Controllable preparation of MIL material, and application of MIL material in separation enrichment of furan compounds

A technology for separation and enrichment of compounds, applied in other chemical processes, organic chemistry, chemical instruments and methods, etc., can solve the problems of low concentration and difficult separation, and achieve the effect of simple process, low energy consumption, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Controllable Preparation of micro MIL-53(Al)

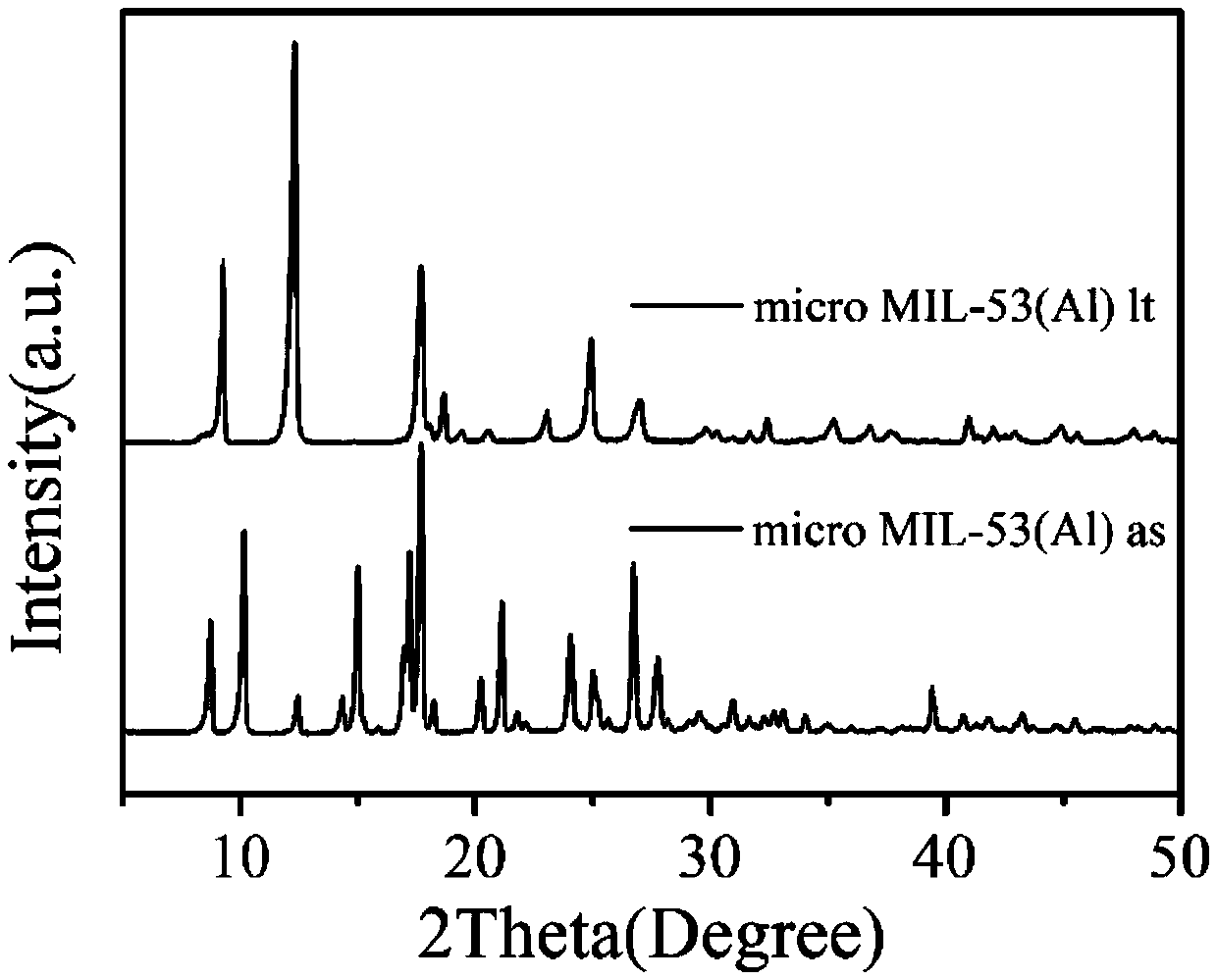

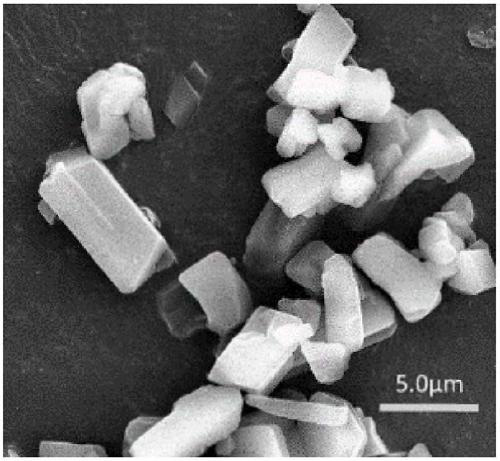

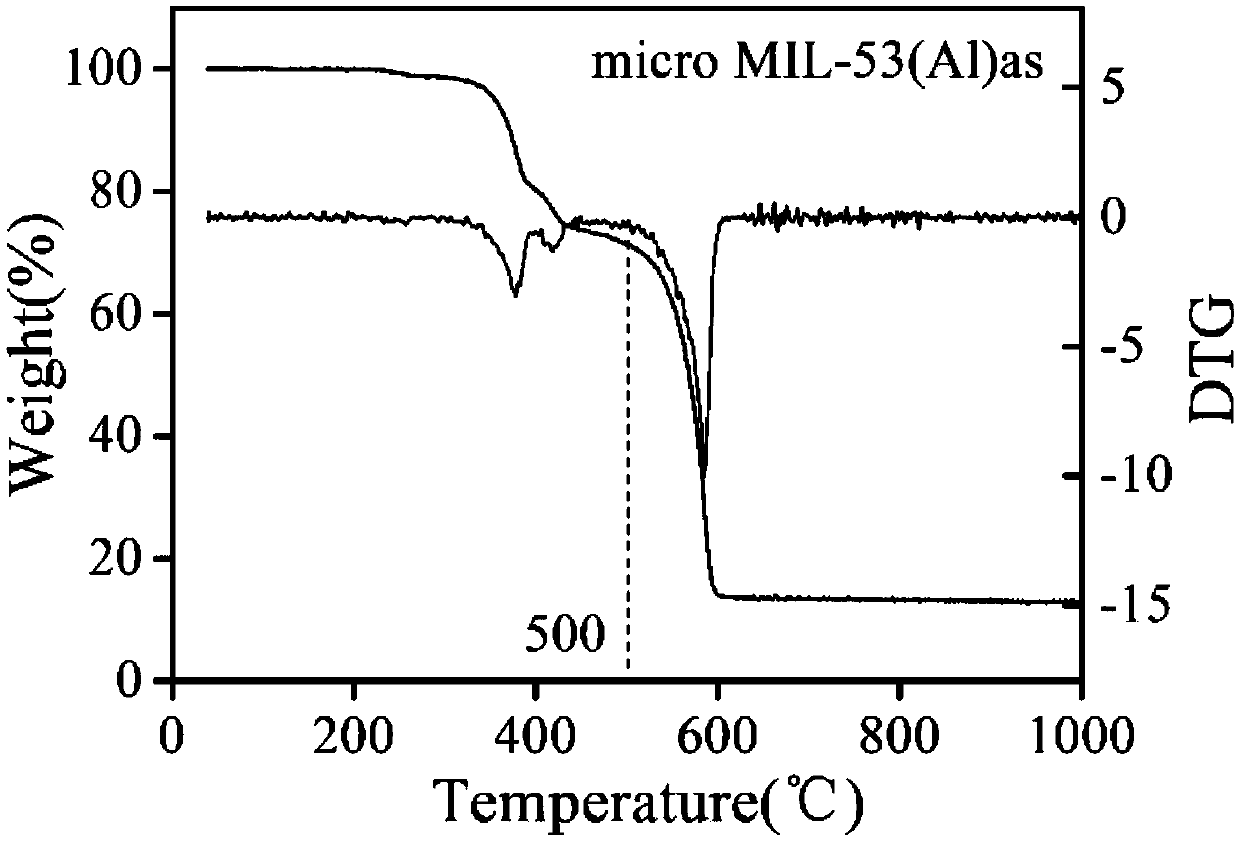

[0047] Uniformly disperse 13g of aluminum nitrate nonahydrate and 2.88g of terephthalic acid in 50ml of ultrapure water to obtain a mixed precursor solution, transfer it to a fully enclosed stainless steel reactor, set the reaction temperature to 220°C, and in a stable reaction environment Keep for 72h. After the reaction was completed, the heating was stopped and cooled to room temperature naturally to obtain a white powder sample. The samples were centrifuged and washed 3 times with ultrapure water, and the centrifugation conditions were: 15000r / min, 5min, 25°C. The samples were placed in an air atmosphere, and the drying temperature was set at 85°C for drying. The fully dried powder sample was fully ground to obtain the material micro MIL-53(Al)as. figure 1 The X-ray diffraction spectrum of micro MIL-53(Al)as is given, figure 2 The scanning electron microscope image of micro MIL-53(Al)as is given, and the scale bar ...

Embodiment 2

[0049] micro MIL-53(Al) for separation and enrichment of furan compound-furfural

