Electrochromic nonmetallic salt electrolyte composite material, preparation method and application

An electrochromic and composite material technology, applied in nonlinear optics, optics, instruments, etc., can solve the problems of complex structure, poor performance and poor stability of electrochromic devices, and achieve rich color types, simple structure, and safety. high sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A preparation method of an electrochromic non-metal salt electrolyte composite material, comprising the following steps:

[0026] Step i, preparing tungsten oxide sol;

[0027] According to the present invention, the preparation of the tungsten oxide sol is not particularly limited, it can be prepared by a known preparation method in the art, preferably by ion exchange, and the specific method is preferably:

[0028] Activate the ion exchange resin before use, specifically: put the resin into a chromatography column, pass through the resin layer with hydrochloric acid with a concentration of 3.0M at a flow rate of 3M / h, and then use a volume of 1.5-2.5% of the resin volume. times, concentration of 2.0-2.5M sulfuric acid soaked for more than 3 hours, and then 0.5M concentration of Na 2 WO 4 The aqueous solution flows through the ion exchange resin to obtain tungsten oxide sol.

[0029] Step ii, preparing amino or substituted amino-modified carbon nanodots;

[0030] A...

Embodiment 1

[0038] (1) Tungsten oxide sol is prepared by ion exchange. The main materials and reagents are: ion exchange resin, sodium tungstate hydrate (Na 2 WO 4 ·2H2O), deionized water (resistivity 18.2MΩ·cm), absolute ethanol (C2H5OH).

[0039] Activate the ion exchange resin before use, specifically: put the resin into a chromatographic column, pass through the resin layer with hydrochloric acid with a concentration of 3.0M at a flow rate of 3M / h, and then use a volume of 1.5-2.5% of the resin volume. times, concentration of 2.0-2.5M sulfuric acid soaked for more than 3 hours, and then 0.5M concentration of Na 2 WO 4 The aqueous solution flows through the ion exchange resin to obtain tungsten oxide sol.

[0040] (2) Carbon nanodots are synthesized by microwave method, and the materials used include: citric acid (C 6 h 8 o 7 ·H 2 O), urea (CH 4 N 2 O), deionized water (resistivity 18.2MΩ·cm).

[0041] Specific preparation method: put 3g of citric acid and 3g of urea in 10mL ...

Embodiment 2

[0049] Prepare the electrochromic non-metallic salt electrolyte composite material in the same manner as in Example 1, the difference is that in WO 3 The volume ratio of sol and ethanol is 5:1, which is recorded as device-2.

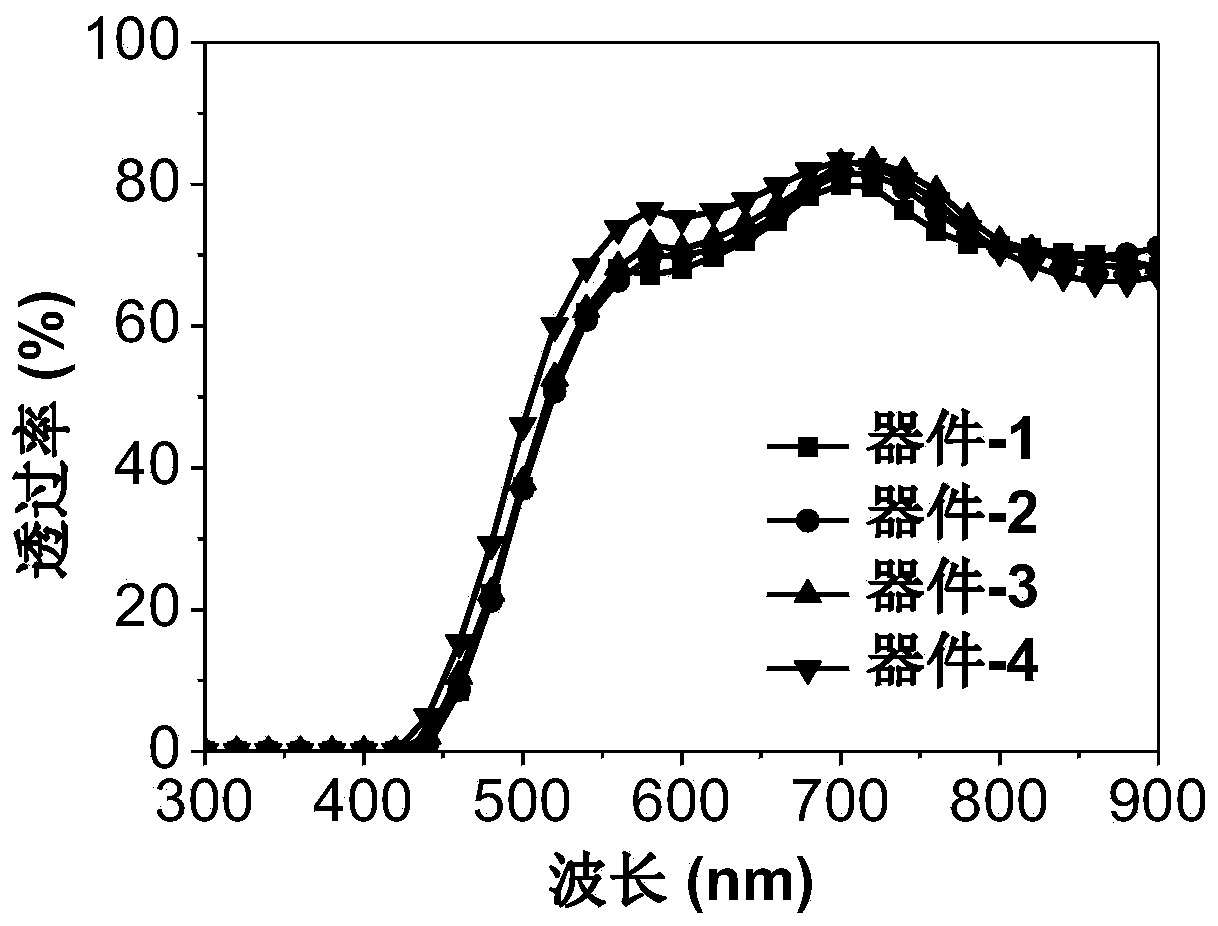

[0050] After characterization, the optical contrast ratio of the electrochromic device obtained in the present embodiment 2 is slightly lower than that in embodiment 1, which is 38%, and the coloring and fading response times are shortened, which are respectively 15s and 78s. The transmittance curve is as figure 1 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com