Electroreduction carbon dioxide catalytic material as well as preparation and application thereof

A catalytic material, carbon dioxide technology, applied in the field of electrochemistry, can solve problems such as difficulty in industrial production, difficulty in catalyst preparation, low catalyst activity, etc., and achieve the effects of enhanced selectivity, improved catalytic stability, and simple synthesis methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Preparation of carbon material catalyst precursor: Take 16g of melamine and 8g of cysteine, put them in a ball mill tank, and then perform ball milling on a ball mill with a ball milling speed of 100rpm / min and a ball milling time of 2h, and fully mix to obtain a catalytic material precursor.

Embodiment 2

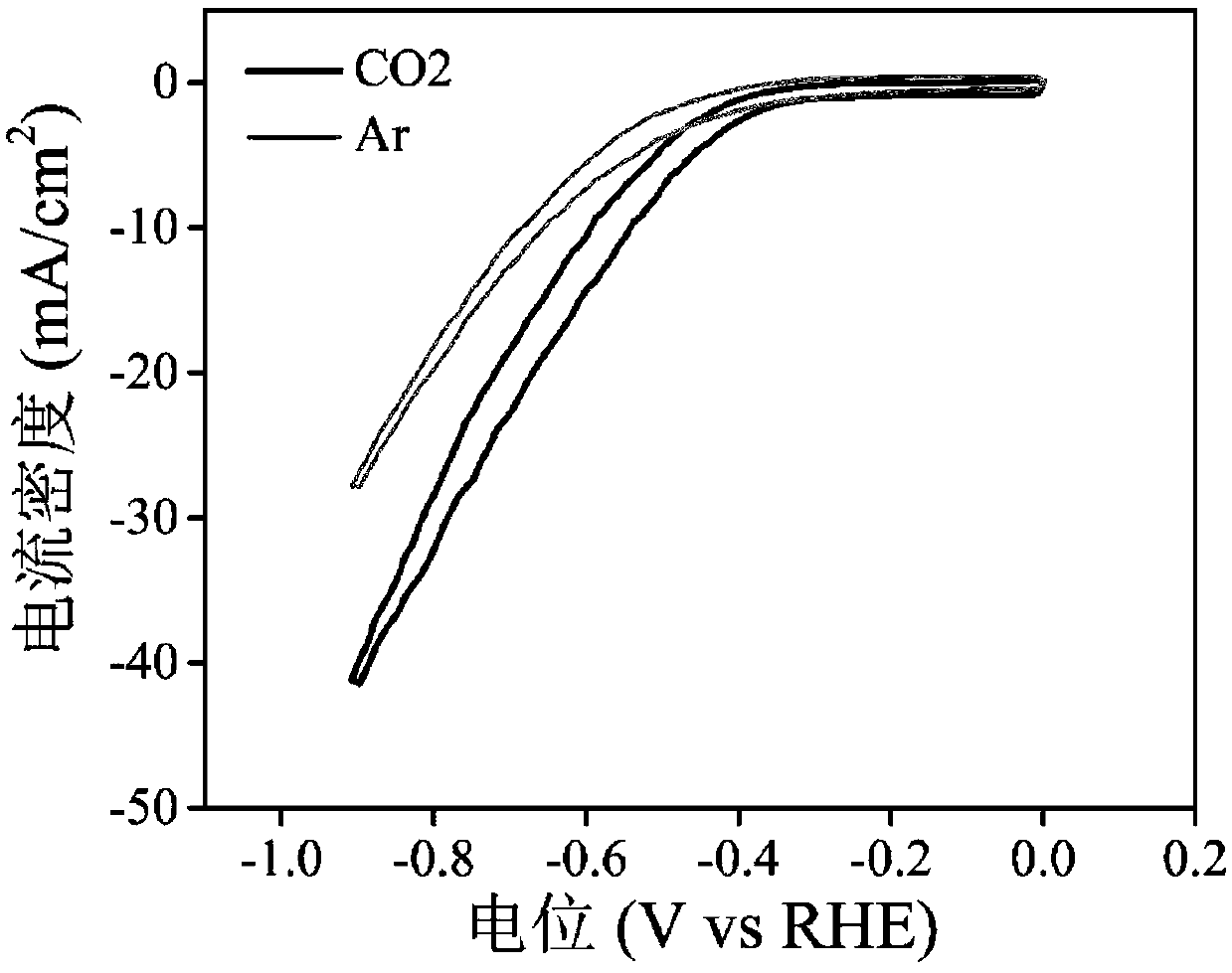

[0030] An electroreduction of CO 2 Catalyst material, comprises carbon material, and described carbon material is synthesized by high-temperature carbonization method, and its preparation method is: get 16g melamine, 16g cysteine, put in the ball mill tank, then carry out ball mill on ball mill, ball mill speed 100rpm / min, the ball milling time is 2h, and the catalyst material precursor is obtained through thorough mixing. The precursor was transferred into a zirconia boat, then placed in a tube furnace, fed with Ar gas at a flow rate of 25 mL / min, raised to 300 °C at a rate of 5 °C / min and maintained for 1 h, and then heated at a rate of 2.5 °C / min Raise the temperature to 600°C and keep it for 2h, then raise the temperature to 1000°C at a rate of 2°C / min and keep it for 2h, and finally cool naturally, and take out the carbon material, which is the electroreduction of CO 2 The catalytic material, called GM1.

Embodiment 3

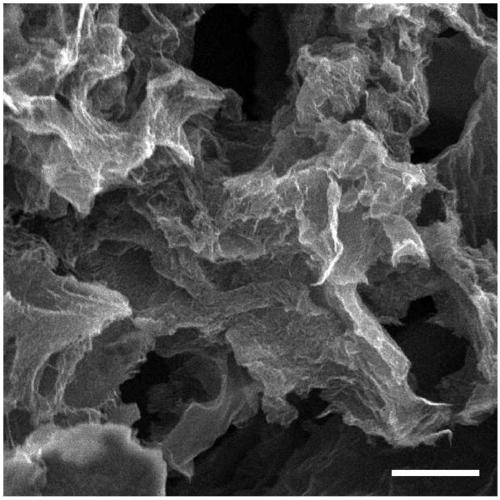

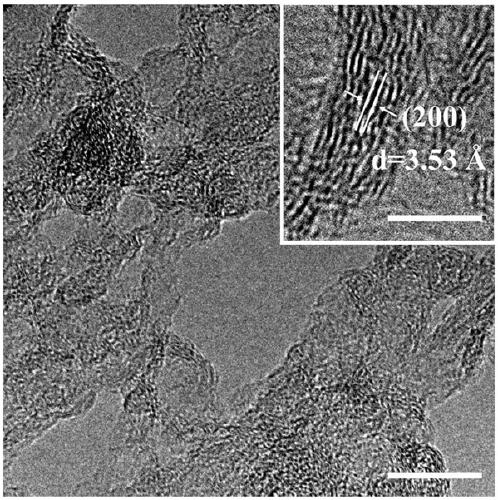

[0032] An electroreduction of CO 2 Catalyst material, comprises carbon material, and described carbon material is synthesized by high-temperature carbonization method, and its preparation method is: get 16g melamine, 8g cysteine, put in the ball mill pot, then carry out ball mill on ball mill, ball mill speed 100rpm / min, the ball milling time is 2h, and the catalyst material precursor is obtained through thorough mixing. The precursor was transferred into a zirconia boat, then placed in a tube furnace, fed with Ar gas at a flow rate of 25 mL / min, raised to 300 °C at a rate of 5 °C / min and maintained for 1 h, and then heated at a rate of 2.5 °C / min Raise the temperature to 600°C and keep it for 2h, then raise the temperature to 1000°C at a rate of 2°C / min and keep it for 2h, and finally cool naturally, and take out the carbon material, which is the electroreduction of CO 2 Catalytic material, called GM2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com