Production method of coix seed extract

The technology of coix seed extract and production method, which is applied in the field of food processing, can solve the problems of long extraction process, high cost of solvent, and cumbersome extraction process steps of coix seed, so as to reduce the risk of slurry contaminating microorganisms and reduce production Time, saving process stagnation time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

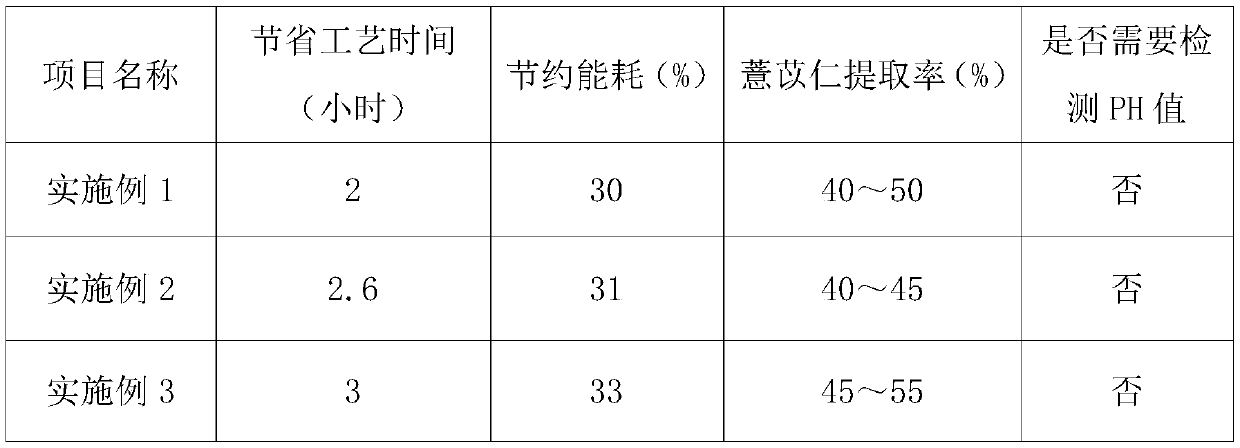

Embodiment 1

[0035]Take 20 kg of coix seed and undergo pretreatment of coix seed raw material, water extraction treatment, enzymatic hydrolysis treatment, concentration and drying treatment to obtain the coix seed extract. The pretreatment of Coix seed raw materials is that the Coix seed raw materials are first crushed and then roasted to obtain Coix seed powder. The Coix seed raw materials are crushed into Coix seed granules with a particle size of 10 mesh, and baked at a baking temperature of 100°C for 30 minutes. Water extraction process Add water according to the degree of coix seed crushing and combine the mass of coix seed particles with water at a ratio of 1:8, add 160 kg of water for extraction process. The water extraction temperature is controlled at 95° C., the water extraction time is 30 minutes, and the coix seed extract is obtained through extraction treatment. Coix seed extract, after water extraction, is in a gelatinized state, and then enters the next process, that is, enz...

Embodiment 2

[0037] Take 20 kg of coix seed and undergo pretreatment of coix seed raw material, water extraction treatment, enzymatic hydrolysis treatment, concentration and drying treatment to obtain the coix seed extract. The pre-treatment of coix seed raw materials is that the coix seed raw materials are first crushed and then roasted to obtain coix seed powder. The coix seed raw materials are crushed into coix seed granules with a particle size of 40 mesh, and baked at a baking temperature of 120°C for 30 minutes. Water extraction process Add water according to the degree of coix seed crushing, combine the mass of coix seed particles and water at a ratio of 1:10, add 200 kg of water, and perform extraction treatment. The water extraction temperature is controlled at 95° C., and the water extraction time is 40 minutes, and the coix seed extract is obtained through the extraction treatment. Coix seed extract, after water extraction, is in a gelatinized state, and then enters the next pro...

Embodiment 3

[0039] Take 20 kg of coix seed and undergo pretreatment of coix seed raw material, water extraction treatment, enzymatic hydrolysis treatment, concentration and drying treatment to obtain the coix seed extract. The pretreatment of Coix seed raw materials is that the Coix seed raw materials are crushed first and then roasted to obtain Coix seed powder. The Coix seed raw materials are crushed into Coix seed granules with a particle size of 60 mesh, and baked at a baking temperature of 100°C for 40 minutes. Water extraction process Add water according to the degree of coix seed crushing, combine the mass of coix seed particles and water according to the ratio of 1:12, add 240 kg of water, and carry out extraction process. The water extraction temperature is controlled at 100° C., the water extraction time is 60 minutes, and the coix seed extract is obtained through extraction treatment. Coix seed extract, after water extraction, is in a gelatinized state, and then enters the next...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com