Method for synthesizing CsPbI3 perovskite nanocrystals by using room-temperature non-polar solvent system

A non-polar solvent, nanocrystal technology, applied in nanotechnology, chemical instruments and methods, lead compounds, etc., can solve the problems of difficult purification, easy ion migration, poor phase stability, etc., to achieve low cost, high yield, High-quality and stable compositing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

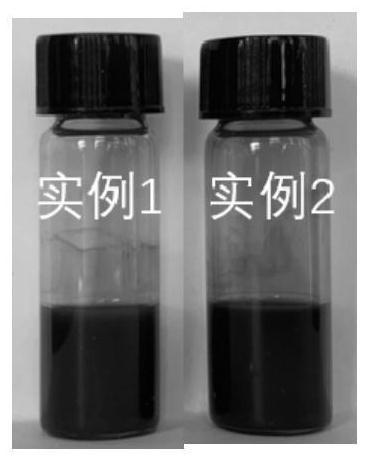

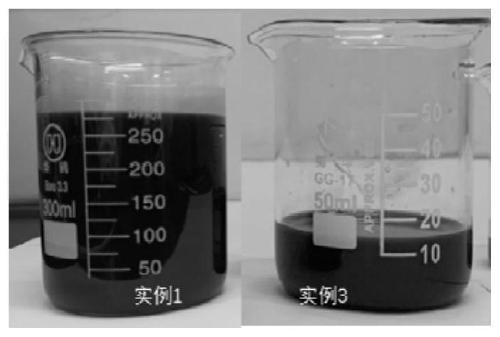

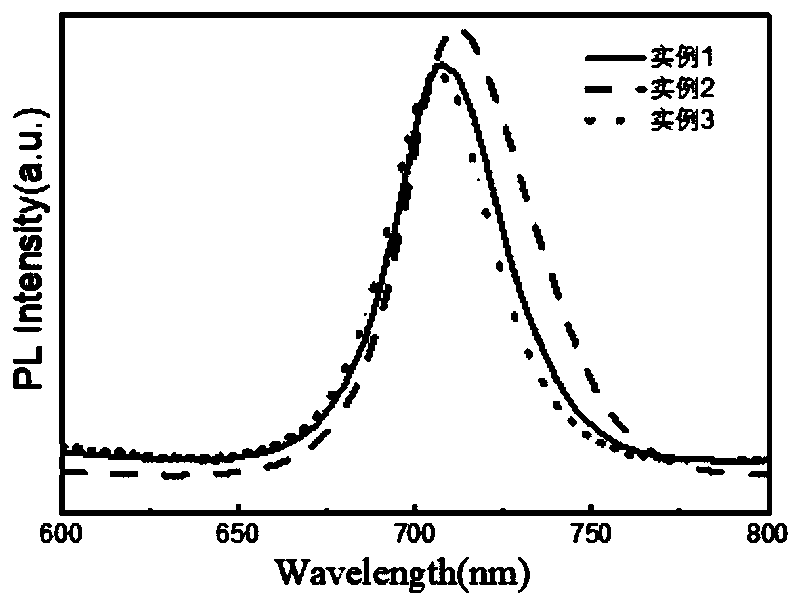

Embodiment 1

[0029] (1) ultrasonically dissolve 1mmol PbI in 20ml toluene 2 , 2mmol tetraoctyl ammonium iodide, obtain the Pb precursor;

[0030] (2) Dissolve 0.3mmol cesium carbonate (CsCO 3 ), to obtain the Cs precursor;

[0031] (3) ultrasonically dissolve 0.3 mmol oleylamine iodine in 10 mL of toluene solution;

[0032] (4) Inject the Cs precursor into the lead precursor with a syringe, stir and react for 4min, add 3mL oleylaminoiodotoluene solution, and stir for 4min to obtain CsPbI 3 Nanocrystalline stock solution;

[0033] (5) Add 30mL of ethyl acetate to the above-mentioned nanocrystal stock solution, centrifuge to take the precipitate, disperse the precipitate with 6mL of n-hexane, and obtain CsPbI 3 Nanocrystalline.

Embodiment 2

[0035] Using the same process as in Example 1, the difference is that the cesium carbonate in step 2) of Example 1 is replaced with cesium acetate, and other conditions remain the same.

Embodiment 3

[0037] Using the same process as in Example 1, the difference is that the amount of each raw material is 15 times that of Example 1, and other conditions remain the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com