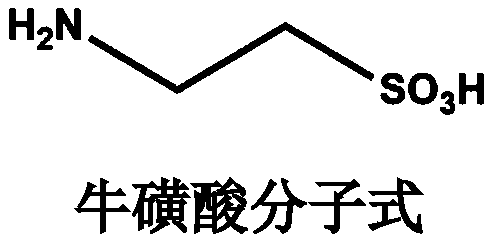

Method for preparing taurine from sodium isethionate

A technology of sodium isethionate and taurine, applied in the direction of sulfonic acid preparation, sulfonate preparation, chemical instruments and methods, etc., can solve the problem of difficult catalyst recovery, high energy consumption cost, and homogeneous catalysts that cannot be recycled and applied mechanically and other problems, to achieve the effect of being suitable for industrial production, shortening the reaction time, and improving the electrophilic characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 696g of sodium isethionate solution (10wt%) was placed in a 1L high-pressure reactor, and 0.209g of Zr 2 MoO 4 (PO 4 ) 2 Catalyst, feed 160g liquid ammonia subsequently, make the molar ratio of liquid ammonia and sodium isethionate be 20, the temperature of reaction system is raised to 120 ℃, system pressure is 6MPa, reaction 30min, the sodium taurate obtained by ammonolysis reaction Yield 92.0%.

[0038]The reaction liquid was distilled and concentrated under reduced pressure at 75°C and -0.07MPa, and the concentration of sodium taurate was increased to 35wt%. At 45°C, concentrated sulfuric acid was added to adjust the pH of the system to 6, and then cooled to 15°C for crystallization. The one-way yield of taurine is 75.0%, and the mother liquor can be applied to the ammonolysis reaction again, and the total yield of taurine is 94.0%.

Embodiment 2

[0040] 740g of sodium isethionate solution (6wt%) was placed in a 1L high-pressure reactor, and 0.222g of Zr 2 MoO 4 (PO 4 ) 2 Catalyst, feed 81.6g liquid ammonia subsequently, make the molar ratio of liquid ammonia and sodium isethionate be 16, the reaction system is heated to 100 ℃, system pressure is 7MPa, reaction 55min, the taurine that this step reaction can obtain Sodium acid yield 93%.

[0041] The reaction solution was distilled and concentrated under reduced pressure at 78°C and -0.067MPa, and the concentration of sodium taurate was increased to 33wt%. At 85°C, concentrated sulfuric acid was added to adjust the pH of the system to 9, and then cooled to 30°C for crystallization. The one-way yield of taurine is 72.0%, and the mother liquor can be applied to the ammonolysis reaction again, and the total yield of taurine is 92.1%.

Embodiment 3

[0043] 724g of sodium isethionate solution (12wt%) was placed in a 1L high-pressure reactor, and 0.608g of ZrMo 2 o 8 Catalyst, feed 110g liquid ammonia subsequently, make the molar ratio of liquid ammonia and sodium isethionate be 11, the reaction system is heated to 140 ℃, system pressure is 4MPa, reaction 80min, the taurine that this step reaction can obtain The sodium yield was 91.0%.

[0044] The reaction solution was distilled and concentrated under reduced pressure at 85°C and -0.06MPa, and the concentration of sodium taurate was increased to 50wt%. At 60°C, concentrated sulfuric acid was added to adjust the pH of the system to 7, and then cooled to 35°C for crystallization. The one-way yield of taurine is 73.5%, and the mother liquor can be applied to the ammonolysis reaction again, and the total yield of taurine is 96.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com