Water-based acrylic acid energy-storage luminescent coating and preparation method thereof

A water-based acrylic, energy storage and luminous technology, applied in the field of coatings, can solve the problems of poor construction performance and high consistency, and achieve the effects of low VOC content, high luminous brightness and high luminous intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0077] The preparation method of water-based acrylic acid energy storage luminous paint, comprises the following steps:

[0078] Mix water, dispersant, wetting agent and luminescent powder pretreatment agent, stir evenly, add rare earth doped aluminate type long-lasting luminous powder and disperse at high speed, grind to obtain color paste; then add thickener to the color paste agent, stirred evenly and then filtered to obtain the finished product.

[0079] Wherein, grinding is carried out using a grinder.

[0080] The construction technology and detection method of the water-based luminous paint involved in the present invention are as follows:

[0081] The luminous paint can be applied by brushing or spraying, stir well before use, and adjust the viscosity with water. Only when the paint film thickness reaches more than 100μm and the film thickness is relatively uniform can a paint film with higher brightness be formed, for this reason, it generally needs to be sprayed 2-...

Embodiment 1-5

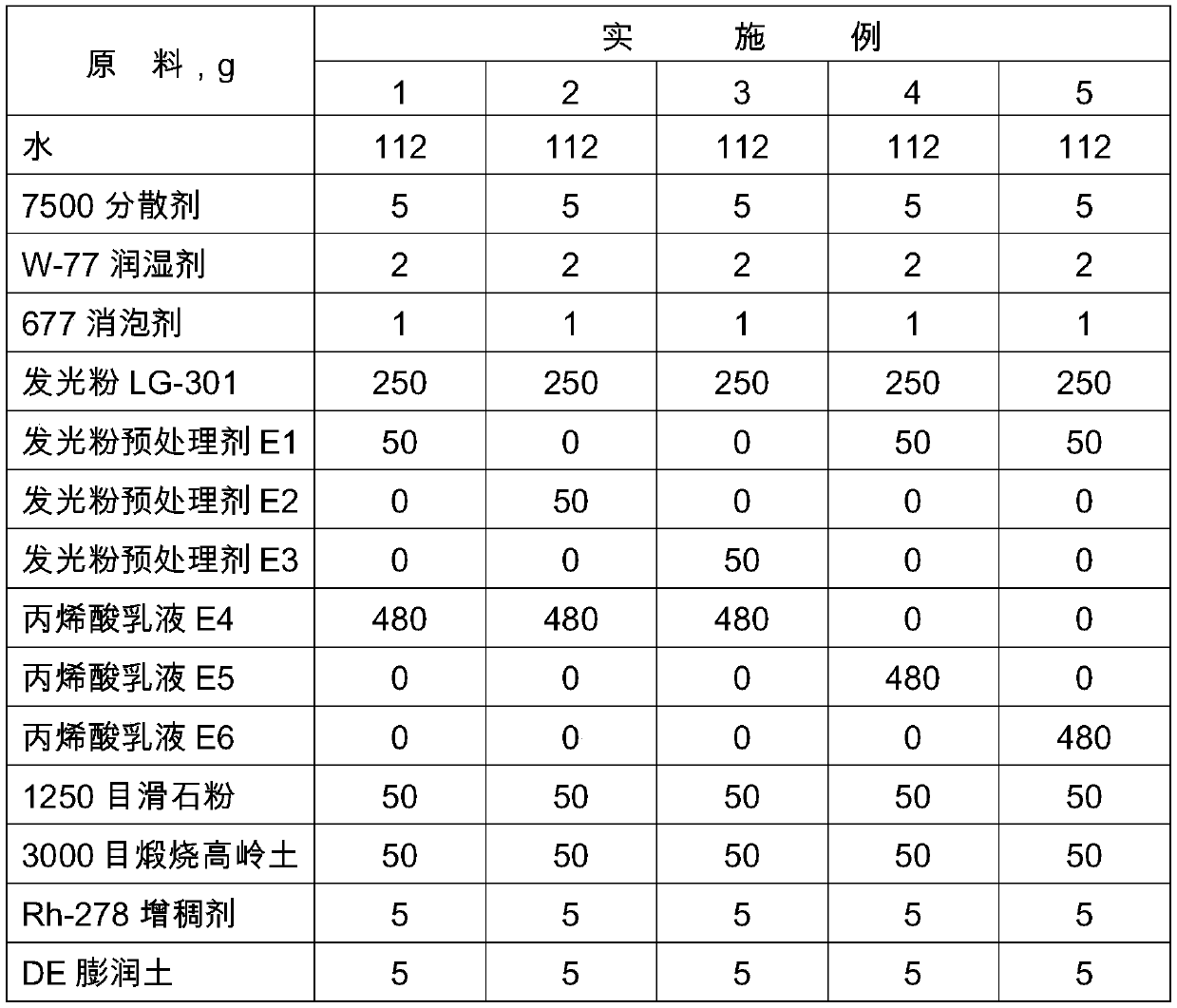

[0085] Examples 1-5 relate to a water-based acrylic energy-storing luminous paint, and the specific formula of the paint is shown in Table 1.

