Degradable anti-infection lithiasis-preventing Fe-Cu series alloy applicable to urinary implant material

An implant material and anti-infection technology, applied in medical science, prosthesis, etc., can solve the problems of increasing retrograde infection, disturbing the normal operation system, and causing patients' physiological pain and heavy economic burden, and achieves strong antibacterial and anti-calculus functions and mechanical properties Large adjustment range, prevent stone formation and growth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

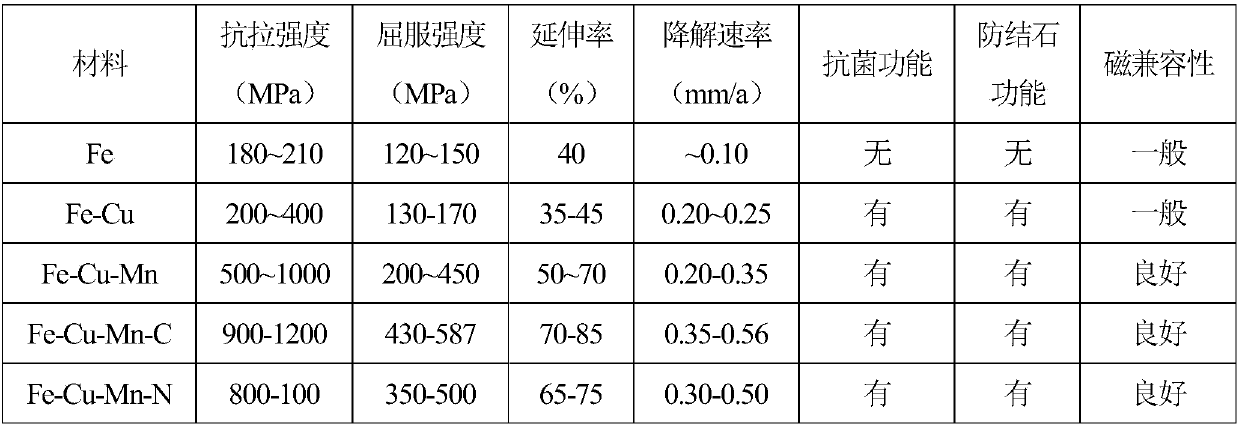

[0039] In this embodiment, the composition of the Fe-0.5Cu alloy is: 0.5% Cu, and the balance is Fe.

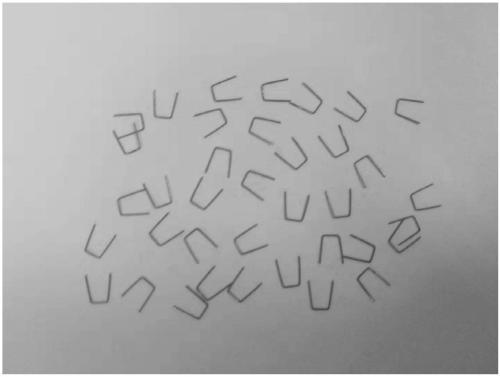

[0040] Preparation method: The above-mentioned composition alloy is made into an ingot by vacuum induction melting, and after being kept at 1000°C for 2 hours, it is forged into a rod of Φ20mm, processed into a rod of Φ6mm~10mm by extrusion or swaging, and processed into a rod of Φ0. 2 ~ 0.6mm wire, prepared into staples (YY / T 0245-2008). During the drawing process, supplemented by heat treatment, the treatment process is 1000 ° C under vacuum atmosphere for 1 hour, water quenching and cooling to room temperature.

[0041] Tensile properties (GB / T 228-2002): The tensile strength is 200MPa, the yield strength is 130MPa, and the elongation is 45%.

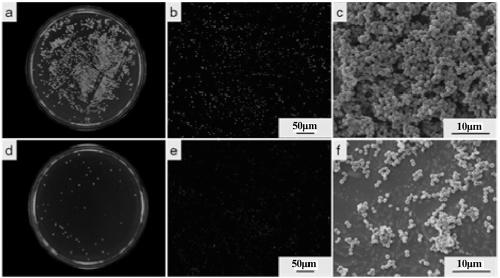

[0042] Antibacterial properties (GB / T 2591): Sterilization rate for Staphylococcus aureus: 98%; Sterilization rate for Mirabilis proteus: 95%.

[0043] Anti-stone performance: stone rate <5%.

[0044] Degradation rate (artificial...

Embodiment 2

[0047] In this embodiment, the composition of the Fe-1Cu-25Mn alloy is: 1% Cu, 25% Mn, and the balance is Fe.

[0048] Preparation method: The above-mentioned composition alloy is made into an ingot by vacuum induction melting, and after being kept at 1000°C for 2 hours, it is forged into a rod of Φ20mm, processed into a rod of Φ6mm~10mm by extrusion or swaging, and processed into a rod of Φ0. 2-1mm wire, prepared into staples (YY / T 0245-2008). During the drawing process, supplemented by heat treatment, the treatment process is 1000 ° C under vacuum atmosphere for 1 hour, then water quenching.

[0049] Tensile properties (GB / T 228-2002): The tensile strength is 820MPa, the yield strength is 260MPa, and the elongation is 65%.

[0050] Antibacterial properties (GB / T 2591): Sterilization rate for Staphylococcus aureus: 99%; Sterilization rate for Mirabilis proteus: 96%.

[0051] Anti-stone performance: stone rate <5%.

[0052] Degradation rate (artificial urine, soaked for 30 ...

Embodiment 3

[0055] In this embodiment, the composition of the Fe-2Cu-20Mn-1C alloy is: 2% Cu, 20% Mn, 1% C, and the balance is Fe.

[0056] Preparation method: The above composition alloy is made into an ingot by vacuum induction melting, and after being kept at 980°C for 3 hours, it is forged into a rod of Φ20mm, processed into a rod of Φ6mm~10mm by extrusion or swaging, and processed into a rod of Φ0. 2-1mm wire, prepared into staples (YY / T 0245-2008). During the drawing process, supplemented by heat treatment, the treatment process is 950 ° C for 1.5 hours in a vacuum atmosphere, and then water quenching.

[0057] Tensile properties (GB / T 228-2002): The tensile strength is 1050MPa, the yield strength is 360MPa, and the elongation is 70%.

[0058] Antibacterial properties (GB / T 2591): Sterilization rate for Staphylococcus aureus: 99%; Sterilization rate for Mirabilis proteus: 99%.

[0059] Anti-stone performance: stone rate <5%.

[0060] Degradation rate (artificial urine, soaked for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com