Preparation method of negative electrode slurry

A negative electrode slurry and slurry technology, which is applied in the field of negative electrode slurry preparation, can solve the problems of easy agglomeration of slurry, influence on battery assembly and use, poor battery consistency, etc., and achieve convenient transfer and good Dispersion effect, effect of ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

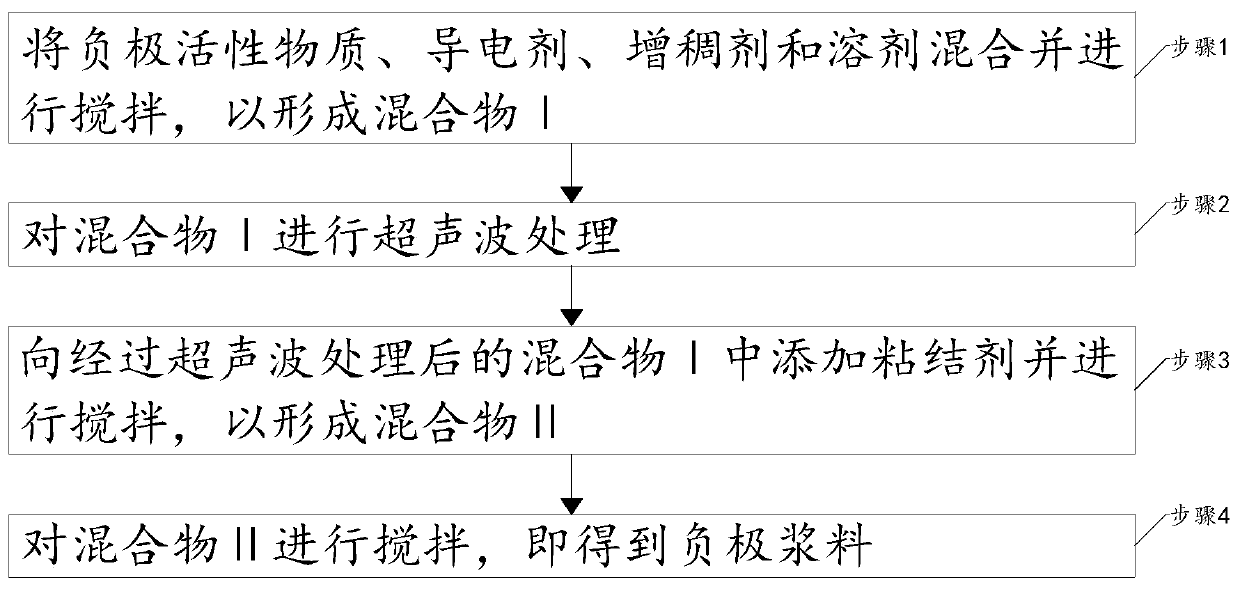

[0029] A preparation method of negative electrode slurry, comprising the following steps:

[0030] Step 1: mixing and stirring the negative electrode active material, the conductive agent, the thickener and the solvent to form a mixture I;

[0031] Step 11: Mix the negative electrode active material, conductive agent and thickener, and stir at a speed of 18-22rpm and disperse at a speed of 400-800rpm for 10-20min to form a mixture a; wherein, the negative electrode active material is natural graphite, Artificial graphite, soft carbon, hard carbon or silicon-carbon composite materials; the conductive agent is carbon nanotubes, graphene, acetylene black, Ketjen black or conductive carbon black. The thickener is sodium carboxymethyl cellulose.

[0032] Step 12: Add solvent to mixture a, and stir at a speed of 13-17rpm for 15-25min, then stir at a speed of 18-22rpm and disperse at a speed of 400-800rpm for 40-50min to form mixture b; the solvent is Deionized water.

[0033] Ste...

specific Embodiment 1

[0041] Step 1: Put 97 parts of graphite, 1 part of carbon nanotubes and 1 part of sodium carboxymethylcellulose into the stirring tank 1, mix and stir at a speed of 20 rpm and disperse at a speed of 500 rpm for 15 minutes to form a mixture a; Add 22 parts of deionized water to mixture a and stir at a speed of 15 rpm for 20 minutes, then stir at a speed of 20 rpm and disperse at a speed of 500 rpm for 45 minutes to form mixture b; slurry, and added 58 parts of deionized water to the mixture b again and first stirred at a speed of 15 rpm for 15 minutes, and then dispersed at a speed of 20 rpm and a speed of 700 rpm for 30 minutes to obtain a mixture I.

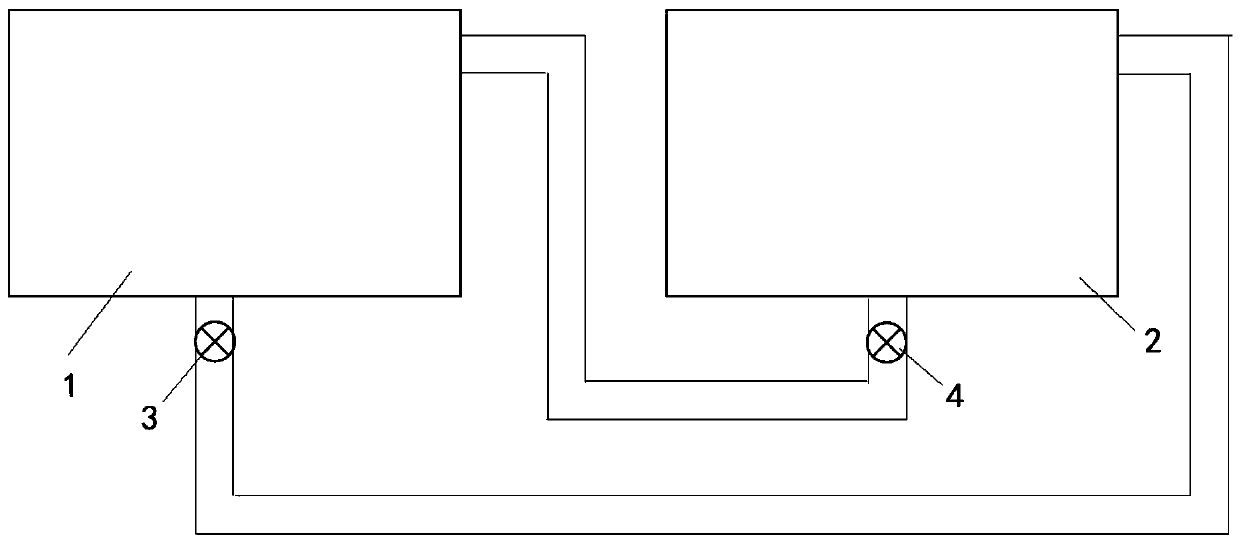

[0042] Step 2: Transport the mixture I in the stirring tank 1 to the ultrasonic tank 2 through the first diaphragm pump 3, and perform ultrasonic treatment for 30 minutes.

[0043] Step 3: Transport the ultrasonically treated mixture I in the ultrasonic tank 2 to the stirring tank 1 through the second diaphragm pump 4, and add s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com