Special-shaped multi-dimensional phase change radiator

A heat sink and dimensioning technology, applied in indirect heat exchangers, heat exchange equipment, lighting and heating equipment, etc., can solve problems such as large temperature difference, low heat exchange efficiency of fins, uneven heat distribution, etc., and achieve reduction Effect of temperature difference, improvement of heat exchange efficiency, and low overall efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment one (comparative example):

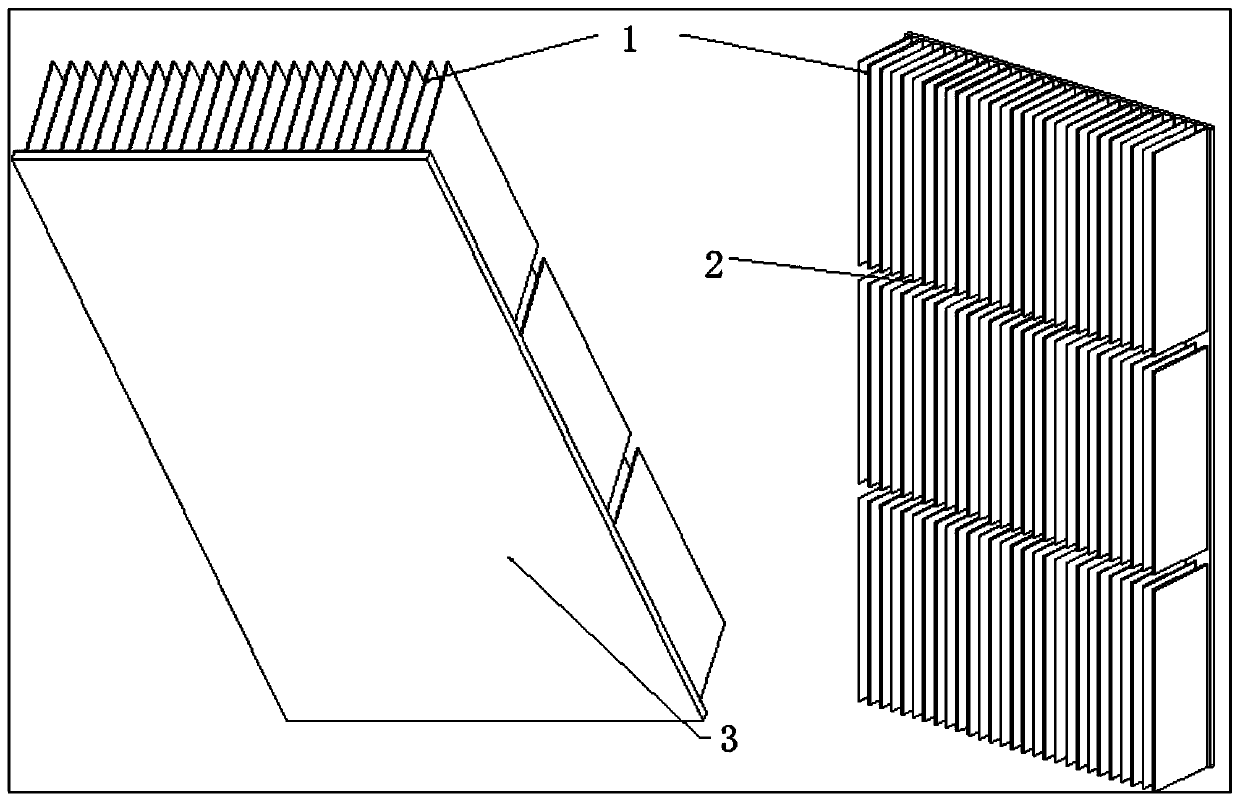

[0046] In the application of natural convection heat dissipation, it is often applied to heat dissipation with multiple heat sources, and the heat sink has a relatively high vertical height such as figure 1It is a conventional natural convection radiator shape structure, radiator structure size: width 200 ~ 650mm x height 200 ~ 700mm x depth 45 ~ 120mm (fin height), tooth bottom thickness: 1.5 ~ 3.5; tooth top thickness: 1.0 ~ 2.0mm ;Teeth pitch: 12~18mm; The fins of this radiator are generally arranged vertically from bottom to top, and grooves of 15~30mm are processed according to needs.

