Aluminum-based binder for sintering high-alumina bricks and preparation method thereof

An aluminum-based binder and high-alumina brick technology, which is applied in the field of inorganic chemical industry, can solve the problems of increased silicon porosity, reduced strength, and reduced heat and corrosion resistance of products, and achieves improved compressive strength at room temperature and softening under load Increased temperature and improved thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

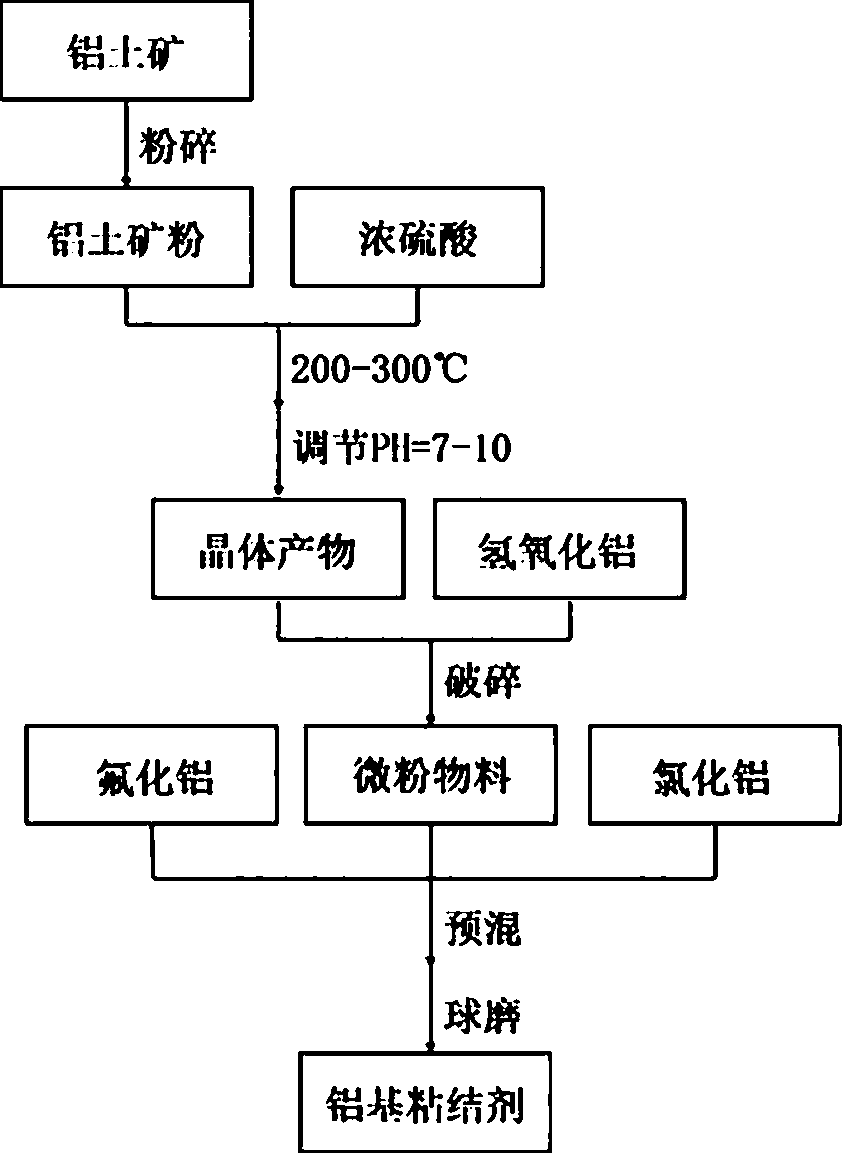

Method used

Image

Examples

Embodiment 1

[0019] Crush 3.5kg of bauxite to a particle size of 100-200 mesh, place it in a reaction kettle at 300°C and react with 1.5kg of concentrated sulfuric acid for 30 minutes, let it stand still, add concentrated sulfuric acid to the supernatant until pH = 8, and place it at 115°C Cool down and crystallize to obtain a crystal product; put the above crystal product and 5.7kg of aluminum hydroxide in a jaw crusher, and crush it into a fine powder material with a particle size of 100-200 mesh; add 0.2 kg of aluminum fluoride to the above fine powder material and 0.1kg of aluminum chloride, and put them together in an aluminum grinding wet mill for premixing for 20 minutes to obtain a premixed material; put the premixed material in a ball mill and ball mill for 3 hours to obtain a sintered high-alumina brick for aluminum-based bonding agent.

[0020] Using the aluminum-based binder to prepare high-alumina refractory bricks, the steps are as follows: 1) 45 parts of bauxite aggregates w...

Embodiment 2

[0023] Crush 4.0kg of bauxite to a particle size of 100-200 mesh, place it in a 300°C reactor and react with 1.0kg of concentrated sulfuric acid for 30min, let it stand, add concentrated sulfuric acid dropwise to the supernatant to pH = 8, and place it at 115°C Cool down and crystallize to obtain a crystal product; put the above crystal product and 5.8kg of aluminum hydroxide in a jaw crusher, and crush it into a fine powder material with a particle size of 100-200 mesh; add 0.1 kg of aluminum fluoride to the above fine powder material and 0.1kg of aluminum chloride, and put them together in an aluminum grinding wet mill for premixing for 20 minutes to obtain a premixed material; put the premixed material in a ball mill and ball mill for 3 hours to obtain a sintered high-alumina brick for aluminum-based bonding agent.

[0024] The aluminum-based binder is used to prepare high-alumina refractory bricks, and the steps are the same as in Example 1.

[0025] The density of high a...

Embodiment 3

[0027] Crush 3.9kg of bauxite to a particle size of 100-200 mesh, place it in a 300°C reactor and react with 1.1kg of concentrated sulfuric acid for 30 minutes, let it stand, add concentrated sulfuric acid dropwise to the supernatant to pH = 8, and place it at 115°C Cool down and crystallize to obtain a crystal product; put the above crystal product and 5.6kg of aluminum hydroxide in a jaw crusher, and crush it into a fine powder material with a particle size of 100-200mm; add 0.2kg of aluminum fluoride to the above fine powder material and 0.2kg of aluminum chloride, and put them together in an aluminum grinding wet mill for premixing for 20 minutes to obtain a premixed material; put the premixed material in a ball mill and ball mill for 3 hours to obtain a sintered high alumina brick bonded with an aluminum matrix agent.

[0028] The aluminum-based binder is used to prepare high-alumina refractory bricks, and the steps are the same as in Example 1.

[0029] The density of h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com