Heat supply unit total heat recovery system with nearly zero energy consumption and heat supply control method thereof

A heating unit and total heat recovery technology, applied in heating systems, hot water central heating systems, heating methods, etc., can solve problems such as waste of water, unsatisfactory central heating systems, and atmospheric environmental pollution, so as to reduce investment and Effects of operating costs, improving heat transfer capacity, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

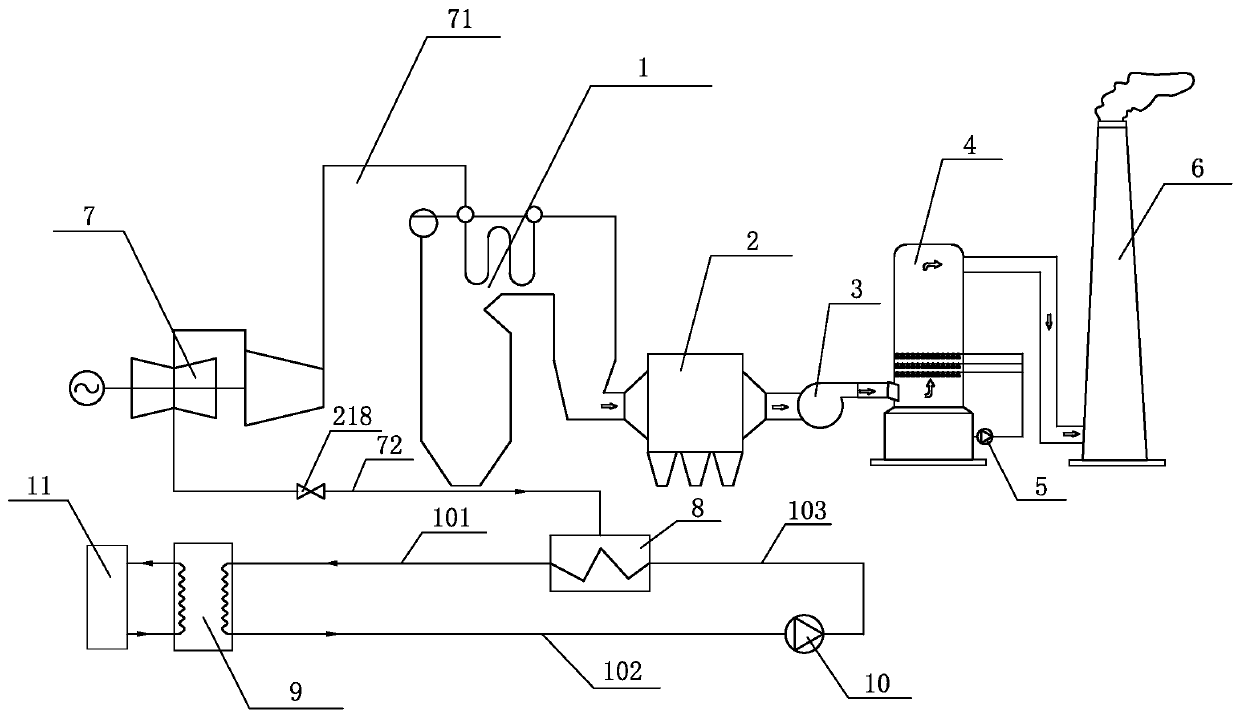

