Preparation method of reshapeable shape memory elastomer based on eutectic crystal

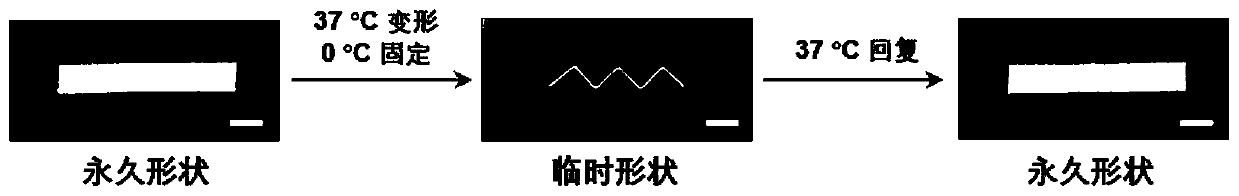

An elastomer and memory technology, applied in the field of chemically cross-linked copolyester with low-temperature shape memory effect and its preparation, can solve the problems of reducing material modulus and thermal stability, achieve excellent shape memory performance, accelerate degradation rate, The effect of reducing stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

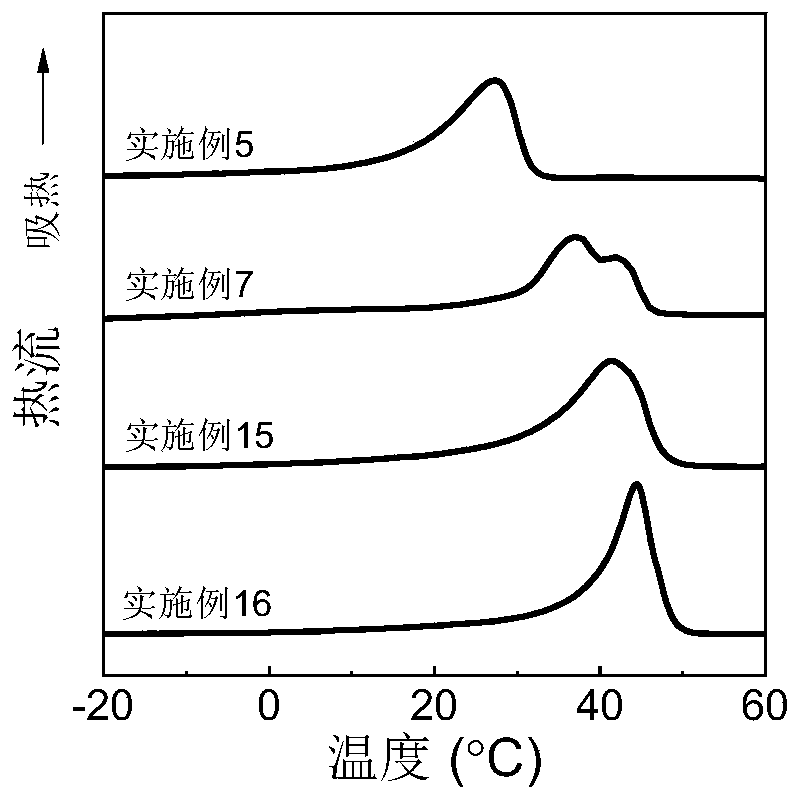

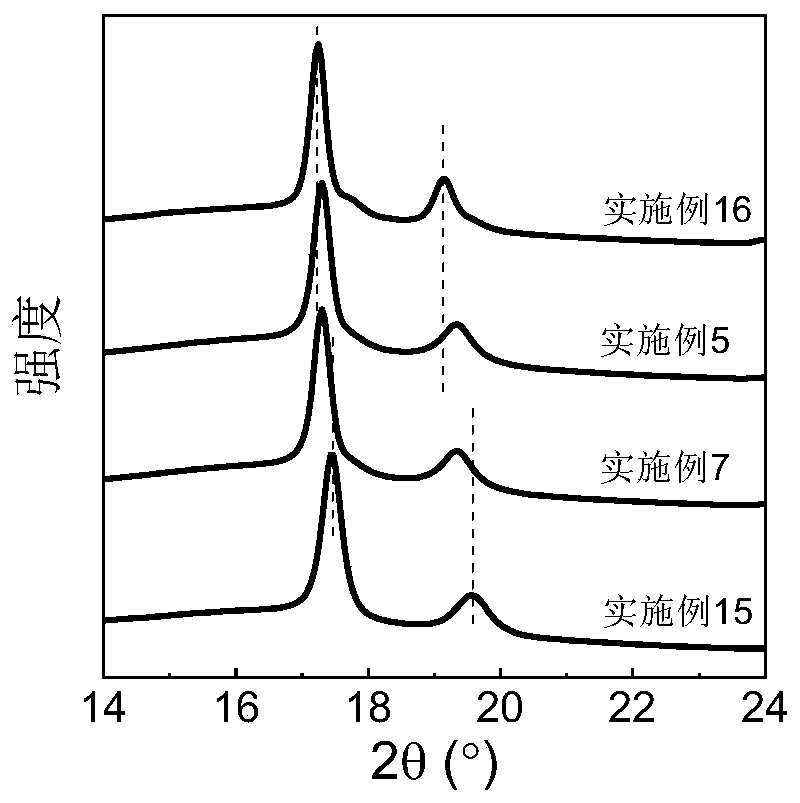

[0047] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0048] (1) Preparation of polyester diol

[0049] The polyester diol is prepared by the ring-opening polymerization method, and the specific steps can refer to the content introduced in the Chinese patent document CN107022070B.

[0050] Table 1: Initiators, monomers, catalysts, reaction temperatures, and reaction times used in the preparation of homopolyesters 1 to 4

[0051]

[0052] Note: Sn(Oct) 2 For stannous octoate.

[0053] (2) Preparation of cocrystallizable copolyesterdiol

[0054] The specific steps for preparing eutectic copolyesterdiol by transesterification are: uniformly mixing two or more cocrystallizable polyesterdiols and a transesterification catalyst in an appropriate amount of solvent, the transesterification catalyst accounting for 0.2-2.0 wt% of the total mass of the diol; after the solvent is removed, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com