Preparation method of amino acid foliar fertilizer

A foliar fertilizer and amino acid technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, nitrogen fertilizer, etc., can solve the problems of poor pertinence, low content of functional nutritional factors, and differences in amino acid components of different crop nutritional characteristics Major problems, to achieve the effect of solving environmental pollution and waste of resources, overcoming the deterioration of amino acids, and improving the high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Mix and stir corn steep liquor and γ-aminobutyric acid fermentation waste liquid according to the ratio of 1:3, add molasses in a ratio of 3%, and obtain the fermentation medium; The addition ratio is 3.5: 2: 4.5 and mixed uniformly to obtain mixed flora seed liquid; the mixed flora seed liquid is inoculated into the shake flask co-culture medium in an amount of 3%, and the bacterial concentration reaches the logarithmic growth phase to obtain first-class seeds; 8% of the total amount of the first-grade seed strains was inoculated into a 100L seed tank to expand and cultivate to obtain the second-grade seeds; 10% of the total amount of the second-grade seed strains was inoculated into the fermentation medium to ferment, at a temperature of 28°C and a stirring speed of After fermentation and cultivation for 55 hours under the conditions of 120r / min and 3L / min aeration, the fermentation broth was collected. Finally, the fermentation liquid is separated by a decanter centr...

Embodiment 2

[0031]Mix and stir corn steep liquor and γ-aminobutyric acid fermentation waste liquid according to the ratio of 1:10, add molasses at a ratio of 1%, to obtain a fermentation medium; The addition ratio is 5: 2: 3 and the mixed flora seed liquid is uniformly mixed; the mixed flora seed liquid is inoculated into the shake flask co-culture medium in an amount of 5%, and the bacterial concentration reaches the logarithmic growth phase to obtain first-class seeds; 10% of the total bacterial strains of the first-grade seeds are inoculated into a 100L seed tank to expand and cultivate to obtain secondary seeds; 5% of the total bacterial strains of the secondary seeds are inoculated into the fermentation medium for fermentation, at a temperature of 35°C and a stirring speed of After 60 hours of fermentation and cultivation under the conditions of 200r / min and an aeration rate of 5L / min, the fermentation liquid was collected. Finally, the fermentation liquid is separated by a decanter ...

Embodiment 3

[0033] The steps are the same as in Example 1, except that the fermentation temperature is 33°C, the stirring speed is 160r / min, and the time is 58h. After testing, the prepared amino acid foliar fertilizer contains 1.2% of active polypeptide content, 14% of total amino acid content, 0.6% of γ-aminobutyric acid content, 3.5% of glutamic acid content, 3.1% of threonine content, and 3.1% of arginine content. 1.5%, proline content 0.6%, serine content 2%, tyrosine content 0.8%, other amino acid content 3.6%.