[0050] The adsorption performance of biomass furfural on micro MIL-53(Al)lt was tested by loss method. At room temperature, uniformly disperse 0.050g micro MIL-53(Al)lt in 0.50ml furfural aqueous solution, and absorb for 0-20min under continuous mixing. Obtain the supernatant after adsorption equilibrium by centrifugation, and analyze the concentration of furfural in the supernatant by liquid chromatography. In order to correct the adsorption data, the blank comparison experiment was carried out under the same conditions. Experiments show that the adsorption reaches equilibrium within 20 minutes. Equilibrium adsorption capacity Q(mg g -1 ) can be calculated by the following formula:

[0051] Q=V·(C 0 –C e )·m -1

[0052] Wherein V is the volume (mL) of furfural aqueous solution used, C 0 is the concentration of furfural in the aqueous solution before adsorption (g L -1 ), C e is the c...

Embodiment 3

[0054] NH 2 - Controlled preparation of MIL-53(Fe)

[0055] Dissolve 0.96g of ferric chloride hexahydrate, 0.58g of 2-aminoterephthalic acid, and 0.05g of benzoic acid in 30ml of solvent to obtain a precursor mixed solution. The solvent is N,N-dimethylformamide (DMF) and water (The volume ratio of DMF and water is 3:1). The precursor solution was transferred to a fully-sealed stainless steel reactor, and the constant temperature was set at 150°C for 24 hours. After the reaction was completed, the heating was stopped, and it was naturally cooled to room temperature to obtain a powder sample. The sample was centrifuged and washed once with the solvent DMF, and the centrifugation conditions were: 15000r / min, 5min, 25°C. Take 30ml of DMF and transfer the sample to a stainless steel reaction kettle, and keep the temperature at 150°C for 5.5h again. After the reaction was completed, the heating was stopped and cooled to room temperature naturally. Without changing the centrifug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com