A kind of detection method of impurities in parecoxib sodium synthesis process

A parecoxib sodium and synthesis process technology, which is applied in the field of drug analysis and detection, can solve the problems of excessive sulfonylation derivative impurities without comprehensive detection, a large number of methods, and high analysis costs, and achieve wide coverage and separation The effect of good effect, high sensitivity and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

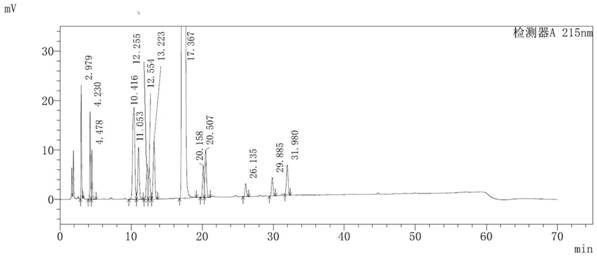

Embodiment 1

[0044] The method for detecting impurities in the parecoxib sodium synthesis process of the present embodiment adopts the following steps:

[0045] (1) Take an appropriate amount of the sample of parecoxib sodium to be tested, accurately weigh it, add acetonitrile-water (40:60, v / v) to dissolve and quantitatively dilute to prepare 0.5 mg of parecoxib sodium per 1 mL to be tested The solution of the sample, as the solution to be tested;

[0046] (2) Take 10 μL of the solution to be tested and inject it into a liquid chromatograph, record the chromatogram, and calculate the content of impurities in each process according to the standard curve method.

[0047] The chromatographic conditions for liquid phase detection are: chromatographic column: YMC-Pack ODS-AQ (4.6×250mm, 5μm); mobile phase A: 0.01mol / L disodium hydrogen phosphate solution (adjust pH to 3.0 with phosphoric acid); mobile phase B: acetonitrile-methanol (75:25, v / v); detection wavelength: 215 nm; column temperatur...

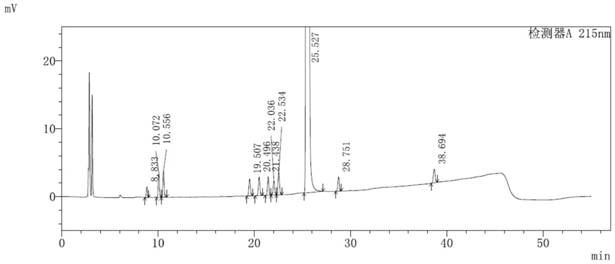

Embodiment 2

[0054] The method for detecting impurities in the parecoxib sodium synthesis process of the present embodiment adopts the following steps:

[0055] (1) Take an appropriate amount of the sample of parecoxib sodium to be tested, accurately weigh it, add acetonitrile-water (40:60, v / v) to dissolve and quantitatively dilute to prepare 0.5 mg of parecoxib sodium per 1 mL to be tested The solution of the sample, as the solution to be tested;

[0056] (2) Take 10 μL of the solution to be tested and inject it into a liquid chromatograph, record the chromatogram, and calculate the content of impurities in each process according to the standard curve method.

[0057] The chromatographic conditions for liquid phase detection are: chromatographic column: Welch Ultimate XB-C18 (4.6×250mm, 5μm); mobile phase A: 0.01mol / L disodium hydrogen phosphate solution (adjust pH to 3.2 with phosphoric acid); mobile phase B : acetonitrile-methanol (80:20, v / v); detection wavelength: 215 nm; column tem...

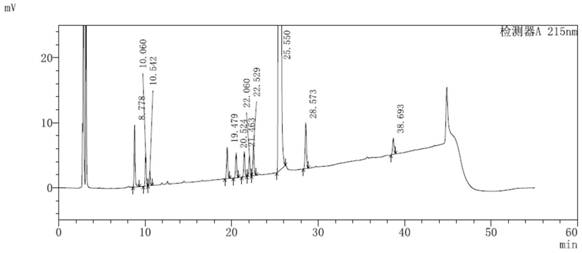

Embodiment 3

[0064] The method for detecting impurities in the parecoxib sodium synthesis process of the present embodiment adopts the following steps:

[0065] (1) Take an appropriate amount of the sample of parecoxib sodium to be tested, accurately weigh it, add acetonitrile-water (40:60, v / v) to dissolve and quantitatively dilute to prepare 0.5 mg of parecoxib sodium per 1 mL to be tested The solution of the sample, as the solution to be tested;

[0066] (2) Take 10 μL of the solution to be tested and inject it into a liquid chromatograph, record the chromatogram, and calculate the content of impurities in each process according to the standard curve method.

[0067] The chromatographic conditions for liquid phase detection are: chromatographic column: YMC-Pack ODS-AQ (4.6×250mm, 5μm); mobile phase A: 0.01mol / L disodium hydrogen phosphate solution (adjust pH to 2.8 with phosphoric acid); mobile phase B: acetonitrile-methanol (85:15, v / v); detection wavelength: 215 nm; column temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com