Machining process of showing stand

A processing technology and display rack technology, applied in the direction of coating, etc., can solve the problems of large surface grinding workload, lower product qualification rate, lower production efficiency, etc., achieve good protection effect, reduce the occurrence of defective products, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

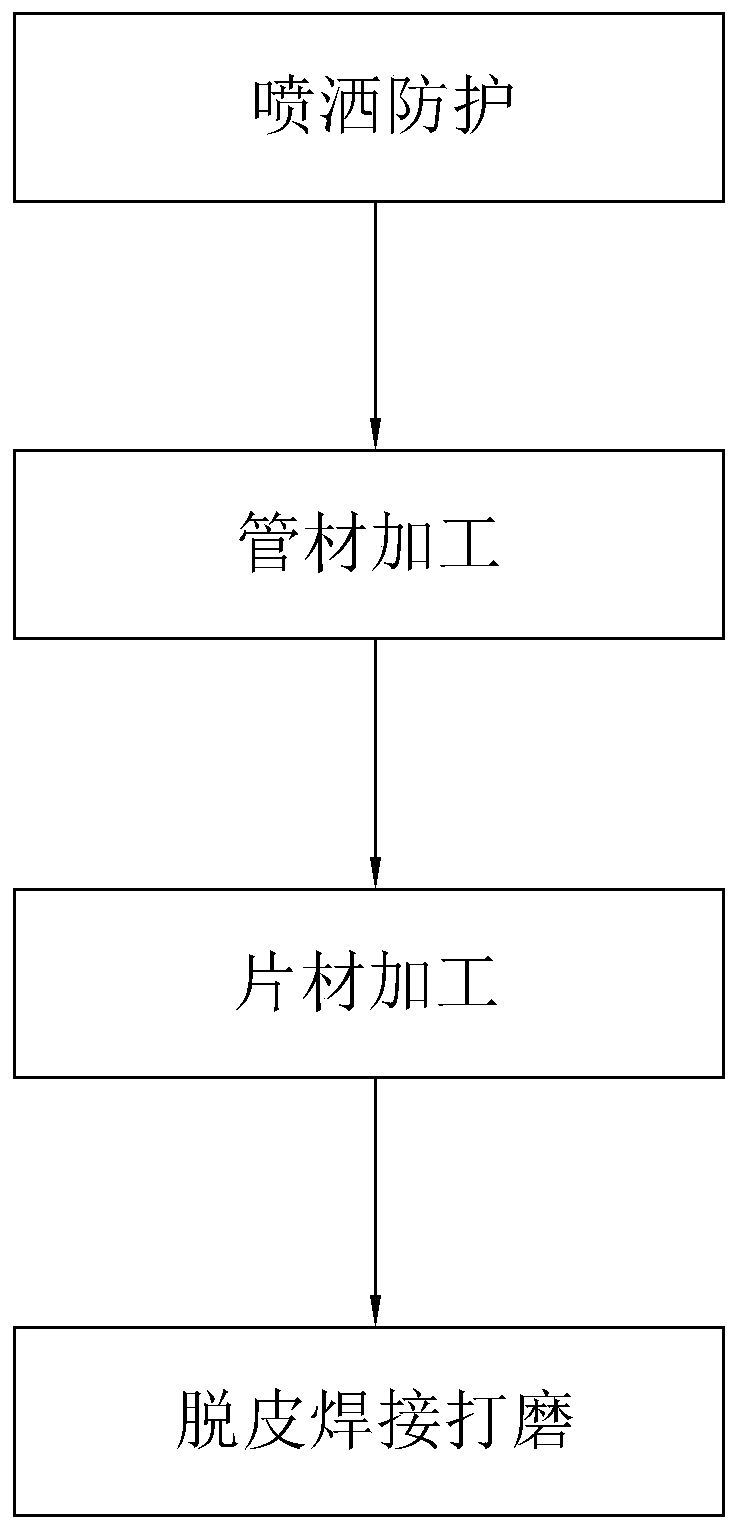

[0042] Embodiment 1: A processing technology of a display stand. The components of the protective liquid in step 1 and their corresponding parts by weight are shown in Table 1, and specifically include the following steps:

[0043] Step 1, spray protection, take the pipes and sheets used for processing and production, evenly spray protective liquid on the surface, and dry them to obtain the pretreated pipes and sheets;

[0044] Step 2, pipe processing, cutting, punching and bending the pretreated pipe according to the production drawings to obtain pipe fittings;

[0045]Step 3, sheet processing, cutting and bending the pretreated sheet according to the production drawings to obtain the sheet;

[0046] Step 4: Peeling, welding and grinding, peeling and cleaning the surface of the pipe fittings and pieces, then assembling them, and fixing them in the spot welding mold. After the automatic welding is completed, they are polished to obtain the display stand as shown in the product...

