Efficient biological membrane synchronous nitrification and denitrification low-carbon sewage denitrification process

A technology of simultaneous nitrification and biofilm, applied in biological water/sewage treatment, sustainable biological treatment, special compound water treatment, etc. The effect of avoiding excessive organic matter content, reducing operation and maintenance and infrastructure costs, and stabilizing carbon source release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

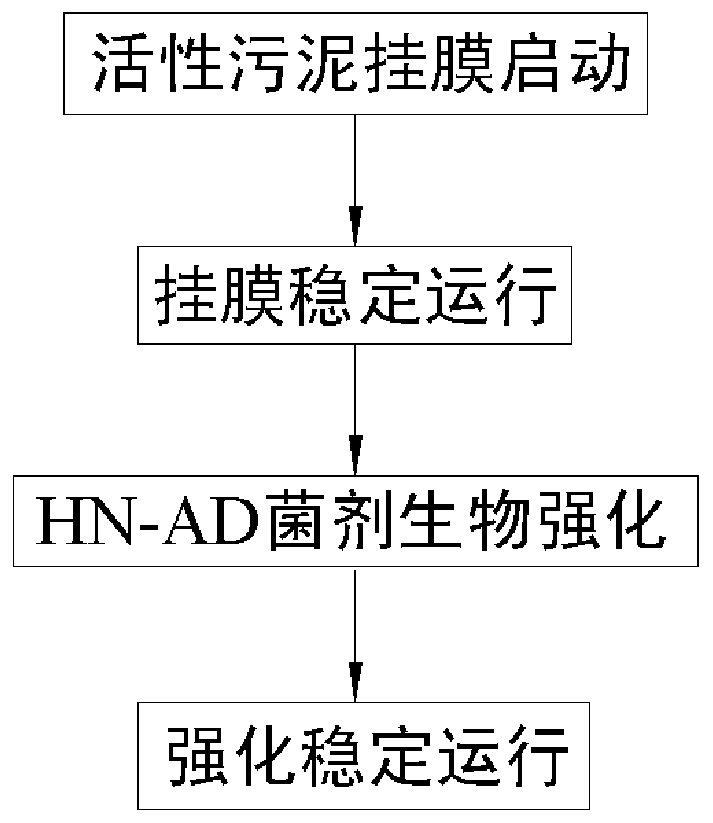

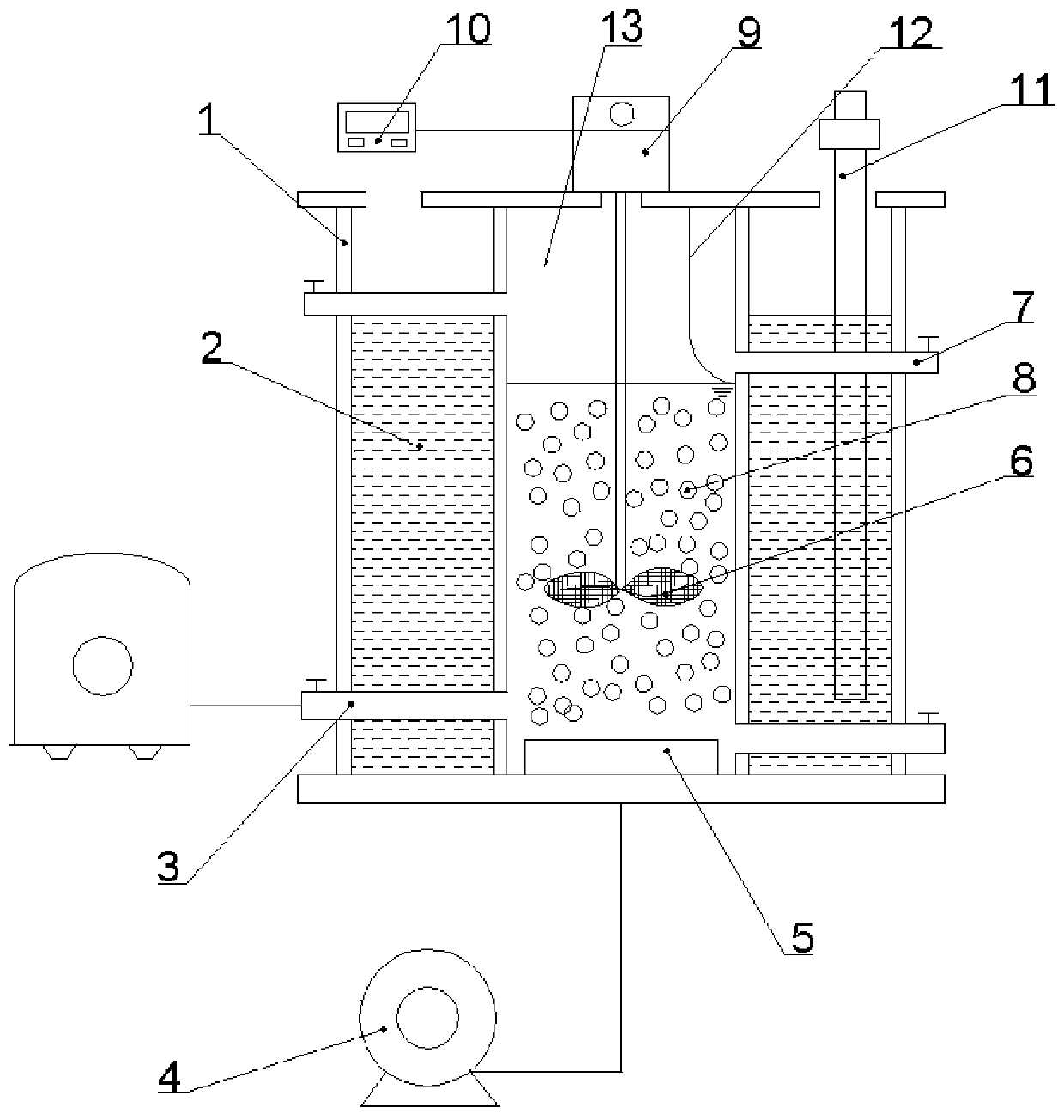

[0040] Embodiment 1, a kind of efficient biofilm synchronous nitrification and denitrification low-carbon sewage denitrification process, such as figure 1 , figure 2 As shown, the following steps are carried out in the moving bed biofilm reactor MBBR:

[0041] 1), Activated sludge film formation start

[0042] Add solid carbon source 8 fillers and activated sludge with a concentration of 3500-4500mg / L into the cavity of the MBBR. The solid carbon source 8 is a biodegradable material, which is one of PCL, PBS, PLA, PHAs, PHB, or a mixture of at least two of them. These biodegradable materials can provide stable carbon sources for microorganisms and can also be used as attachment carriers. The dosing volume of the solid carbon source 8 accounts for 