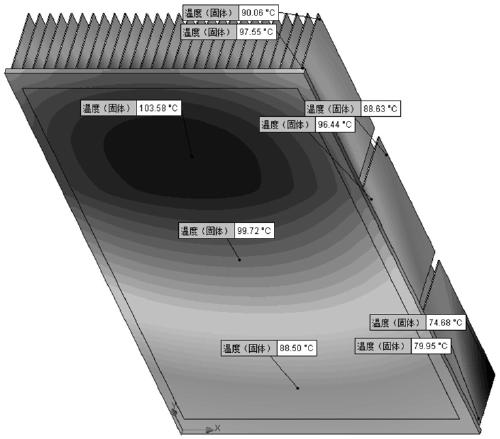

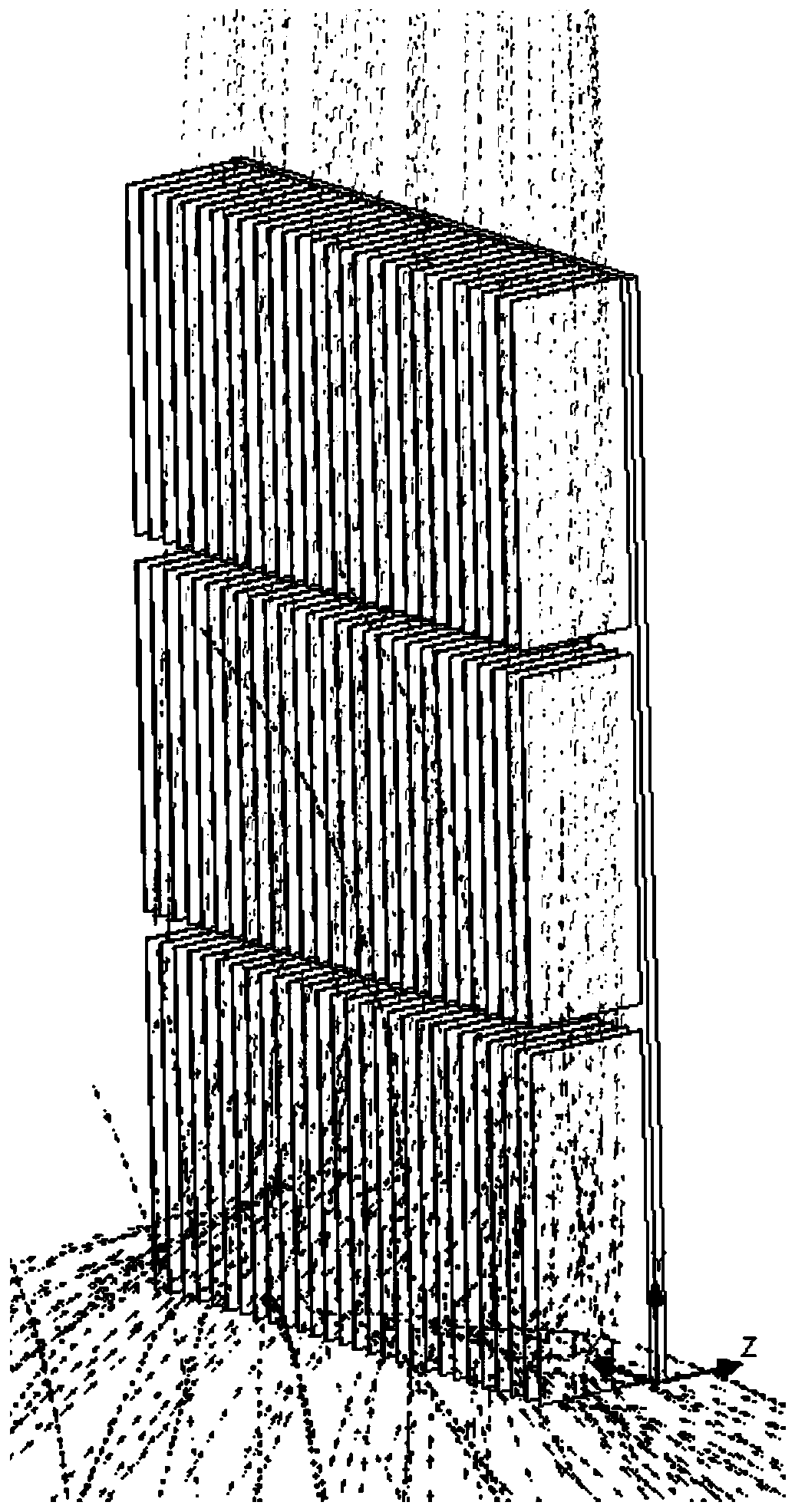

[0047] figure 2 image 3 Using the above model, the heat sink temperature gradient diagram and the fluid vector diagram are analyzed by natural convection simulation; from the temperature gradient distribution of the substrate, the temperature gradient of the heat source area increases continuously from bottom to top, while the temperature...

Embodiment 2

[0050] The principle of this special-shaped multi-dimensional phase change radiator: the phase change area of the new special-shaped multi-dimensional phase change radiator is a vacuum-sealed sealed shell composed of a phase change substrate steam cavity and a phase change fin steam cavity, and the inner surface of the phase change substrate shell Sinter the multi-component sintered powder capillary layer, and inject a certain amount of phase change working fluid into the sealed shell. When the heating element works, heat is generated, which is transferred to the inner surface of the new special-shaped multi-dimensional phase change radiator through the phase change cold plate shell (the material is generally aluminum and aluminum alloy), and the heat is transferred to the capillary structure layer and the inner surface of the shell through heat conduction, thereby Heat exchange occurs with the working fluid, the working fluid absorbs heat, changes from a liquid phase to a va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com