Self-repairable, high-strength and antibacterial soybean protein film and preparation method thereof

A technology of soybean protein and soybean protein isolate, which is applied in the field of preparation of self-healing, high-strength, antibacterial soybean protein films, to achieve the effects of enhanced interaction, excellent mechanical properties, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

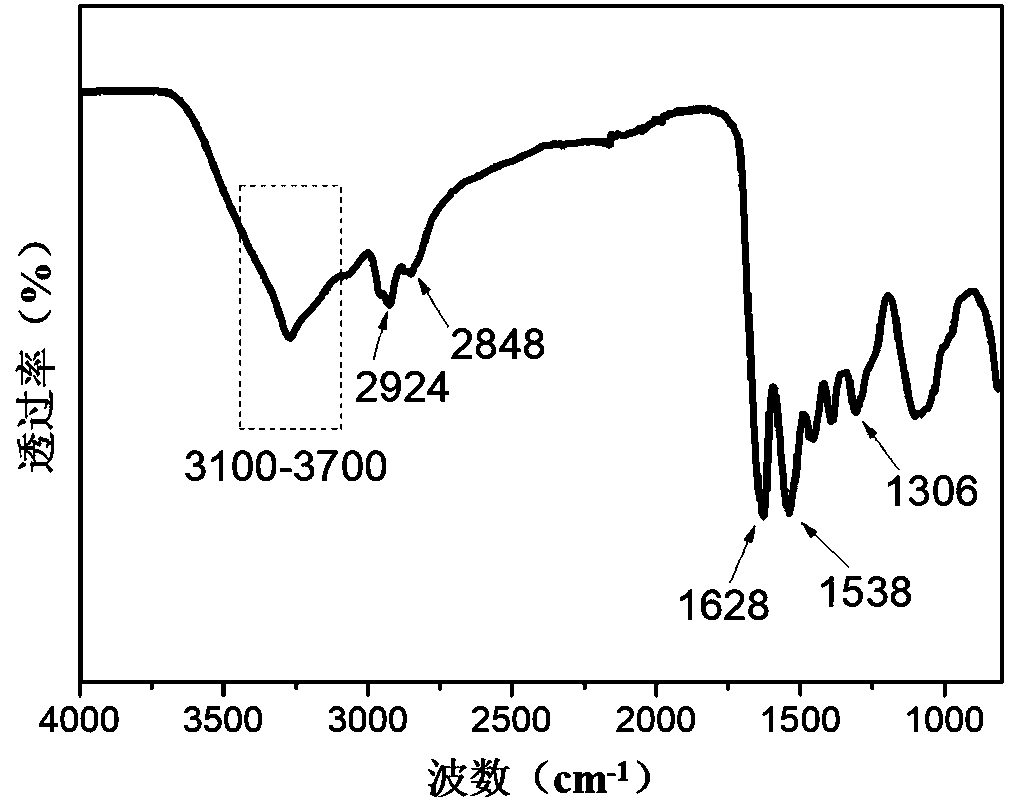

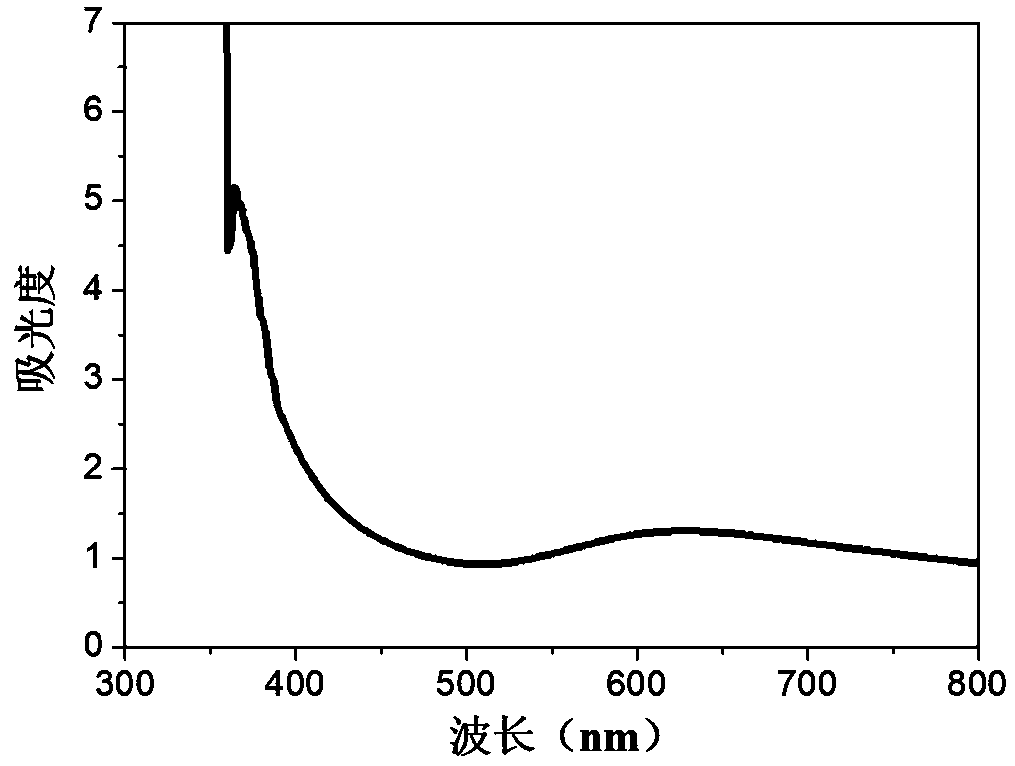

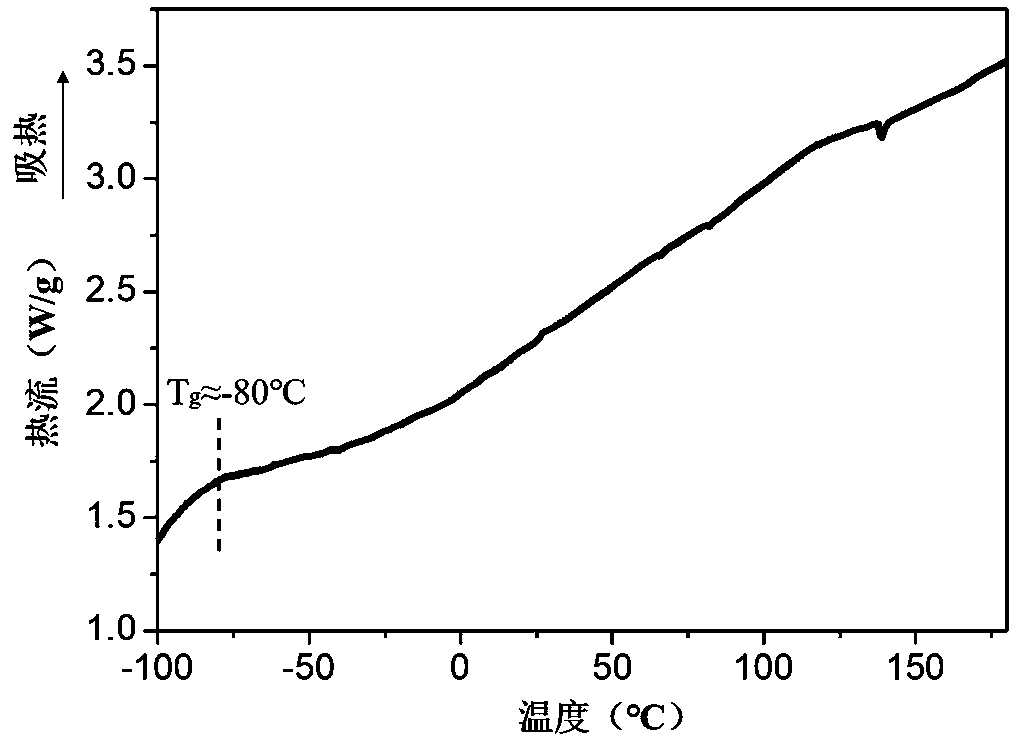

Method used

Image

Examples

Embodiment 1

[0036] The present embodiment provides a method for preparing a self-healing, high-strength, antibacterial soybean protein film, and the soybean protein film is prepared according to the following weight ratios:

[0037] Soy Protein Isolate 1.5g

[0038] Polyethyleneimine 1.5g

[0039] Anhydrous copper sulfate 0.06g

[0040] Distilled water 57g

[0041] The preparation method steps are as follows:

[0042] (1) Mix soybean protein isolate, polyethyleneimine and distilled water according to the proportion of the prepared materials, and use a high-pressure homogenizer to homogenize and emulsify for 10 minutes under the action of 30MPa pressure and 0.5MPa emulsifying force; then stir at 85 °C 30 min, fully stirred to form a mixed solution;

[0043] (2) Dissolve 6-12 parts of anhydrous copper sulfate in 10 g of water and add dropwise to the above mixed solution, ultrasonicate for 30 min, and then stir at 50 °C for 1 h until uniform;

[0044] (3) Pour the sonicated solution int...

Embodiment 2

[0047] The present embodiment provides a method for preparing a self-healing, high-strength, antibacterial soybean protein film, and the soybean protein film is prepared according to the following weight ratios:

