composite material.

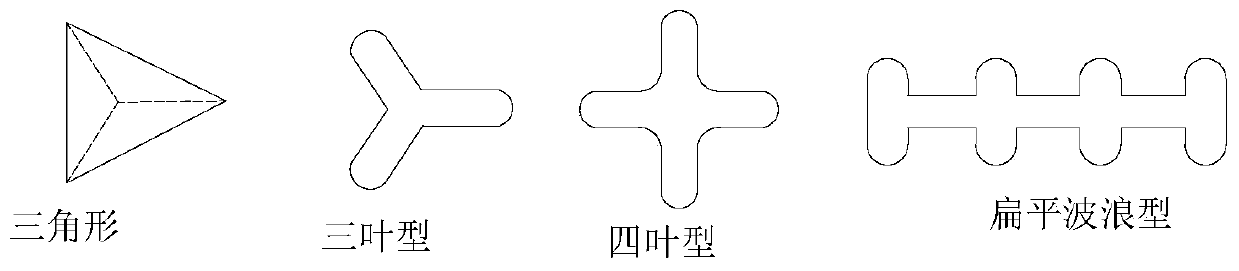

[0041] Among them, in the preparation of the special-shaped polyvinyl alcohol fiber, the special-shaped spinneret micropores of the spinneret adopt a four-lobe type, and the degree of irregularity is 50%. It includes the following steps:

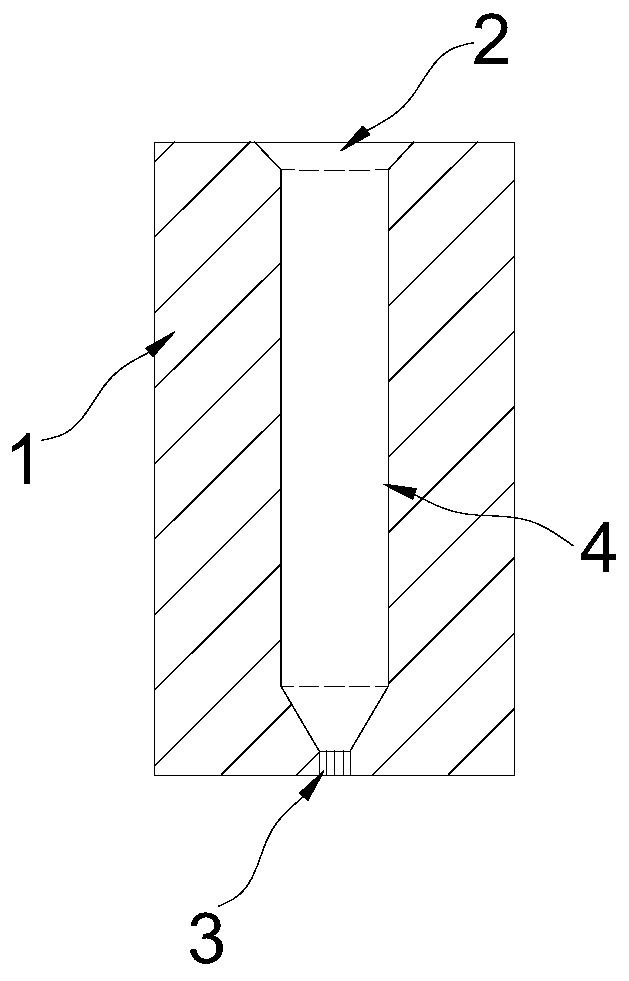

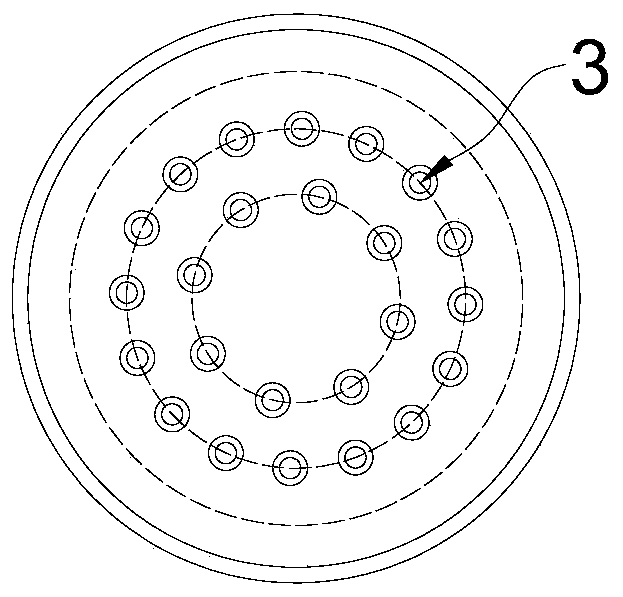

[0042] (I) The chemically modified polyvinyl alcohol powder is melt-spun on extrusion-spinning equipment, and after melt-extrusion, filtration and metering, it is ejected from the micro-holes of the speci...

Embodiment 2

[0050] The special-shaped polyvinyl alcohol fiber reinforced cement-based composite material of this embodiment includes the following raw materials: cement, quartz sand, water reducing agent, special-shaped polyvinyl alcohol fiber and water, wherein the water-sand ratio is 1:2; the water-cement ratio is 0.45:1; Polyalkylene glycol monomethacrylate water reducing agent is used, and the blending amount is 0.3wt% of water; the volume blending amount of special-shaped polyvinyl alcohol fiber is 1% of the total volume of the composite material.

[0051] Among them, in the preparation of the special-shaped polyvinyl alcohol fiber, the special-shaped spinneret micropores of the spinneret adopt a flat wave shape, and the degree of irregularity is 90%. It includes the following steps:

[0052] (I) The chemically modified polyvinyl alcohol powder is melt-spun on extrusion-spinning equipment, and after melt-extrusion, filtration and metering, it is ejected from the micro-holes of the special...

Embodiment 3

[0060] The special-shaped polyvinyl alcohol fiber reinforced cement-based composite material of this embodiment includes the following raw materials: cement, quartz sand, water reducing agent, special-shaped polyvinyl alcohol fiber and water, wherein the water-sand ratio is 1:2.2; the water-cement ratio is 0.5:1; use maleic anhydride and styrene copolymer water reducing agent, the mixing amount is 0.6wt% of water; the volume mixing amount of special-shaped polyvinyl alcohol fiber is 2% of the total volume of the composite material.

[0061] Among them, in the preparation method of the melt-spun special-shaped polyvinyl alcohol fiber, the special-shaped spinneret micropores of the spinneret adopt a trilobe type, and the degree of irregularity is 75%. It includes the following steps:

[0062] (I) The physically modified polyvinyl alcohol powder is melt-spun on extrusion-spinning equipment, and after melt-extrusion, filtration and metering, it is ejected from the micro-holes of the sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com