Method and system for recovering glyphosate synthesis liquid hydrolysis tail gas

A recovery method and a technology for synthesizing liquids, applied in separation methods, chemical instruments and methods, steam condensation, etc., can solve problems such as waste of heat, waste of heat from hydrolysis steam, and excessive equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

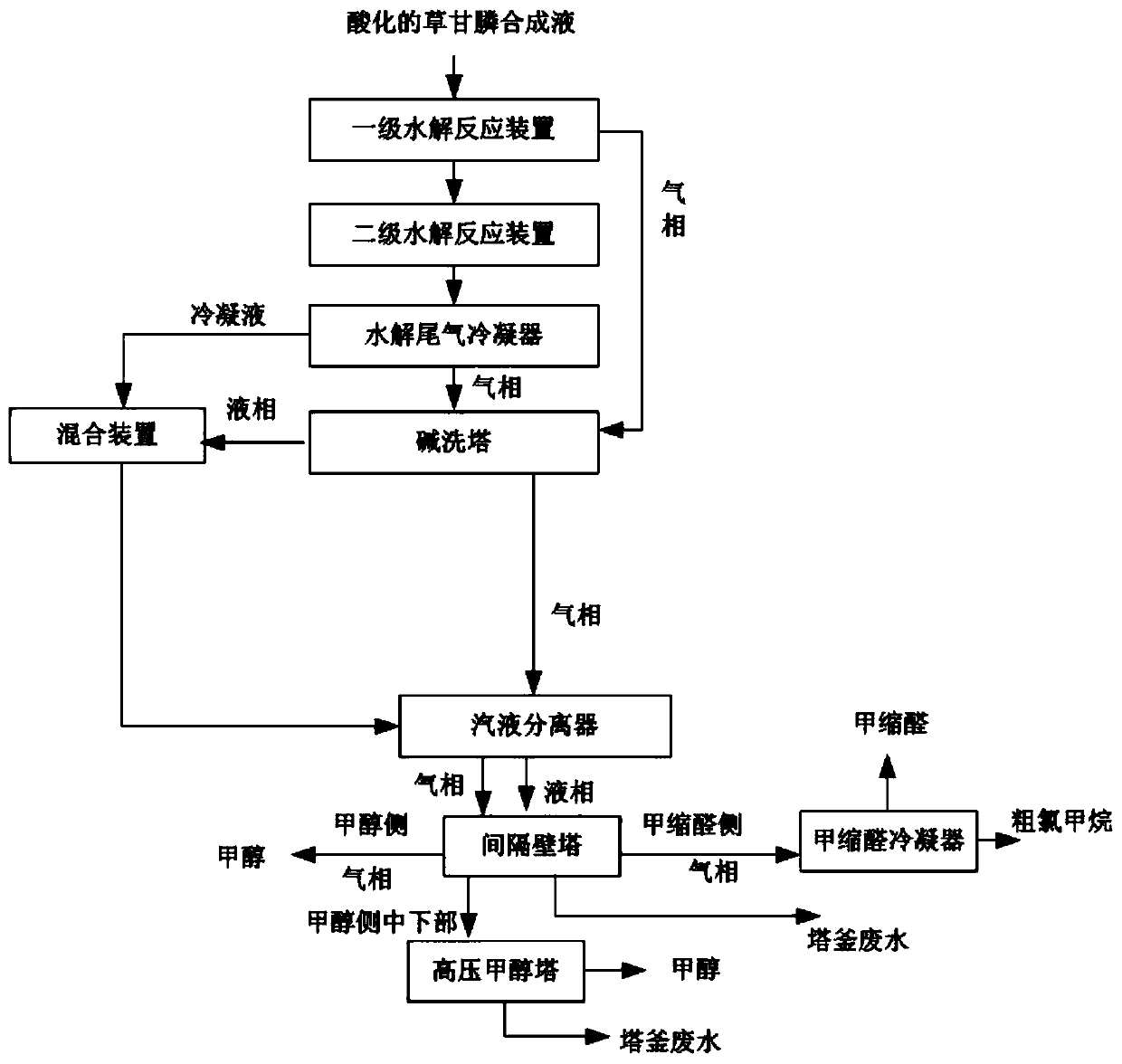

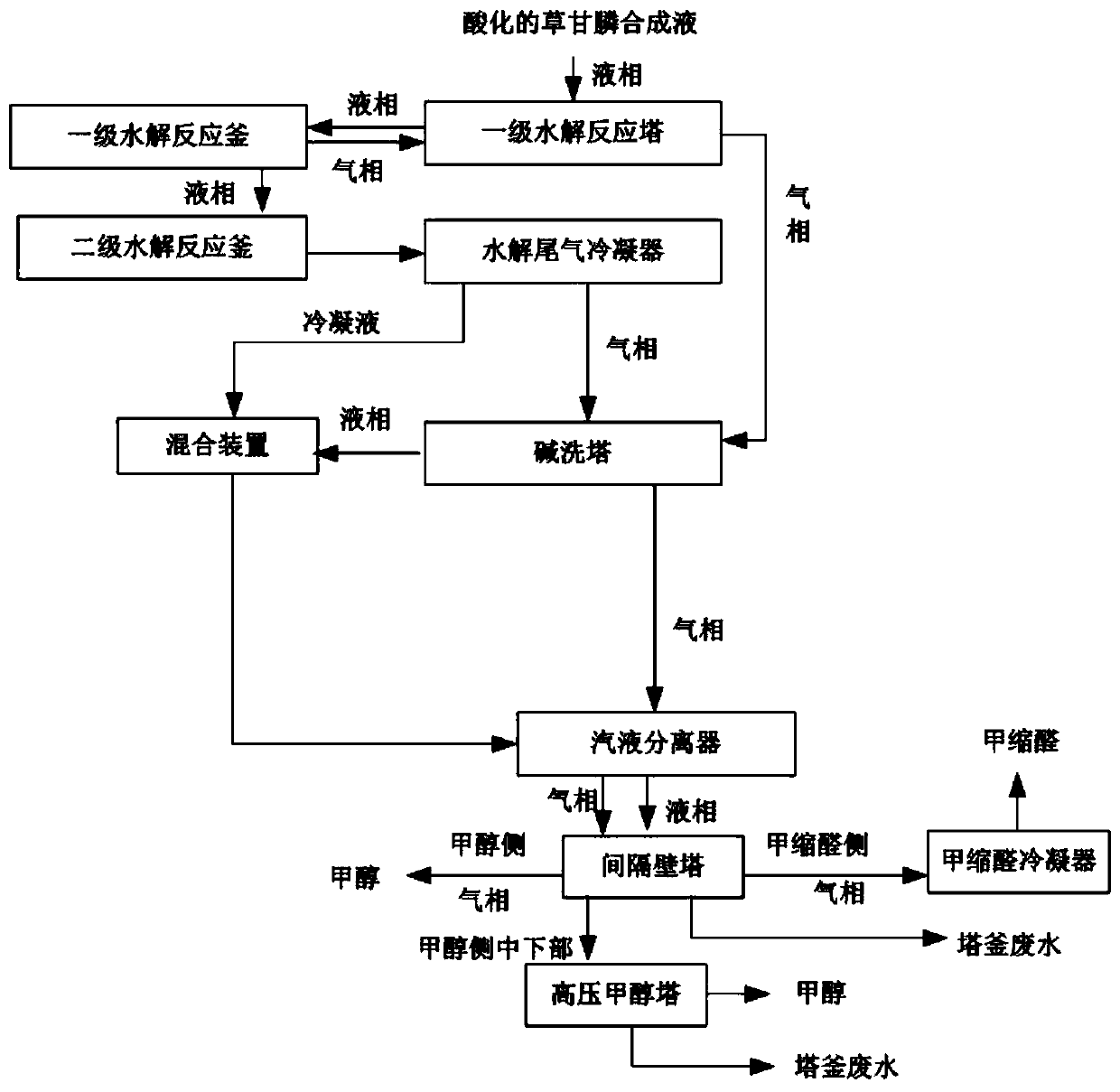

Image

Examples

Embodiment 1

[0124] exist figure 2 Experiments are carried out on the recovery system of the hydrolysis tail gas of the glyphosate synthetic liquid:

[0125] Synthesize glyphosate synthetic liquid in the synthesis kettle:

[0126] The raw materials include: 5200 parts by weight of methanol, 1630 parts by weight of triethylamine, 950 parts by weight of paraformaldehyde, 1200 parts by weight of glycine and 2060 parts by weight of dimethyl phosphite.

[0127] a1) Carrying out depolymerization reaction of methanol, triethylamine and paraformaldehyde at 45°C;

[0128] a2) adding the product after the depolymerization reaction to glycine at 50°C;

[0129] a3) Condensing the product after the addition reaction with dialkyl phosphite at 50° C. to obtain a synthesis liquid.

[0130] The synthetic solution and hydrochloric acid are mixed in an acidification device (static mixer) for acidification. The acidification temperature is 50°C and the pressure is 0KPa. After acidification is complete, c...

Embodiment 2

[0139] exist figure 2 Experiments are carried out on the continuous synthesis system of the glyphosate:

[0140] Synthesize glyphosate synthetic liquid in the synthesis kettle:

[0141] The raw materials include: 5400 parts by weight of methanol, 1650 parts by weight of triethylamine, 950 parts by weight of paraformaldehyde, 1250 parts by weight of glycine and 2100 parts by weight of dimethyl phosphite.

[0142] a1) Carrying out depolymerization reaction of methanol, triethylamine and paraformaldehyde at 50°C;

[0143] a2) adding the product after the depolymerization reaction to glycine at 45°C;

[0144] a3) Condensing the product after the addition reaction with dialkyl phosphite at 45° C. to obtain a synthesis liquid.

[0145] The synthetic liquid and hydrochloric acid are mixed in an acidification device (static mixer) for acidification. The acidification temperature is 40° C. and the pressure is 5KPa. After acidification is complete, cool in an acidification cooler. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com