Water-based transparent corrosion-resistant coating steel rail and preparation method thereof

A transparent, steel rail technology, applied in the field of rail transit, can solve the problems of low economic cost of corrosion protection technology, few reports on coatings, etc., and achieve the effect of reducing production cost and labor intensity, no impact on mechanical properties, and low curing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] Specifically, the invention provides a method for preparing a water-based transparent corrosion-resistant coating rail, the method comprising the steps of:

[0023] a. In terms of mass percentage, 60-70% polyvinyl acrylic acid copolymer emulsion, 0.8-1% anionic water-soluble copolymer, 1-3% nano-zinc phosphate, 1-3% phytic acid, 1-3% Mix potassium ferricyanide with 20%~36% water, ultrasonically disperse for 20~30min, and use AMP-95 to adjust the pH value to 5.5~6.5 to obtain the coating;

[0024] b. Use compressed air to remove floating dust on the surface of the rail, and evenly coat the paint on the rail head, rail waist and rail bottom surface of the rail, and cure it at room temperature for 20-30 minutes to obtain a water-based transparent corrosion-resistant coating rail.

[0025] In step a of the present invention, in terms of mass percentage, 60-70% polyvinyl acrylic acid copolymer emulsion, 0.8-1% anionic water-soluble copolymer, 1-3% nano-zinc phosphate, 1-3% p...

Embodiment 1

[0029] Preparation of water-based transparent corrosion-resistant coating steel rail by adopting the method of the present invention

[0030] a. In terms of mass percentage, mix 60% polyvinyl acrylic acid copolymer emulsion, 1% HT-5020 dispersant, 1% nano-zinc phosphate, 1% phytic acid, 1% potassium ferrocyanide and 36% water, Ultrasonic dispersion for 30 minutes, using AMP-95 to adjust the pH value to 6.0 to obtain the coating;

[0031] b. Use compressed air to remove floating dust on the surface of the rail, and evenly coat the coating on the rail head, rail waist and rail bottom surface of the rail. After curing for 30 minutes at room temperature, lightly touch the coating surface with your fingers. No coating sticks to your fingers. The thickness of the rail surface coating was determined to be 30um.

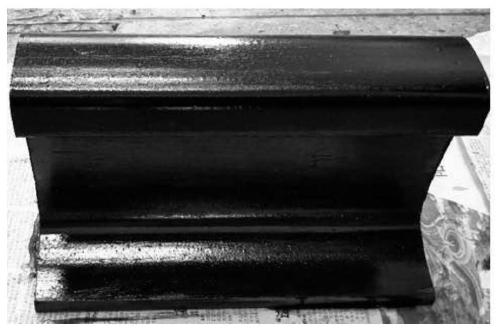

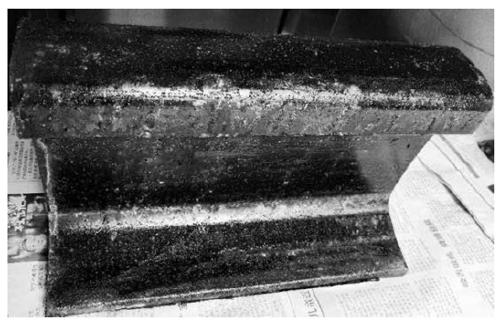

[0032] The surface morphology of the coating is as figure 1 shown. After hard drying, test the corrosion resistance of the above samples according to GB / T1771-1991 Determ...

Embodiment 2

[0034] a. In terms of mass percentage, mix 70% polyvinyl acrylic acid copolymer emulsion, 1% HT-5020 dispersant, 1% nano-zinc phosphate, 1% phytic acid, 1% potassium ferrocyanide and 26% water, Ultrasonic dispersion for 30 minutes, using AMP-95 to adjust the pH value to 5.5 to obtain the coating;

[0035] b. Use compressed air to remove floating dust on the surface of the rail, and evenly coat the coating on the rail head, rail waist and rail bottom surface of the rail. After curing for 25 minutes at room temperature, lightly touch the coating surface with your fingers. No coating sticks to your fingers. The thickness of the rail surface coating was determined to be 45um.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com