Dunaliella salina solid functional beverage and preparation method thereof

A technology of functional drinks and salina, which is applied in food science and other fields, can solve the problems of waste of active ingredients and difficulty in realizing the utilization of β-carotene in salina, and achieve the effect of improved solubility and slightly sweet taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The invention provides a preparation method of salina solid functional drink, comprising the following steps:

[0036] (1) mixing the beverage additive, salina dry powder and microcrystalline cellulose to obtain a mixture;

[0037] (2) mixing the mixture with water, and performing high-pressure homogenization treatment to obtain a mixed solution;

[0038] (3) Spray-drying the mixed solution to obtain the salina solid functional drink.

[0039] The invention mixes the beverage additive, salina dry powder and microcrystalline cellulose to obtain the mixture. In terms of parts by mass, the raw materials for preparation in the present invention preferably include 0.88-2.0 parts of blue-green algae dry powder, more preferably 1.0-2.0 parts. In the present invention, the mass percent content of β-carotene in the salt algae dry powder is preferably 3-10%, more preferably 6%; the particle diameter of the salt algae dry powder is preferably 0.01-0.10mm; the Salina dry powder ...

Embodiment 1

[0051] Weigh 20g of salina dry powder, add it to 500ml of distilled water, and treat it with a normal pressure homogenizer (1 standard atmosphere, 101Kpa) and a high pressure homogenizer (40000KPa) for 10 minutes respectively, and compare the dispersion effects of the two.

[0052] Test results such as figure 1 and figure 2 as shown, figure 1 It is the dispersion effect after 10 minutes of normal pressure homogenization. It can be seen that after normal pressure homogenization and standing for about 10 minutes, there is obvious precipitation at the bottom of the beaker, and there are lumps floating on the surface; figure 2 For the dispersion effect after high-pressure homogenization for 60 minutes, it can be seen that the solution is uniform and moderate in color after high-pressure homogenization, and there is no layered precipitation after standing for more than 60 minutes, and it can pass through the cellulose acetate filter membrane with a pore size of 0.45 microns. It...

Embodiment 2

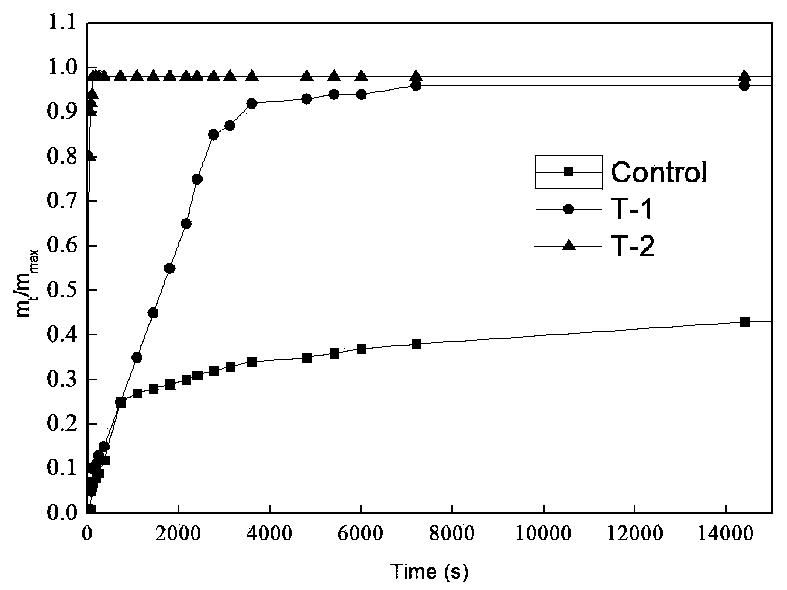

[0054] (1) Weigh 25g of salina dry powder with a percentage content of β-carotene of 5% in treatment 1 and treatment 2, add them to 1L distilled water respectively, prepare treatment 1 and treatment 2 respectively as follows, and take another 25g of salt Algal dry powder was used as blank control;

[0055] Treatment 1 (T-1): The mixture of salina dry powder and water is subjected to high-pressure homogenization for 10 minutes at a temperature of 80°C and a pressure of 400 bar, and then vacuum freeze-drying at a vacuum degree of 100 Pa;

[0056] Treatment 2 (T-2): The mixture of salina dry powder and water is homogenized under high pressure for 10 minutes at a temperature of 80°C and a pressure of 400 bar, and then spray-dried;

[0057] Blank control treatment (Control): Salina dry powder was not treated in any way.

[0058] (2) Add three treated dry algae powders to 200 mL of 40°C distilled water respectively. The dissolved system was stirred at 60 r / min with a constant spee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com