[0048] Soy Protein Isolate 1.5g

[0049] Polyethyleneimine 1.5g

[0050] Anhydrous copper sulfate 0.09g

[0051] Distilled water 57g

[0052] The preparation method steps are as follows:

[0053] (1) Mix soybean protein isolate, polyethyleneimine and distilled water according to the proportion of the prepared materials, and use a high-pressure homogenizer to homogenize and emulsify for 10 minutes under the action of 30MPa pressure and 0.5MPa emulsifying force; then stir at 85 °C 30 min, fully stirred to form a mixed solution;

[0054] (2) Dissolve 6-12 parts of anhydrous copper sulfate in 10 g of water and add dropwise to the above mixed solution, ultrasonicate for 30 min, and then stir at 50 °C for 1 h until uniform;

[0055](3) Pour the sonicated solution into...

Embodiment 3

[0064] The present embodiment provides a method for preparing a self-healing, high-strength, antibacterial soybean protein film, and the soybean protein film is prepared according to the following weight ratios:

[0065] Soy Protein Isolate 1.5g

[0066] Polyethyleneimine 1.5g

[0068] Distilled water 57g

[0069] The preparation method steps are as follows:

[0070] (1) Mix soybean protein isolate, polyethyleneimine and distilled water according to the proportion of the prepared materials, and use a high-pressure homogenizer to homogenize and emulsify for 10 minutes under the action of 30MPa pressure and 0.5MPa emulsifying force; then stir at 85 °C 30 min, fully stirred to form a mixed solution;

[0071] (2) Dissolve 6-12 parts of zinc chloride in 10 g of water, add dropwise to the above mixed solution, ultrasonicate for 30 min, and then stir at 50 °C for 1 h until uniform;

[0072] (3) Pour the sonicated solution into a polytetrafluoroethyle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com