[0086] Table 1. The formulations of the luminous coatings of each embodiment

[0087]

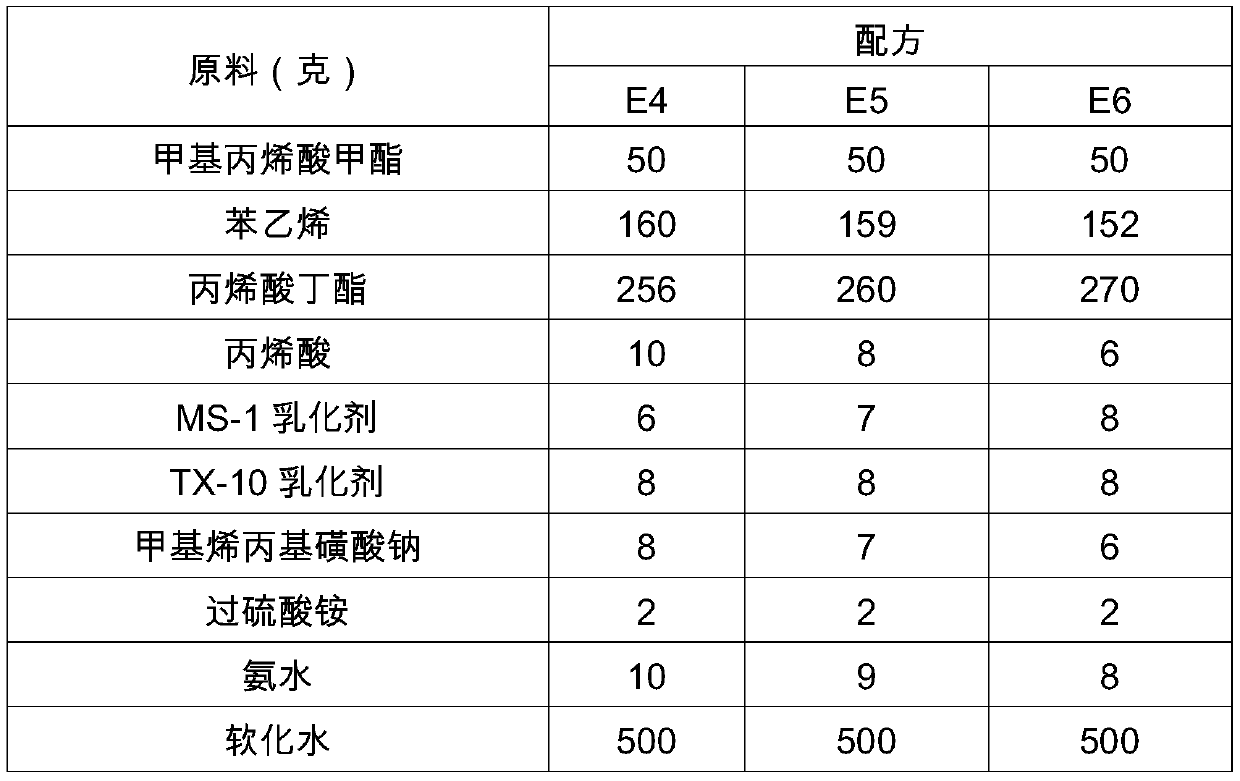

[0088] Among them, the specific formulations of the luminescent powder pretreatment agents E1-E3 in Table 1 are shown in Table 2, and the specific formulations of the acrylic emulsion E4-E6 are shown in Table 3.

[0089] Table 2. Formulas of luminescent powder pretreatment agents in each embodiment

[0090]

[0091] Table 3. Acrylic emulsion formula of each embodiment

[0092]

[0093] Waterborne acrylic paints are formulated as follows:

[0094] S1. Preparation of luminescent powder pretreatment: ①Add propylene glycol methyl ether and dipropylene glycol methyl ether into a reaction vessel equipped with a stirrer, thermometer, condenser, and dropping tank, start stirring, add epoxy resin, and heat to 80- 90°C, keep stirring until the epo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com