Preparation method and application of PVC-carbon paste modified electrode for lead ion detection

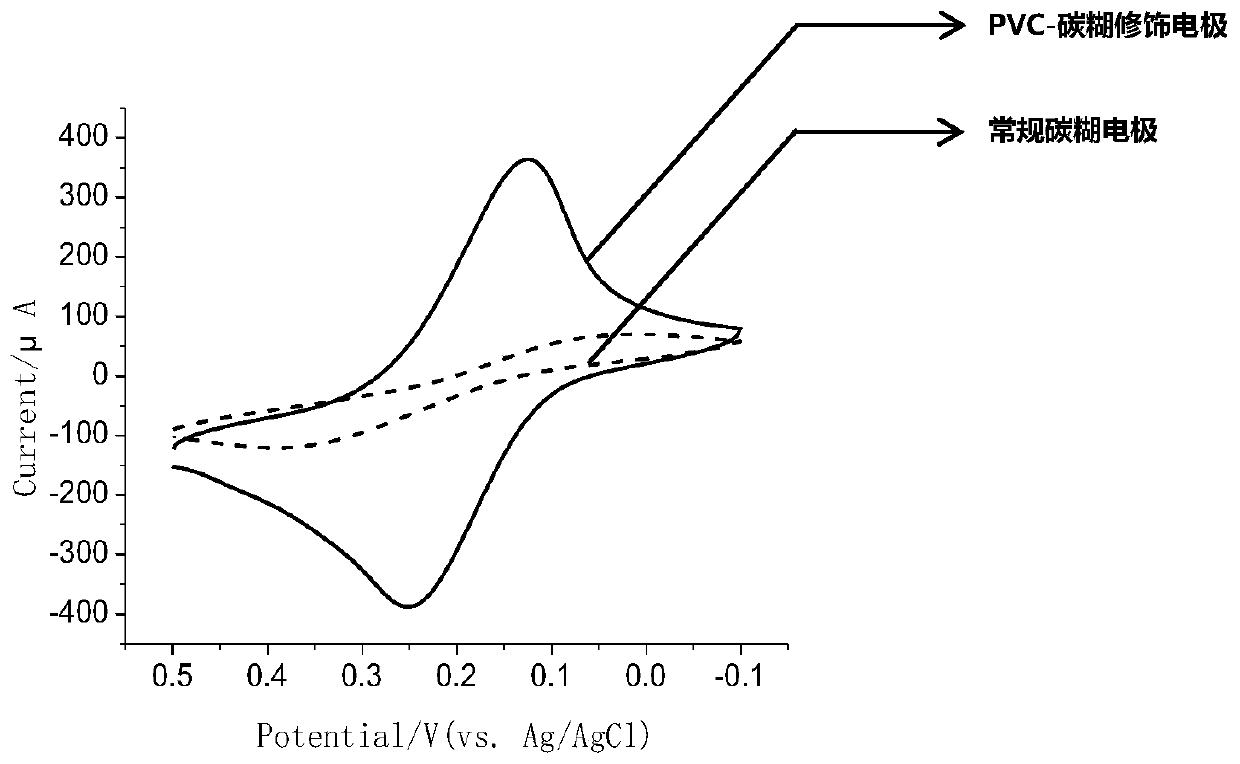

A technology for modifying electrodes and lead ions, applied in the field of electrochemical detection, can solve problems such as the existence of mercury and mercury environmental toxicity that cannot be excluded, and achieve the effects of excellent mechanical strength, good reproducibility and low signal-to-noise ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Preparation of PVC-carbon paste modified electrode:

[0033] (1) Weigh 0.2000g of PVC powder and dissolve it in an appropriate amount of tetrahydrofuran, then add 3.0000g of graphite powder and mix evenly. , and then polished smooth on weighing paper, rinsed the surface of the electrode with distilled water, and dried it at room temperature for later use.