Embodiment 2-5

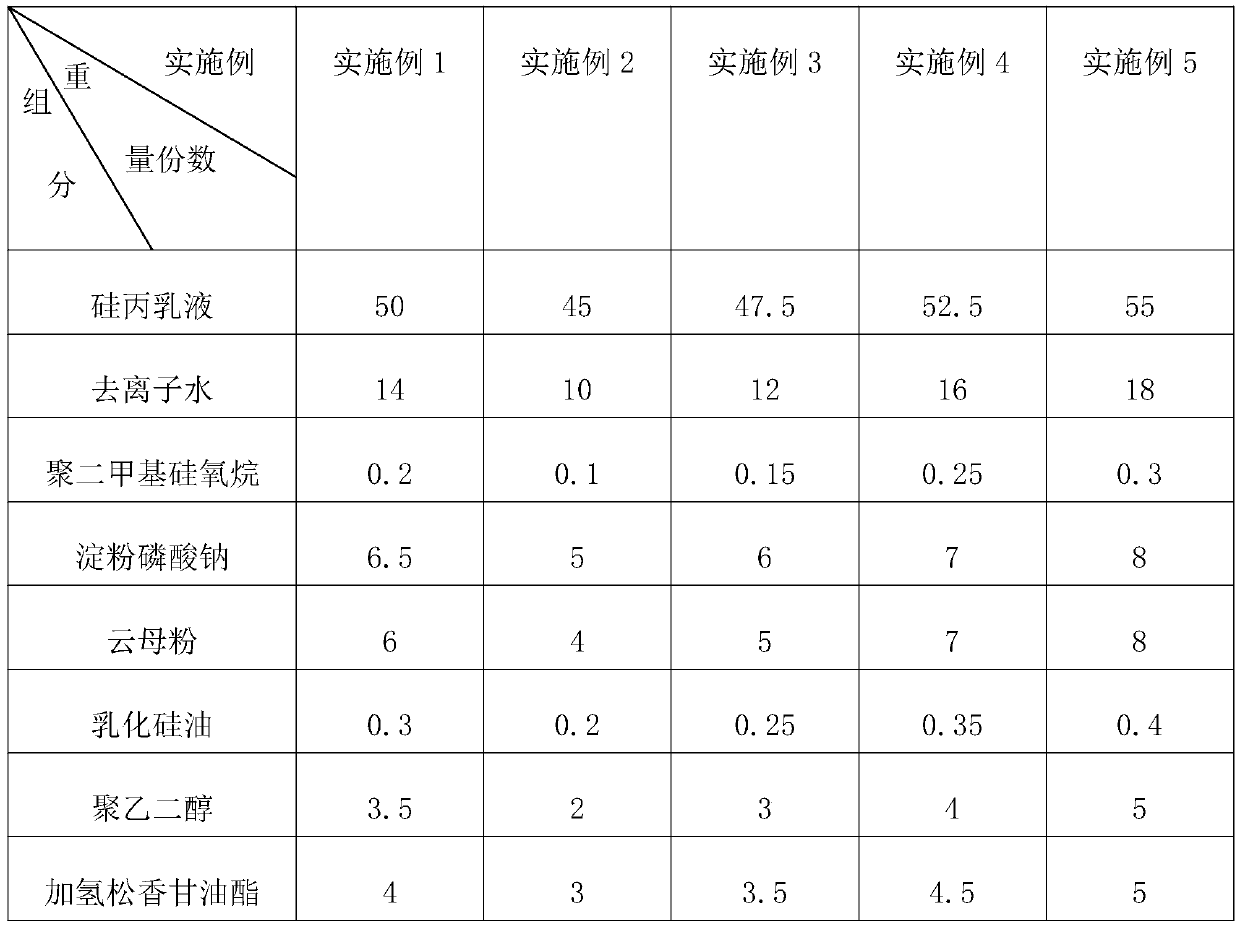

[0048] Embodiment 2-5: A processing technology of a display rack. The difference from Embodiment 1 is that the components of the protective liquid in Step 1 and their corresponding parts by weight are shown in Table 1.

[0049] Each component and parts by weight thereof in table 1 embodiment 1-5

[0050]

Embodiment 6

[0051] Embodiment 6: A processing technology of a display rack. The difference from Embodiment 1 is that the quality of polydimethylsiloxane in the protective liquid in step 1 is replaced by polyacrylic acid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com