20% to 50% of the effective volume of the MBBR cavity. Open the valves of the water inlet and outlet of the MBBR, so that the sewage flows into the cavity from the water inlet 3 at the lower end and the water outlet 7 at the upper...

Embodiment 2

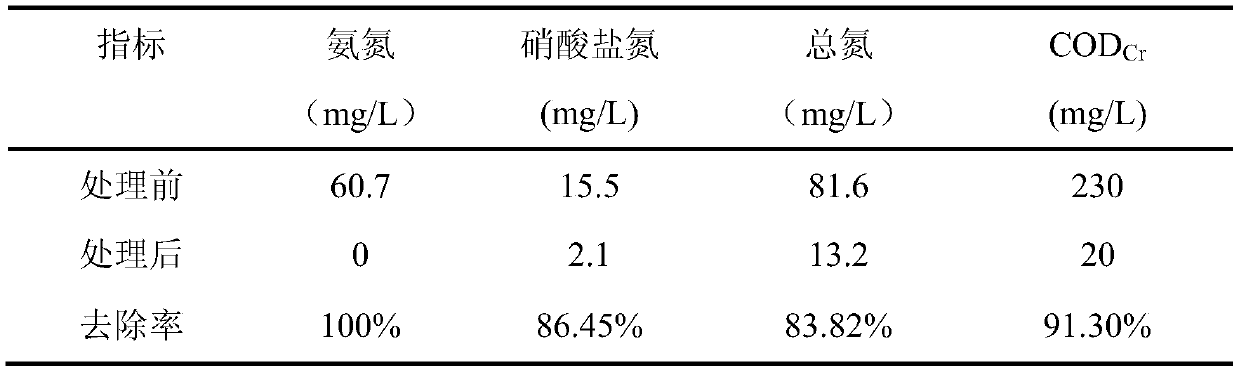

[0059] In step 1) of the process, PBS is selected as the solid carbon source 8, the DO of the liquid in the MBBR chamber 13 is selected and controlled at 3.5-5.0 mg / L, and the temperature of the MBBR constant temperature layer 2 is selected and controlled at a temperature of 30 ° C to 35 ° C. Step 3 ) to adjust the HRT to 13h. The water quality parameters of low-carbon urban domestic sewage flowing in from MBBR inlet 3 are: COD 250mg / L, NH 4 + -N 68.7mg / L, TN 92.6mg / L, nitrate nitrogen concentration 14.1mg / L, phosphate concentration 10.5mg / L. All the other steps remain consistent with Example 1, and the water quality changes before and after the process are as shown in Table 2:

[0060]

[0061] It can be seen from Table 1 and Table 2 that the high-efficiency biofilm synchronous nitrification and denitrification low-carbon sewage denitrification process can realize high-efficiency and stable deep denitrification of low-carbon sewage. It has good stress resistance, simple ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com