Method for separating and purifying cannabidiol

A cannabidiol, separation and purification technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry and other directions, can solve the problems of separation and purification of cannabidiol, and achieves easy recovery and reuse, high separation efficiency, and simple system Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

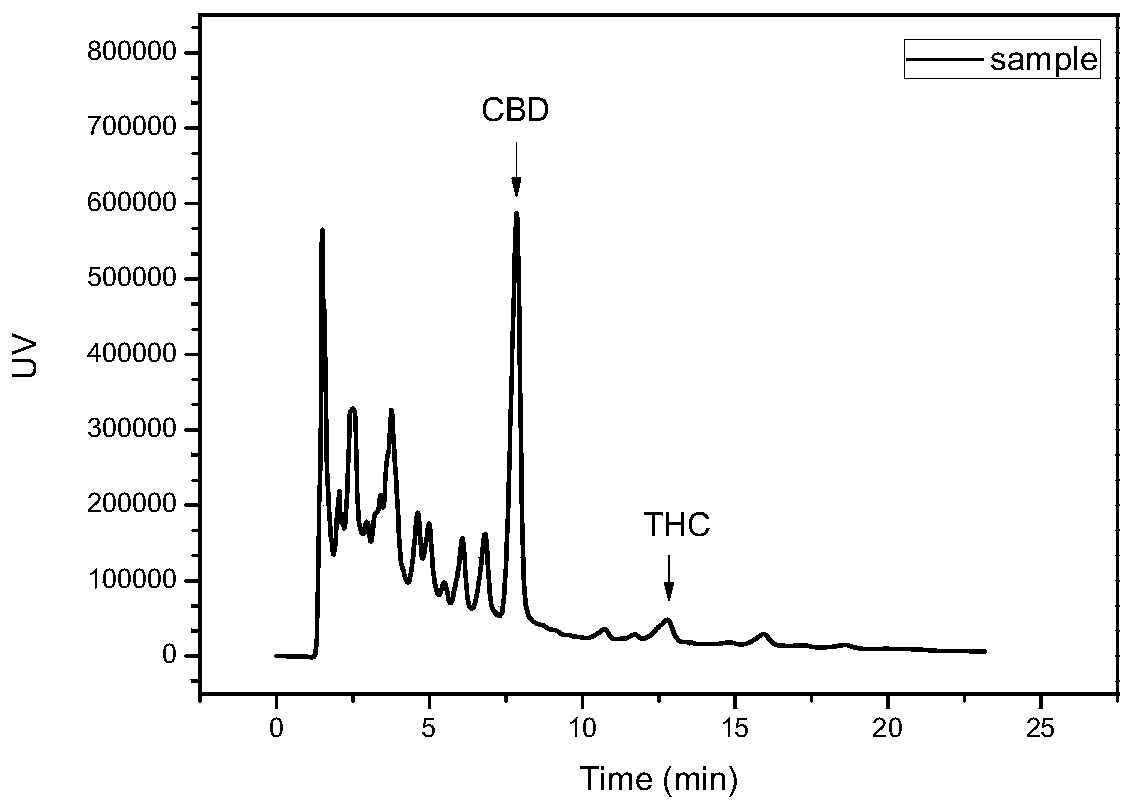

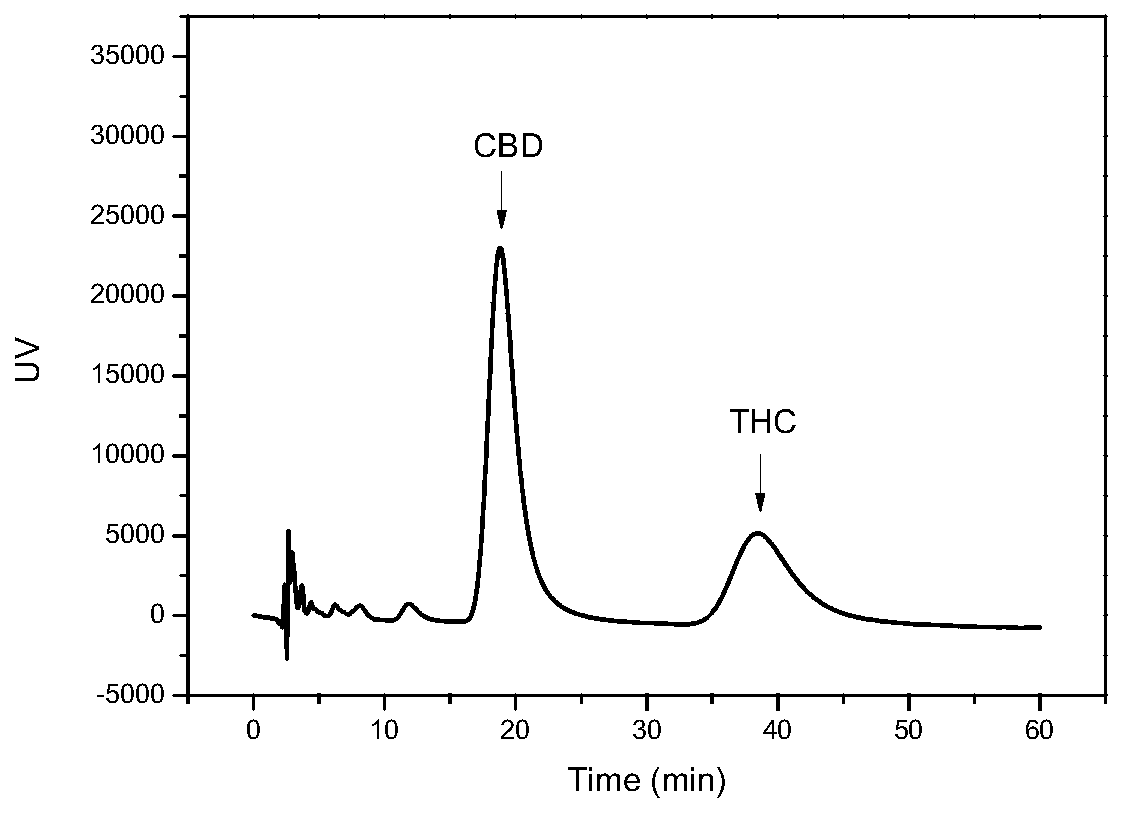

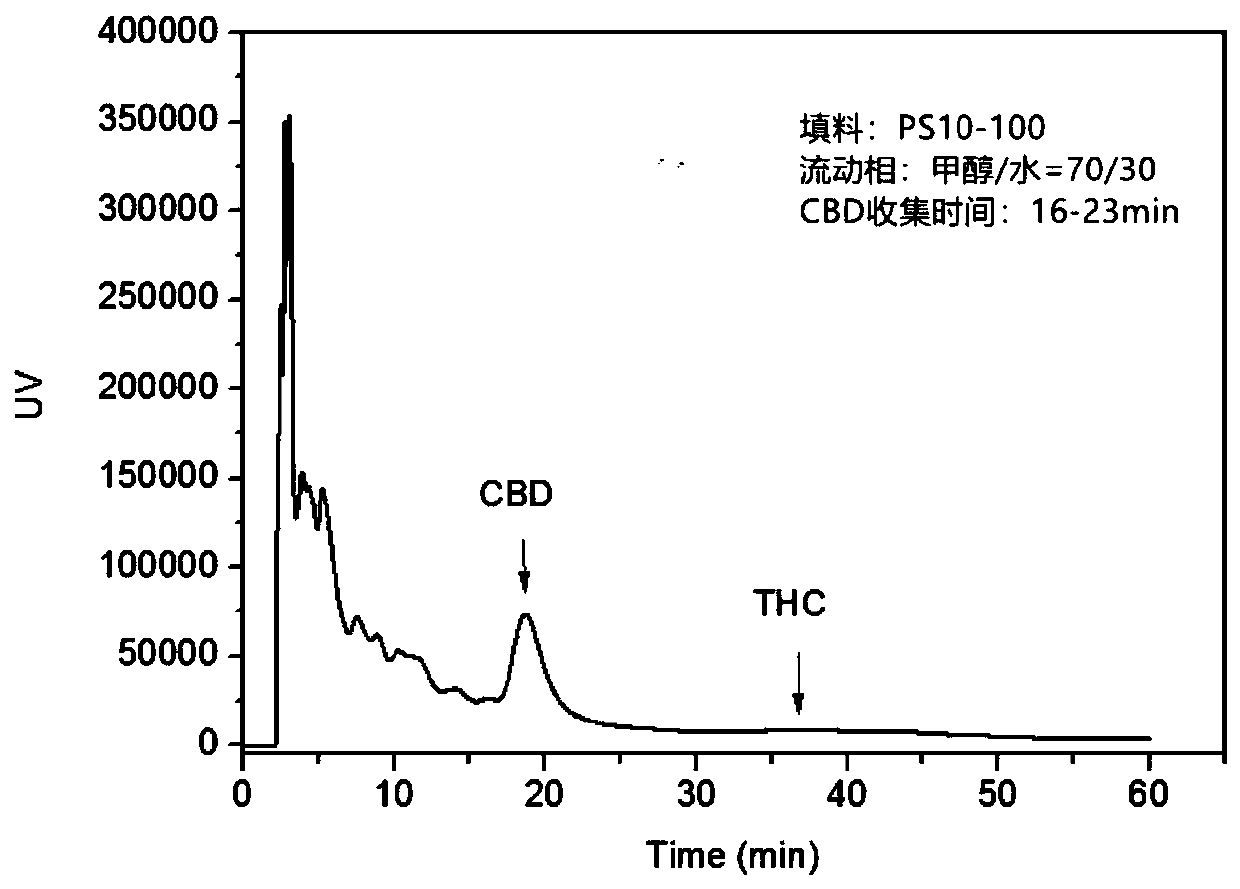

[0041] 1. Take PS10-100 adsorption material (particle size is 10-20μm, specific surface area is 800-900m 2 / g, pore diameter 400-600A, pore volume 0.7-0.9cm 3 / g) is the stationary phase column, the column volume is (column: 7.8*300mm column volume about 14.32mL); control the sample loading flow rate to 0.3BV / min, and complete the sample loading. During the sample loading process, the column pressure is 1.5Mpa; Wherein, the sample loaded is cannabis leaf extract (chromatogram as shown in figure 1 Shown), wherein, the massfraction of cannabidiol is 0.3%, and impurity is pigment, THC, grease matter.

[0042] 2. Use the mixed solution of methanol and water as the mobile phase, methanol / water=70 / 30 isocratic elution, the flow rate is 0.3