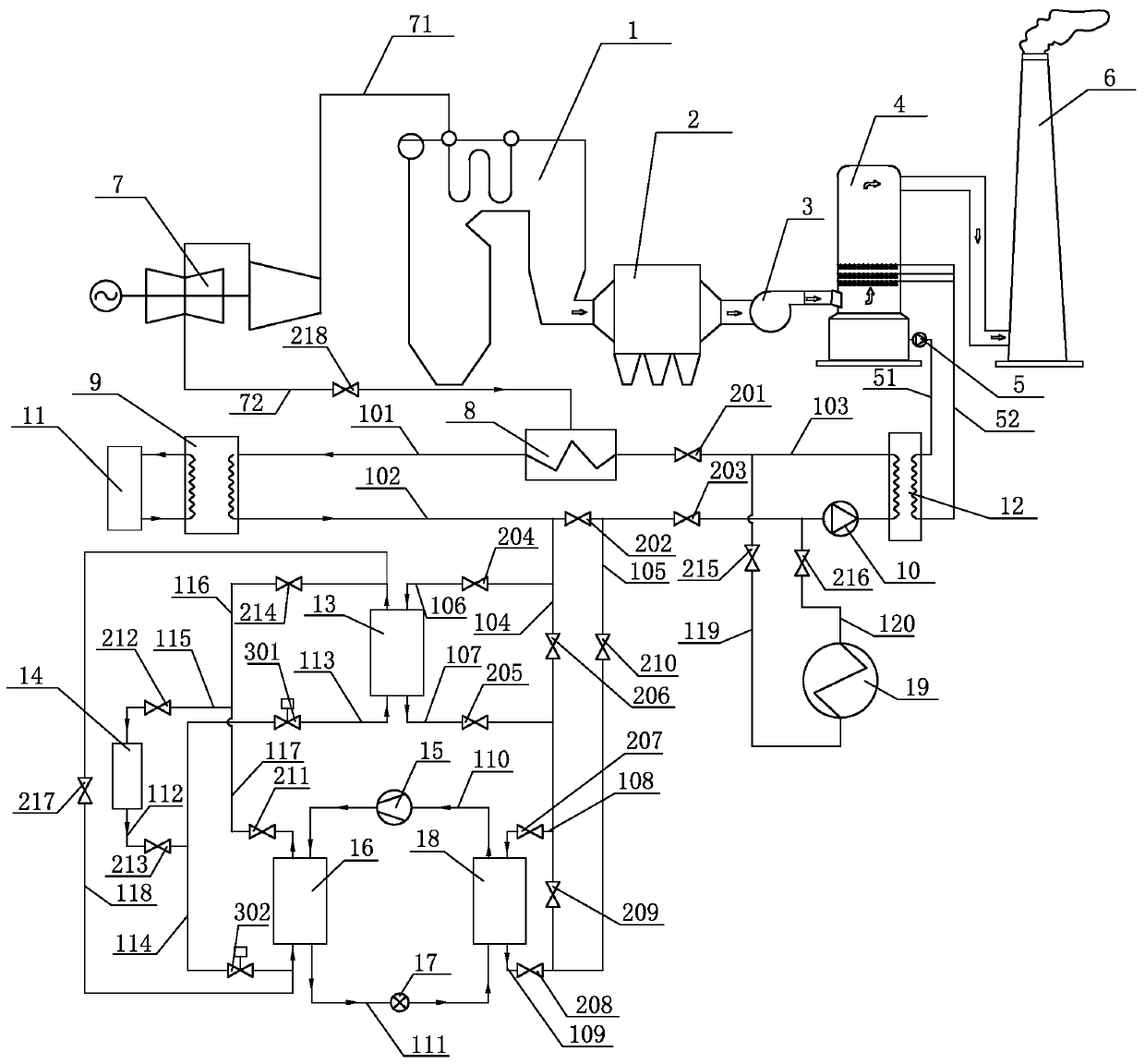

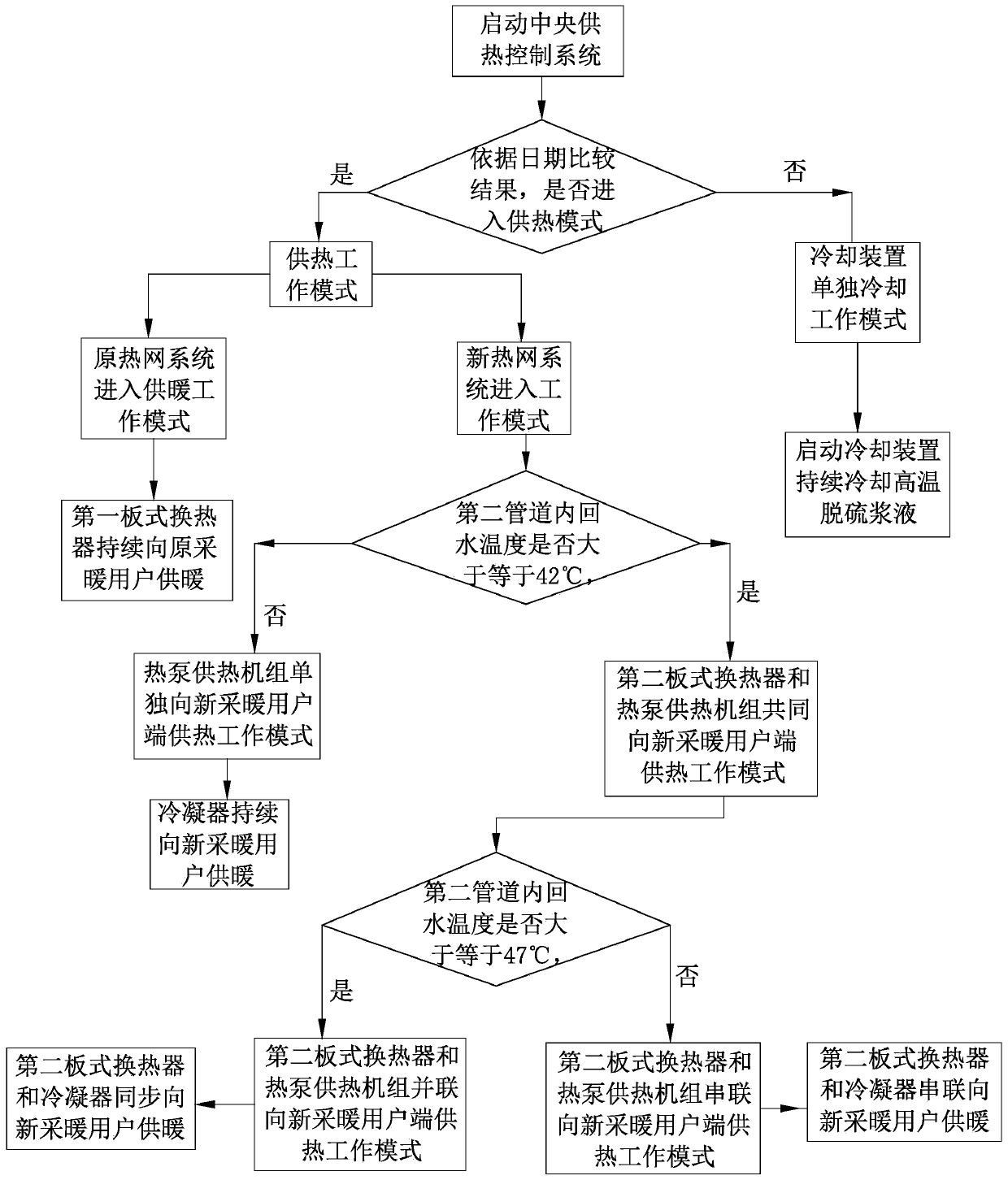

[0024] Below will combine specific embodiment and appended Figure 1-3 , clearly and completely describe the technical solutions in the embodiments of the present invention, obviously, the described embodiments are only some preferred embodiments of the present invention, not all the embodiments. Those skilled in the art can make similar modifications without departing from the connotation of the present invention, so the present invention is not limited by the specific embodiments disclosed below.

[0025] The present invention provides a nearly zero energy consumption heating unit total heat recovery system (such as figure 2 shown), including heat source system, heat network system and central heating control system, said heat source system includes boiler 1, dust remover 2, induced draft fan 3, desulfurization tower 4, chimney 6 and steam turbine 7, said boiler 1, dust collector The device 2, the induced draft fan 3, the desulfurization tower 4 and the chimney 6 are respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com