Elastic composite fiber and preparation method thereof

A technology of elastic composite fiber and composite structure, applied in fiber processing, fiber chemical characteristics, rayon manufacturing, etc., can solve the problems of unpublished fiber quick-drying performance, poor moisture conductivity, unpublished fiber water absorption and quick-drying test data, etc. Achieve excellent water absorption and quick-drying performance, good moisture-wicking and quick-drying performance, and excellent spinnability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

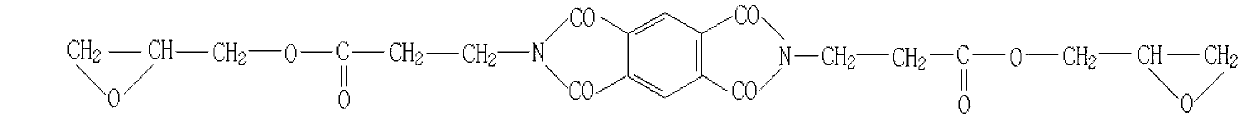

Image

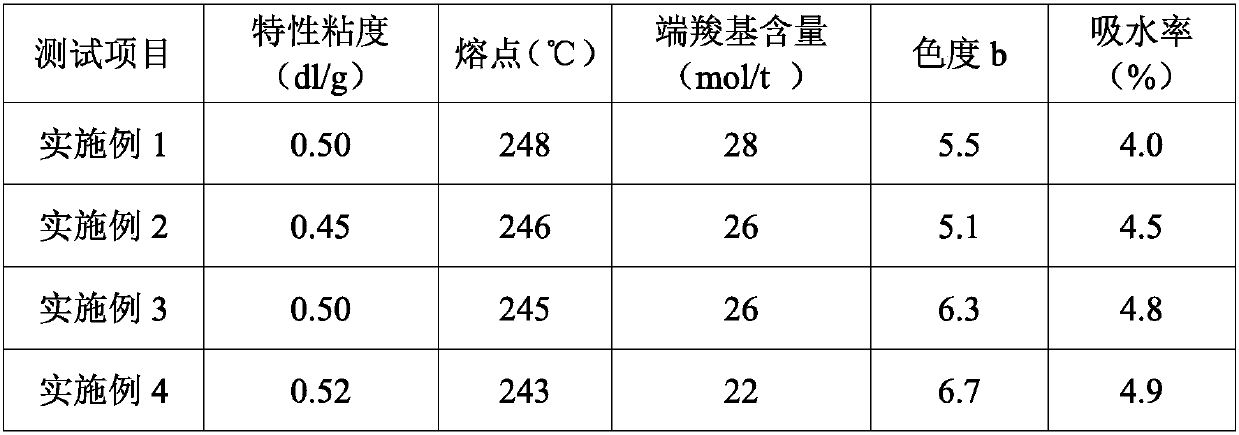

Examples

Embodiment 1

[0034] (1) Preparation of water-absorbing modified PET slices: Calculate the mass of theoretically produced water-absorbing modified PET, weigh terephthalic acid, ethylene glycol and isosorbide with an acid-alcohol molar ratio of 1:1.35 and add them to the reaction kettle for esterification reaction, the addition of isosorbide is 0.5%, the esterification temperature is 252°C, the esterification pressure is a slight positive pressure of 0.02MPa, and the esterification rate reaches more than 98%. Alcohol, 0.1% modified accelerator, 100ppm trimethyl phosphate, 1500ppm antioxidant 1425 and 0.3% matting agent titanium dioxide, after equilibrating for 30min, add 40ppm catalyst titanium glycolate, heat up to 278°C, and vacuumize at the same time to make the vacuum degree at Below 80Pa, let the esterified product undergo polycondensation reaction under vacuum conditions, stop the reaction after the stirring current and the online viscometer value reach the preset value, extrude and cut...

Embodiment 2

[0037] (1) Preparation of water-absorbing modified PET slices: Calculate the mass of theoretically produced water-absorbing modified PET, weigh terephthalic acid, ethylene glycol and isosorbide with an acid-alcohol molar ratio of 1:1.2 and add them to the reaction kettle for esterification reaction, the addition of isosorbide is 0.3%, the esterification temperature is 248°C, the esterification pressure is a slight positive pressure of 0.02MPa, and the esterification rate reaches more than 98%. Alcohol, 0.1% modified accelerator, 150ppm trimethyl phosphate, 2500ppm antioxidant 1425 and 0.3% matting agent titanium dioxide, after equilibrating for 30 minutes, add 30ppm catalyst titanium glycolate, heat up to 276 ° C, and vacuumize at the same time to make the vacuum degree Below 80Pa, let the esterified product undergo polycondensation reaction under vacuum conditions, stop the reaction after the stirring current and the online viscometer value reach the preset value, extrude and ...

Embodiment 3

[0040] (1) Preparation of water-absorbing modified PET slices: Calculate the mass of theoretically produced water-absorbing modified PET, weigh terephthalic acid, ethylene glycol and isosorbide with an acid-alcohol molar ratio of 1:1.2 and add them to the reaction kettle for esterification reaction, the amount of isosorbide added is 0.1%, the esterification temperature is 250°C, the esterification pressure is a slight positive pressure of 0.02MPa, and the esterification rate reaches more than 98%. Alcohol, 0.8% modified accelerator, 150ppm trimethyl phosphate, 2800ppm antioxidant 1425 and 0.3% matting agent titanium dioxide, after equilibrating for 10min, add 50ppm catalyst titanium glycolate, heat up to 278°C, and vacuumize at the same time to make the vacuum degree at Below 80Pa, let the esterified product undergo polycondensation reaction under vacuum conditions, stop the reaction after the stirring current and the online viscometer value reach the preset value, extrude and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com