Preparation method of dispensing electrode platform for ceramic packaging base, fixing method of resonator wafer and printing metal slurry

A technology of ceramic encapsulation and metal paste, applied in electrical components, impedance networks, etc., can solve the problems of easy falling off of glue dots, weak glue fixing method, etc., to improve the fixing firmness, good applicability and application effect, Satisfy the effect of low resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

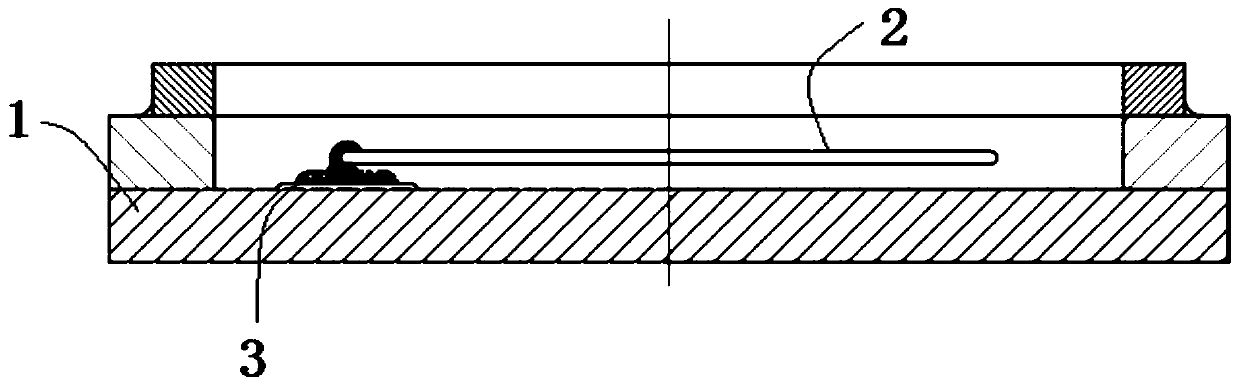

Embodiment 1

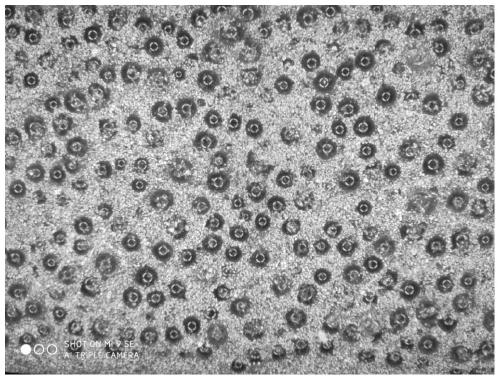

[0037] The preparation method of the dispensing electrode platform for the ceramic packaging base of this embodiment includes the following steps: printing the dispensing electrode platform with a printed metal paste at a predetermined position, and the printed metal paste forms a honeycomb shape after sintering at 1550°C The electrode platform substrate with a porous structure (the height of the electrode platform substrate is 30 μm), and then electroplated with nickel and gold in turn to obtain a dispensing electrode platform; the thickness of the nickel coating is 2-8 μm, and the thickness of the gold coating is 0.1-1 μm.

[0038] The printing metal paste is composed of the following weight percentages: 72% of tungsten powder; 6% of inorganic additives, including 5.6% of aluminum oxide, 0.3% of silicon dioxide, 0.05% of kaolin, and 0.05% of talcum powder; 10% of carbon powder, particle size 15μm; 12% organic vehicle, including 9% terpineol, 1.5% butyl carbitol, 0.05% plastic...

Embodiment 2

[0043] The difference between the preparation method of the glue dispensing electrode platform for the ceramic packaging base of this embodiment and the embodiment 1 is that the sintering temperature is 1600° C.

[0044] The printing metal paste is composed of the following components in weight percentage: 80% tungsten powder; 5% inorganic additives, including 4.65% aluminum oxide, 0.3% silicon dioxide, and 0.05% talcum powder; 5% starch, with a particle size of 40 μm; organic The carrier is 10% in total, including 7.5% of terpineol, 1.2% of butyl carbitol, 0.15% of hydrogenated castor oil as a thixotropic agent, 0.15% of lecithin as a leveling agent, and 1% of ethyl cellulose as a binder.

Embodiment 3

[0046] The difference between the preparation method of the dispensing electrode platform for the ceramic packaging base of this embodiment and the first embodiment is that the printing metal paste is composed of the following components in weight percentage: 60% of tungsten powder; 5% of inorganic additives, wherein 4.65% aluminum, 0.3% silicon dioxide, 0.05% talcum powder; 20% carbon powder, particle size 10μm; 15% organic carrier, including 11% terpineol, 2% butyl carbitol, thixotropic agent Hydrogenated castor oil 0.3%, leveling agent lecithin 0.2%, binder ethyl cellulose 1.5%.

[0047] In the above embodiments, the metal powder is described as tungsten powder, which may also be common electronic paste metals such as molybdenum powder and nickel powder, and its type is not limited.

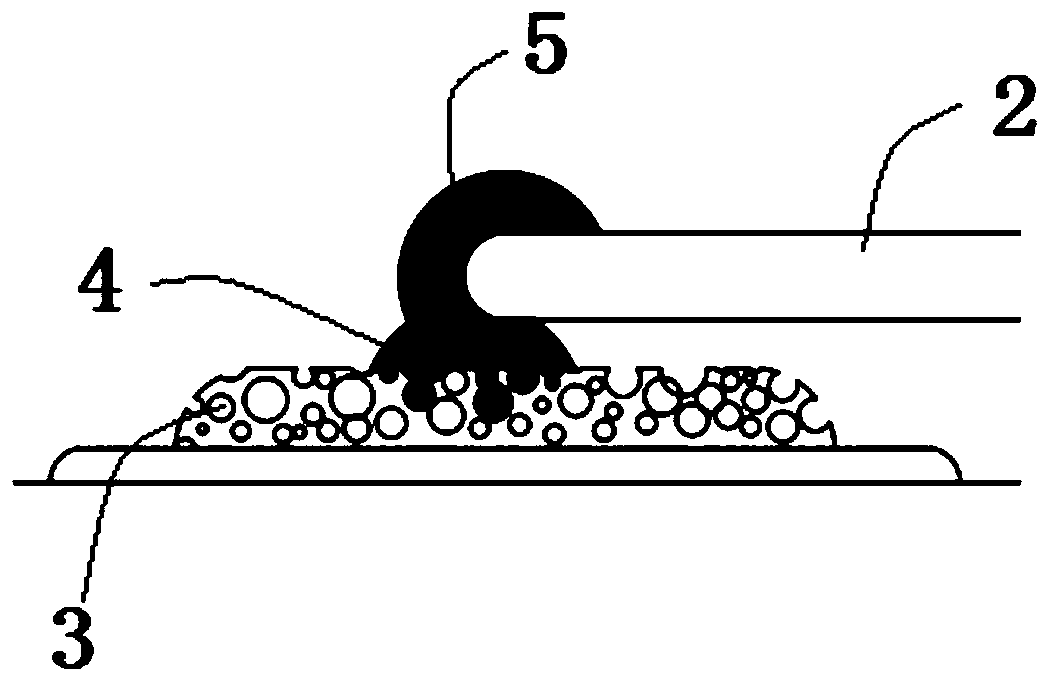

[0048] Two, the specific embodiment of the fixing method of the resonator chip of the present invention

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com