[0043] BV / min, collect 16-23min fractions; among them, during the elution process, the column pressure is 1.3-1.5MPa, during the elution process, the chromatogram of the fractions is as follows image 3 shown.

[0044] 3. The fraction in step...

Embodiment 2

[0048] 1. Take PS10-100 adsorption material (particle size is 10-20μm, specific surface area is 800-900m 2 / g, pore diameter 400-600A, pore volume 0.7-0.9cm 3 / g) is the stationary phase column, the column volume is (column: 7.8*300mm column volume about 14.32mL); control the sample loading flow rate to 0.3BV / min, and complete the sample loading. During the sample loading process, the column pressure is 1.5Mpa; Wherein, the sample loaded is cannabis leaf extract, wherein the mass fraction of cannabidiol is 0.3%, and the impurities are pigment, THC, and oil.

[0049] 2. Use the mixed solution of methanol and water as the mobile phase, methanol / water=80 / 20 isocratic elution, the flow rate is 0.3BV / min, and the fraction is collected for 12-20min; wherein, during the elution process, the column pressure is 1.3- 1.5Mpa.

[0050] 3. The fraction in step (2) is evaporated and crystallized to obtain the cannabidiol product with a purity of 99.2% and an extraction rate of 92%.

Embodiment 3

[0052] 1. Take PS10-100 adsorption material (particle size is 20-50μm, specific surface area is 800-1000m 2 / g, pore diameter 400-800A, pore volume 0.7-1cm 3 / g) is the stationary phase column, the column volume is (column: 7.8*300mm column volume about 14.32mL); control the sample loading flow rate to 0.3BV / min, and complete the sample loading. During the sample loading process, the column pressure is 1.5Mpa; Wherein, the sample loaded is cannabis leaf extract, wherein the mass fraction of cannabidiol is 0.3%, and the impurities are pigment, THC, and oil.

[0053] 2. Use the mixed solution of methanol and water as the mobile phase, methanol / water=70 / 30 isocratic elution, the flow rate is 0.3BV / min, and the fraction is collected for 16-23min; wherein, during the elution process, the column pressure is 1.2- 1.4Mpa.

[0054] 3. The fraction in step (2) is evaporated and crystallized to obtain the cannabidiol product with a purity of 98.9% and an extraction rate of 93.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com