Aluminum nitride and boron nitride composite ceramic material and preparation method thereof

A composite ceramic and boron nitride technology, applied in glass manufacturing equipment, manufacturing tools, glass molding, etc., can solve problems such as poor oxidation resistance, and achieve high flexural flexural strength, good thermal conductivity and flexural resistance. Effect of strength, high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

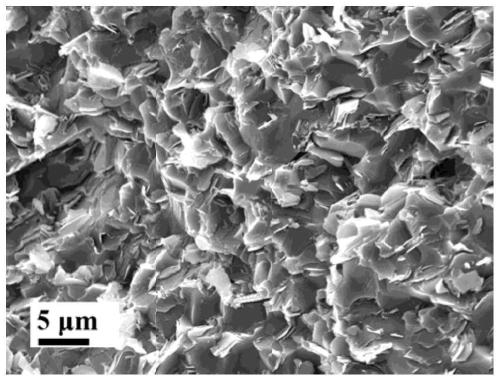

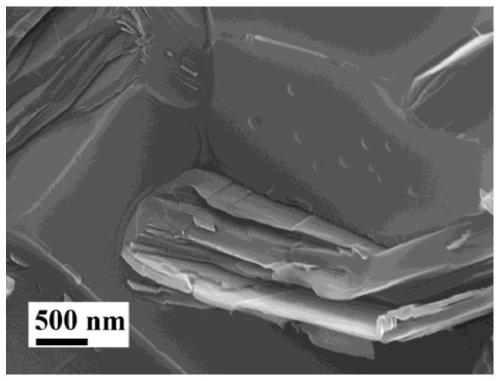

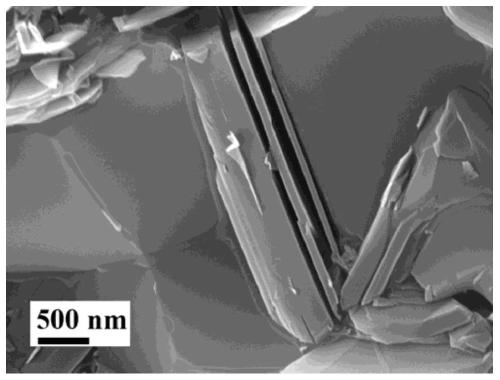

Image

Examples

Embodiment 1

[0039] Put 80 grams of aluminum nitride powder and 20 grams of boron nitride powder into a nylon ball mill jar, add alcohol and alumina balls and seal them, and then ball mill for 10 hours. The amount of alcohol used should not exceed 2 / 2 of the volume of the nylon ball mill jar. 3. The amount of alumina grinding balls used is twice the total mass of the mixed powder, and a slurry is formed after ball milling. Put the slurry in a vacuum oven at 60° C. for 8 hours to vacuum-dry to obtain aluminum nitride boron nitride composite powder. The composite powder is hot-pressed and sintered. The sintering temperature is 1820°C, and the temperature is kept for 5 hours. The sintering pressure is increased to 20MPa within 10 minutes after the temperature rises. The nitrogen pressure is kept at 1.2KPa to 1.6KPa, and the aluminum nitride boron nitride composite ceramic material is obtained after sintering. Aluminum nitride boron nitride ceramics are processed and polished according to cus...

Embodiment 2

[0042] Put 75 grams of aluminum nitride powder and 25 grams of boron nitride powder into a nylon ball mill jar, add alcohol and alumina balls and seal them, and then ball mill for 8 hours. The amount of alcohol used should not exceed 2 / 2 of the volume of the nylon ball mill jar. 3. The amount of alumina grinding balls used is twice the total mass of the mixed powder, and a slurry is formed after ball milling. Put the slurry in a vacuum oven at 60° C. for 6 hours to vacuum-dry to obtain aluminum nitride boron nitride composite powder. The composite powder is hot-pressed and sintered, the sintering temperature is 1780°C, and the temperature is kept for 8 hours. The sintering pressure is increased to 25MPa within 10 minutes after the temperature rises, and the pressure is released when the heat preservation is completed and the temperature drops to 1200°C. The nitrogen pressure is kept at 1.2KPa to 1.6KPa, and the aluminum nitride boron nitride composite ceramic material is obtai...

Embodiment 3

[0045] Put 70 grams of aluminum nitride powder and 30 grams of boron nitride powder into a nylon ball mill jar, add alcohol and alumina balls and seal them, and then perform ball milling for 8 hours. The amount of alcohol used should not exceed 2 / 2 of the volume of the nylon ball mill jar. 3. The amount of alumina grinding balls used is twice the total mass of the mixed powder, and a slurry is formed after ball milling. Put the slurry in a vacuum oven at 60° C. for 6 hours to vacuum-dry to obtain aluminum nitride boron nitride composite powder. The composite powder is hot-pressed and sintered. The sintering temperature is 1800°C, and the temperature is kept for 4 hours. The sintering pressure is increased to 25MPa within 10 minutes after the temperature rises. The nitrogen pressure is kept at 1.2KPa to 1.6KPa, and the aluminum nitride boron nitride composite ceramic material is obtained after sintering. Aluminum nitride boron nitride ceramics are processed and polished accord...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com