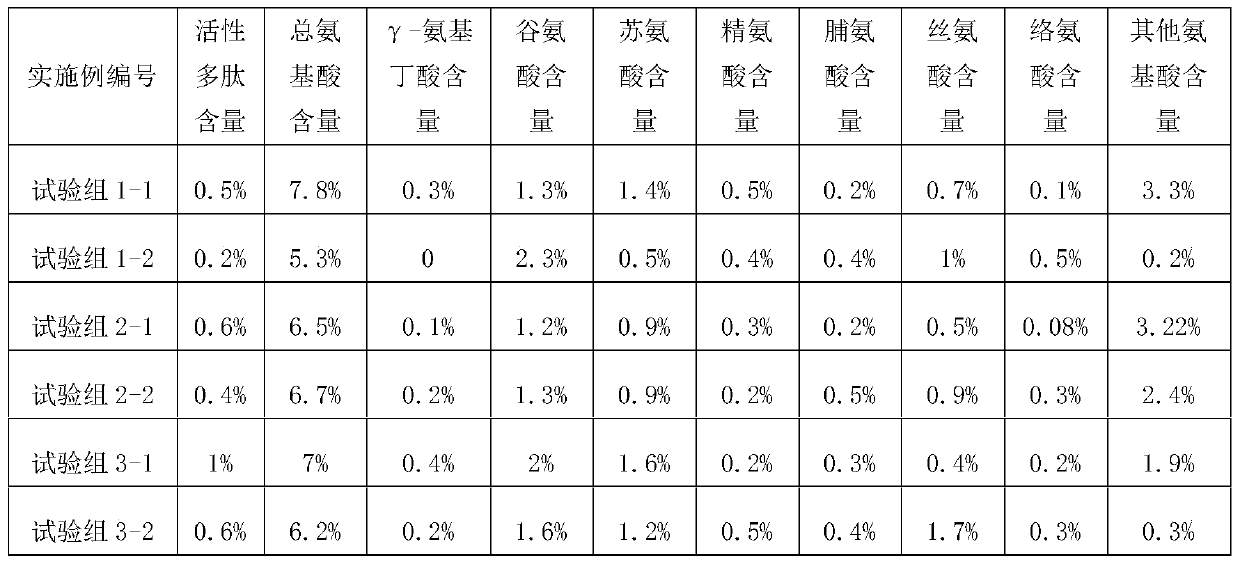

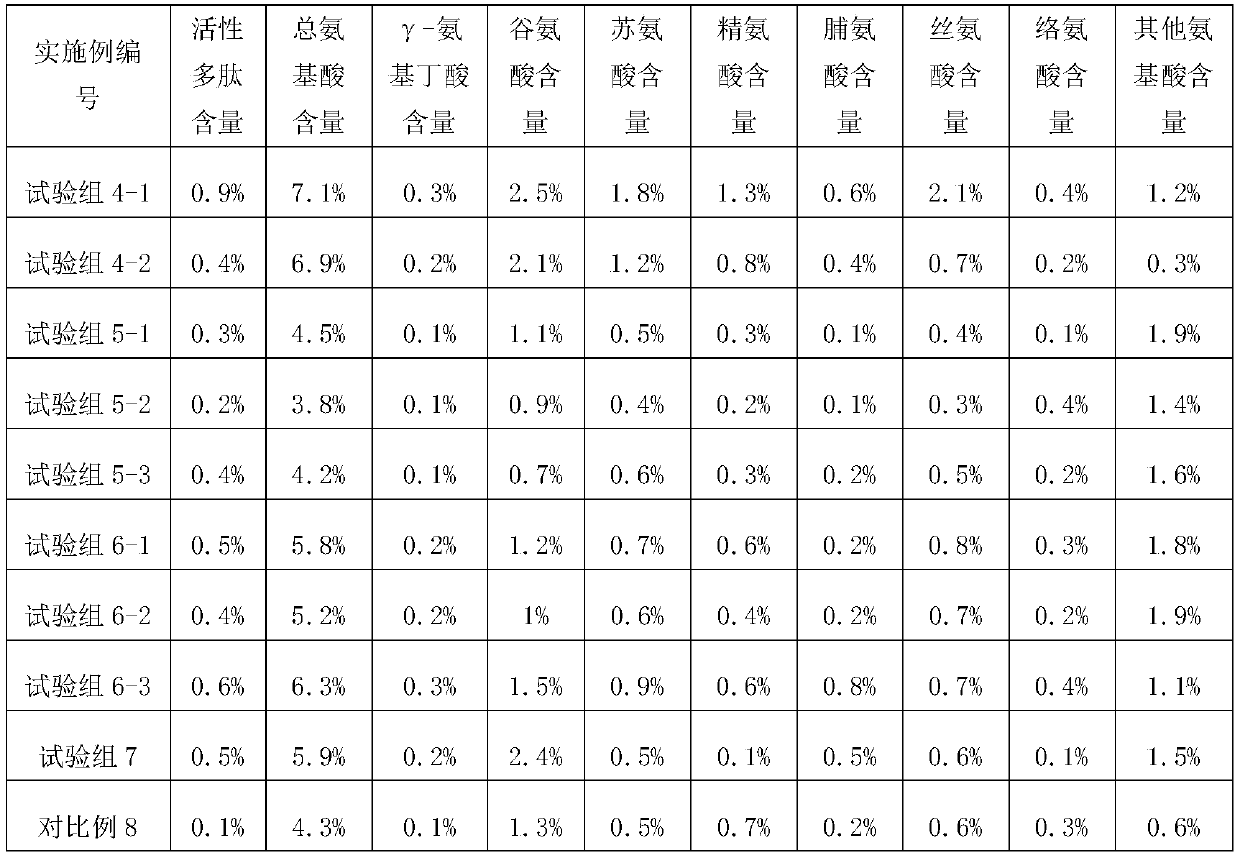

[0034] Investigate the content of various amino acids and active polypeptides in the amino acid foliar fertilizer prepared by the mass ratio between the fermentation medium raw material, the fermentation medium raw material, and the mass percentage of added molasses, as follows:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com