Silver intercalation gating device based on hafnium oxide conversion layer and manufacturing method of gating device

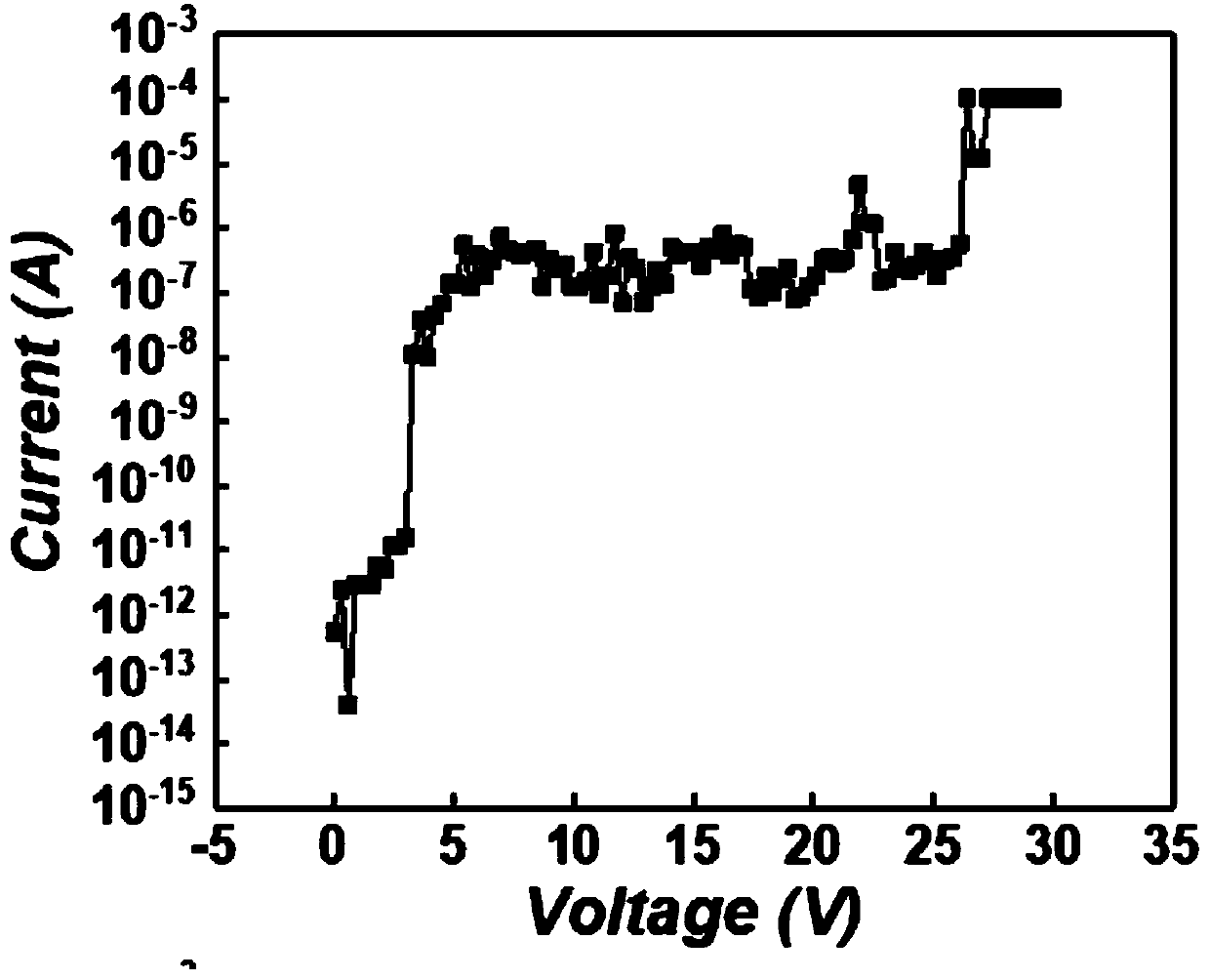

A gating device and transition layer technology, applied in the field of microelectronics, can solve the problems of small gating ratio, large leakage current, and low nonlinearity, and achieve the effects of integration, small leakage current, and high nonlinearity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

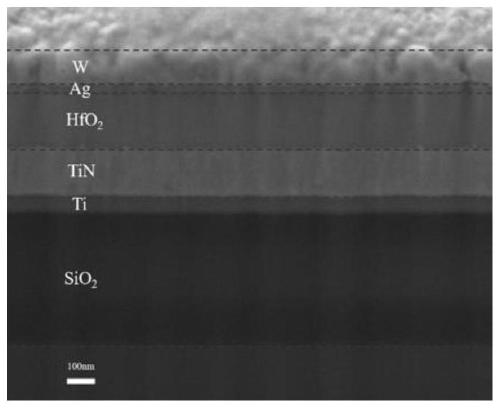

[0041] Such as figure 1 As shown, a silver intercalation gating device based on a hafnium oxide conversion layer in this embodiment, the gating device includes a bottom electrode layer, a conversion layer, a silver intercalation layer and a top electrode layer in sequence from bottom to top; wherein: the The material of the bottom electrode is titanium nitride, the material of the transition layer is hafnium oxide film material, and the material of the top electrode is metal tungsten; the thickness of the bottom electrode layer is 170nm, and the thickness of the transition layer is 200nm. The thickness of the silver intercalation layer is 20nm, the thickness of the top electrode layer is 120nm, the shape of each layer of the gating device is square, and the area of each layer is 0.36 μm 2 .

[0042] The silver intercalation gating device based on the hafnium oxide transition layer described above in this embodiment is prepared by the following method, which specifically inc...

Embodiment 2

[0054] A silver intercalation gating device based on a hafnium oxide conversion layer in this embodiment, the gating device sequentially includes a bottom electrode layer, a conversion layer, a silver intercalation layer and a top electrode layer from bottom to top; wherein: the bottom electrode The material is titanium nitride, the transition layer material is hafnium oxide thin film material, the top electrode material is metal tungsten; the thickness of the bottom electrode layer is 170nm, the thickness of the transition layer is 20nm, and the silver intercalation layer The thickness of the top electrode layer is 2nm, the thickness of the top electrode layer is 60nm, the shape of each layer of the gate device is square, and the area of each layer is 0.16 μm 2 .

[0055] The silver intercalation gating device based on the hafnium oxide transition layer described above in this embodiment is prepared by the following method, which specifically includes the following steps: ...

Embodiment 3

[0062] A silver intercalation gating device based on a hafnium oxide conversion layer in this embodiment, the gating device sequentially includes a bottom electrode layer, a conversion layer, a silver intercalation layer and a top electrode layer from bottom to top; wherein: the bottom electrode The material is titanium nitride, the transition layer material is hafnium oxide thin film material, the top electrode material is metal tungsten; the thickness of the bottom electrode layer is 170nm, the thickness of the transition layer is 250nm, and the silver intercalation layer The thickness of the top electrode layer is 40nm, the thickness of the top electrode layer is 150nm, the shape of each layer of the gate device is square, and the area of each layer is 1mm 2 .

[0063] The silver intercalation gating device based on the hafnium oxide transition layer described above in this embodiment is prepared by the following method, which specifically includes the following steps:

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com