Method for preparing isooctane by isobutene superposition-hydrogenation

A technology for isobutene and isooctane, applied in the field of isobutene superposition-hydrogenation to prepare isooctane, can solve the problem of not involving isooctane and the like, and achieve the effects of shortening residence time, long service life of catalyst and simplifying process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

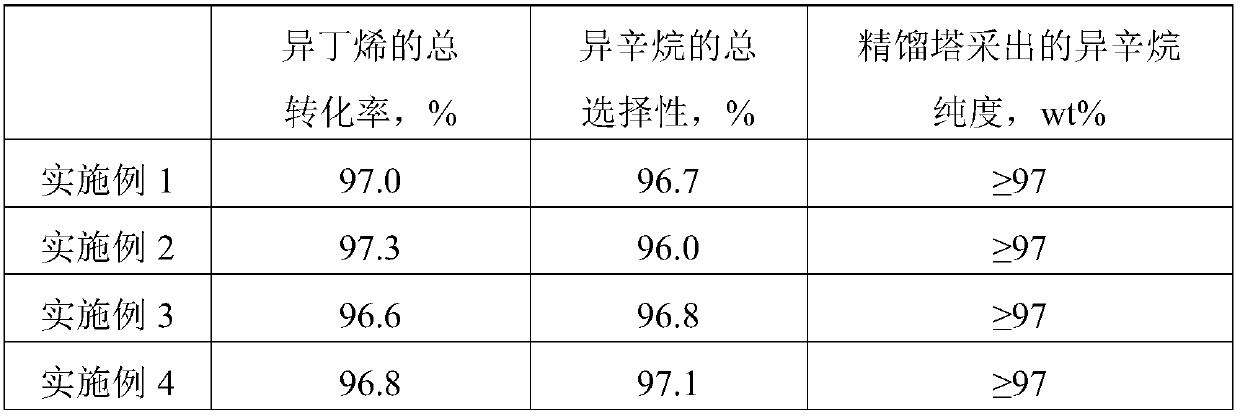

Embodiment 1

[0050] Fill 50mL γ-Al into the fixed bed reactor 2 o 3 The catalyst of loading Pd and styrene-divinylbenzene macroporous sulfonic acid resin, the dry base acid content of this catalyst is 3.1mol H + / kg, the dry basis Pd content is 0.5wt%. The specific surface area of the catalyst is 40m 2 / g, the pore volume is 0.25mL / g, and the average pore diameter is 31nm. The catalyst was activated for 8 hours at a temperature of 110 °C, a pressure of 0.5 MPa, and a hydrogen flow rate of 4 mL / (min·mL catalyst) to complete the reduction and activation treatment. The raw material was mixed hydrocarbons with a weight ratio of isooctane / isobutene of 5:1. Based on the weight of the raw material, add 10wt% of isopropyl ether to the raw material as a dimer selectivity regulator, mix it evenly, and mix it with the hydrogen flow, at a temperature of 80°C, a pressure of 0.8MPa, and a hydrogen / isobutylene molar ratio 2.0 and the volumetric space velocity of fresh raw material is 3.0h -1 Under...

Embodiment 2

[0052] Use "methacrylic anhydride-methacrylic acid methanol macroporous sulfonic acid resin catalyst" to replace the "styrene-divinylbenzene macroporous sulfonic acid resin catalyst" in Example 1, and the remaining reaction conditions are the same as in Example 1 to start the reaction . The specific reaction results are shown in Table 1.

Embodiment 3

[0054]The "bisphenol-methacrylic acid epoxy macroporous sulfonic acid resin catalyst" was used to replace the "styrene-divinylbenzene macroporous sulfonic acid resin catalyst" in Example 1, and the rest of the reaction conditions were the same as in Example 1 to start the reaction. The specific reaction results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com