A Design Method of Tunnel Blasting Parameters Based on Digital Electronic Detonator Initiation

A technology of digital electronic detonators and tunnels, which is applied in blasting, design optimization/simulation, etc., can solve the problems of common detonators with large delay errors, lack of universal applicability, and large dispersion of calculation results, and achieve high precision of delay between holes , Improve the blasting efficiency, improve the effect of blasting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0079] The present invention is a tunnel blasting parameter design method based on digital electronic detonator detonation. The inventive method will be described in detail according to a specific engineering example, but the present invention is not limited to the specific implementation case.

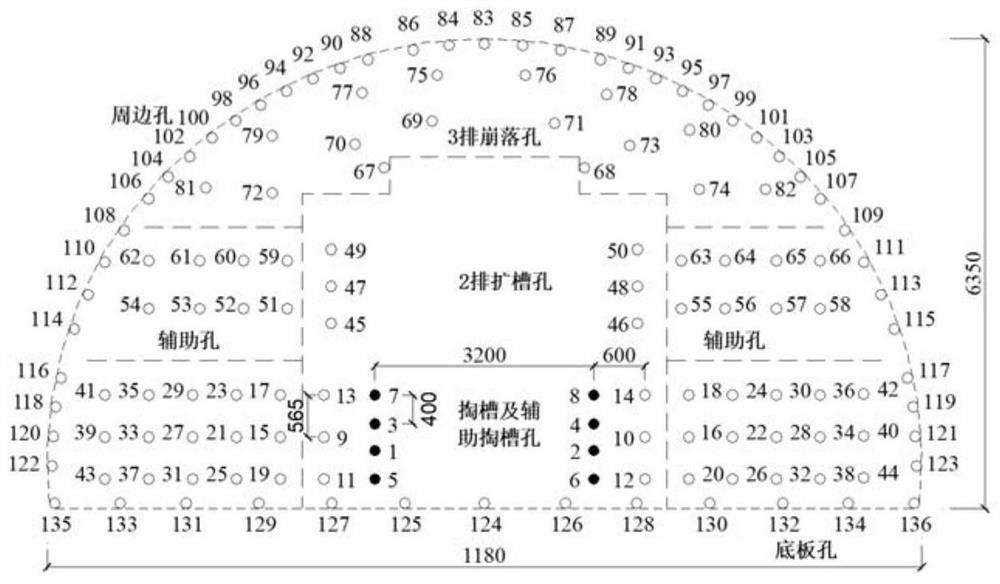

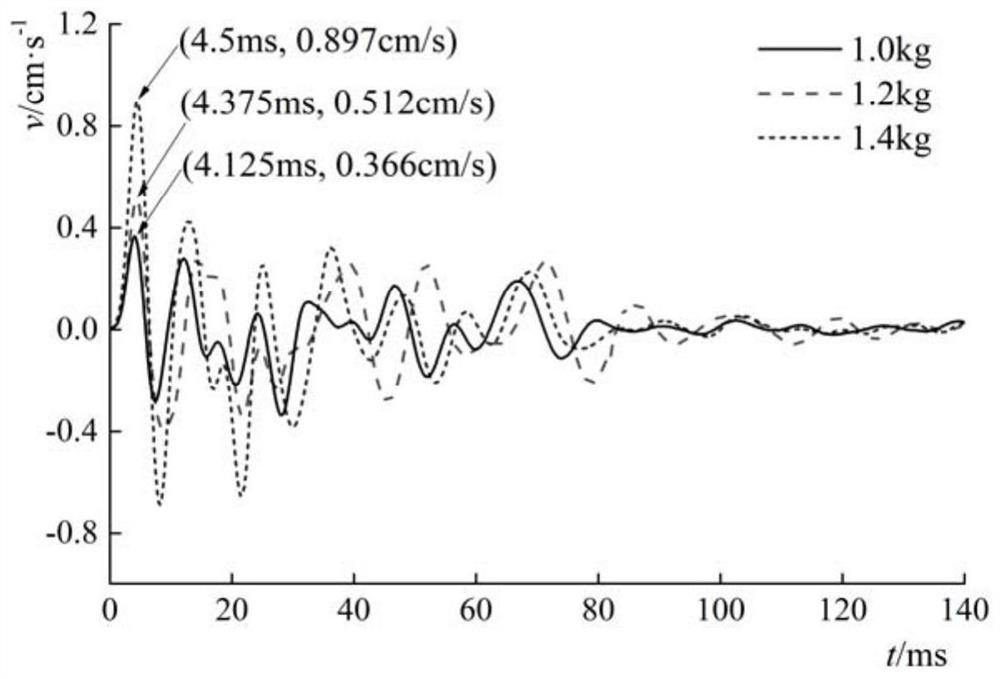

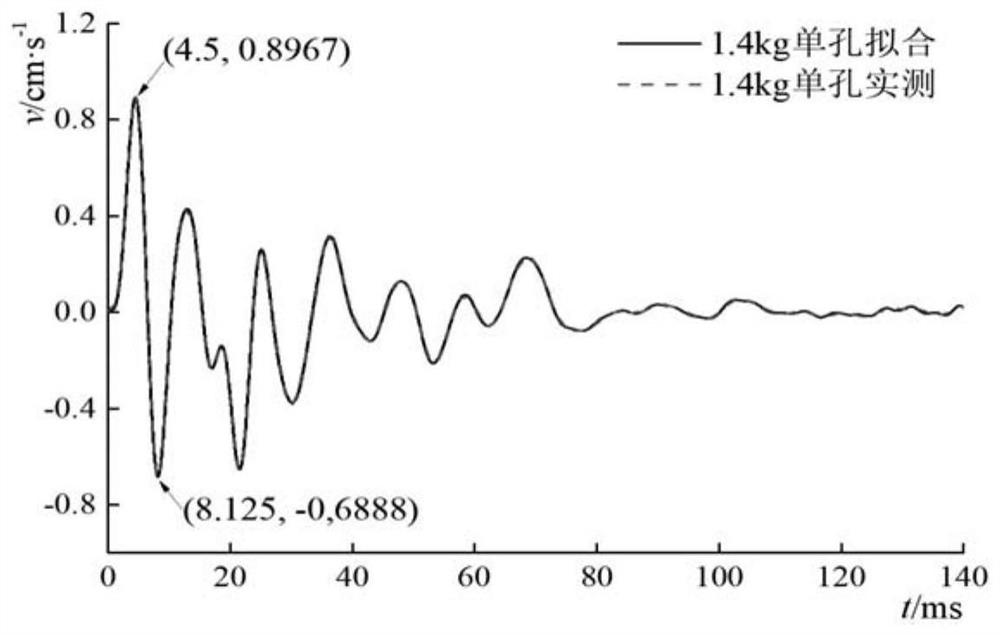

[0080] The project on which the present invention relies is the Guanyinqiao North Avenue Tunnel Project in Chongqing City. The project site is located in the downtown area of Chongqing. There are dense ground buildings and underground pipelines in the construction area. The tunnel is buried deep in 20-30m, which is a shallow buried tunnel. The blasting area is mainly gray and off-white sandstone, without adverse geological phenomena, and the tunnel surrounding rock category is Class IV. Referring to the "Blasting Safety Regulations" (GB6722-2014) and similar construction experience, according to the owner's requirements, the surface vibration velocity should not exceed 1.0cm / s. With...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com