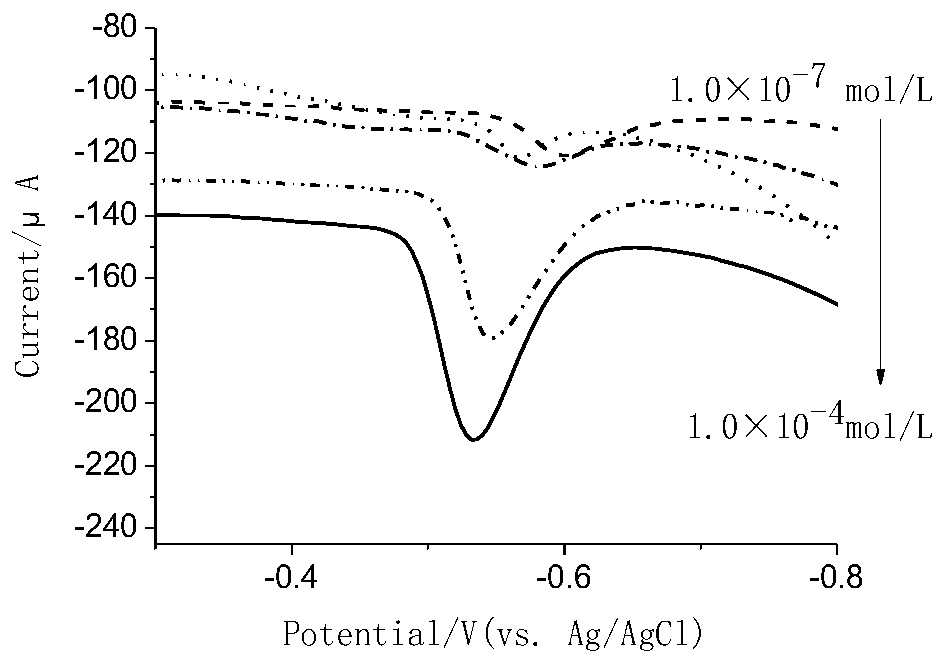

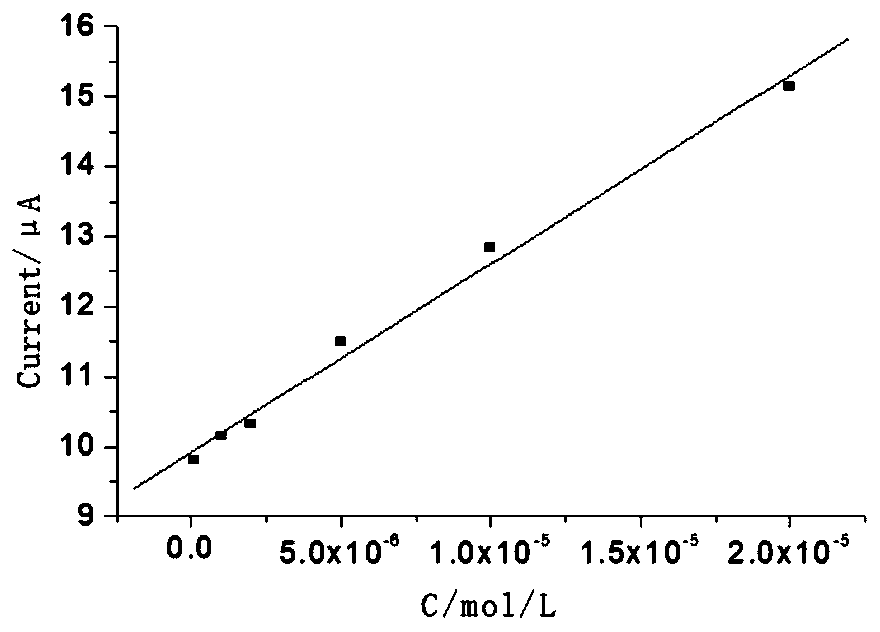

[0034] (2) Put the prepared PVC-carbon paste modified electrode into a potassium nitrate solution with a pH of 11.0 to react for 10 minutes, carry out enrichment treatment, take it out and wash it, place it in a 0.15M nitric acid solution, and electrolyze it at a reduction potential of -1.0V For 60 seconds, the lead ion concentration was tested by differential pulse anodic stripping voltammetry.

Embodiment 2

[0036] Preparation of PVC-carbon paste modified electrode:

[0037] (1) Weigh 0.2000g of PVC powder and dissolve it in an appropriate amount of tetrahydrofuran, then add 2.0000g of graphite powder and mix evenly. , and then polished smooth on weighing paper, rinsed the surface of the electrode with distilled water, and dried it at room temperature for later use.

[0038](2) Put the prepared PVC-carbon paste modified electrode into a potassium nitrate solution with a pH of 11.0 to react for 10 minutes, carry out enrichment treatment, take it out and wash it, place it in a 0.15M nitric acid solution, and electrolyze it at a reduction potential of -1.0V For 60 seconds, the lead ion concentration was tested by differential pulse anodic stripping voltammetry.

Embodiment 3

[0040] Preparation of PVC-carbon paste modified electrode:

[0041] (1) Weigh 0.2000g of PVC powder and dissolve it in an appropriate amount of tetrahydrofuran, then add 2.4000g of graphite powder and mix evenly. , and then polished smooth on weighing paper, rinsed the surface of the electrode with distilled water, and dried it at room temperature for later use.

[0042] (2) Put the prepared PVC-carbon paste modified electrode into a potassium nitrate solution with a pH of 11.0 to react for 10 minutes, carry out enrichment treatment, take it out and wash it, place it in a 0.15M nitric acid solution, and electrolyze it at a reduction potential of -1.0V For 60 seconds, the lead ion concentration was tested by differential pulse anodic stripping voltammetry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com