Ionic liquid modified graphene composite anticorrosive wear-resistant coating and preparation method and application thereof

A graphene composite and ionic liquid technology, applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of reducing the corrosion resistance and poor dispersion of composite coatings, and achieve excellent corrosion resistance and wear resistance, Solve the effect of easy reunion and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] Another aspect of the embodiments of the present invention also provides the preparation method of the aforementioned ionic liquid modified graphene composite anti-corrosion and wear-resistant coating, which includes:

[0035] reacting 1-ethylimidazole with 1,8-dibromooctane to obtain an ionic liquid, and modifying the graphene with the ionic liquid to obtain the ionic liquid-modified graphene;

[0036] The ionic liquid modified graphene, curing agent, epoxy resin, and diluent are uniformly mixed to form the ionic liquid modified graphene composite anti-corrosion and wear-resistant coating.

[0037] In some more specific embodiments, the preparation method includes:

[0038] The mixed reaction system comprising 1-ethylimidazole, 1,8-dibromooctane and the first solvent is reacted at 80-90° C. for 5-10 hours, and then post-treated to obtain the ionic liquid.

[0039] Further, the first solvent includes ethanol, but is not limited thereto.

[0040] Further, the mass rati...

Embodiment 1

[0056] In this embodiment, the metal substrate is Q235 carbon steel, and the ionic liquid modified graphene composite anti-corrosion and wear-resistant coating is prepared on the surface of the carbon steel. The specific steps are as follows:

[0057] (1) 1-ethylimidazole and 1,8-dibromooctane were reacted in ethanol at 80°C for 10 hours, condensed and refluxed, and other reactant impurities were removed to obtain an ionic liquid (IL). The reaction route is as follows:

[0058]

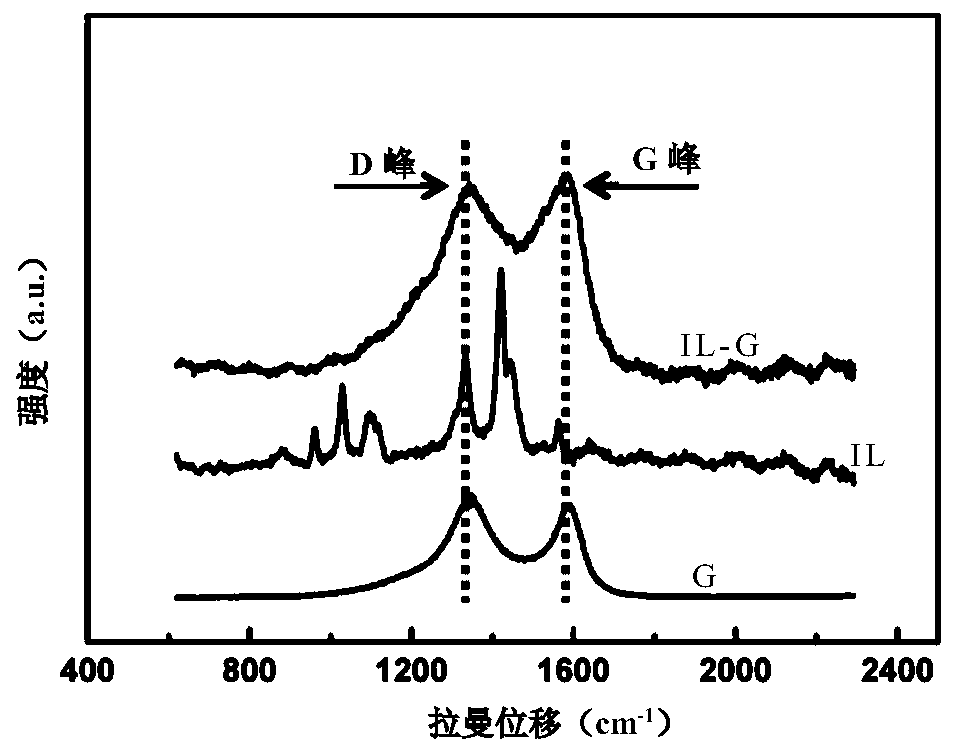

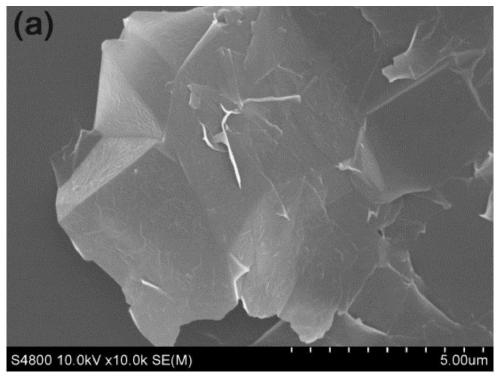

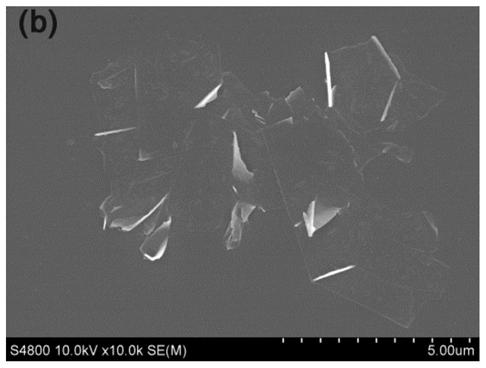

[0059] (2) 10 mg ionic liquid (IL) and 10 mg graphene (G) were dissolved in 20 ml of ethanol, and ultrasonically vibrated to prepare ionic liquid modified graphene (IL-G);

[0060] (3) Mix 0.1 parts by weight of ionic liquid modified graphene with 10 parts by weight of polyamide water-based curing agent to form component 1; get 40 parts by weight of epoxy resin E51 and 1 part by weight of xylene diluent to mix to form component 1 Divide into two; mix component one and component two to prepare ionic...

Embodiment 2

[0064] In this embodiment, the metal substrate is Q235 carbon steel, and the ionic liquid modified graphene composite anti-corrosion and wear-resistant coating is prepared on the surface of the carbon steel. The specific steps are as follows:

[0065] (1) 1-ethylimidazole and 1,8-dibromooctane were reacted in ethanol at 90°C for 5 hours, condensed and refluxed, and other reactant impurities were removed to obtain an ionic liquid;

[0066] (2) 20mg ionic liquid and 10mg graphene powder were dissolved in 20ml of ethanol, and ultrasonically vibrated to obtain ionic liquid modified graphene;

[0067] (3) Mix 0.1 parts by weight of ionic liquid modified graphene with 10 parts by weight of polyamide water-based curing agent to form component 1; get 40 parts by weight of epoxy resin E51 and 1 part by weight of xylene diluent to mix to form component 1 Divide into two; mix component one and component two to prepare ionic liquid modified graphene composite anti-corrosion and wear-resis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com