Method for preparing C-axis preferred orientation aluminum nitride polycrystalline film through magnetron sputtering and aluminum nitride polycrystalline film

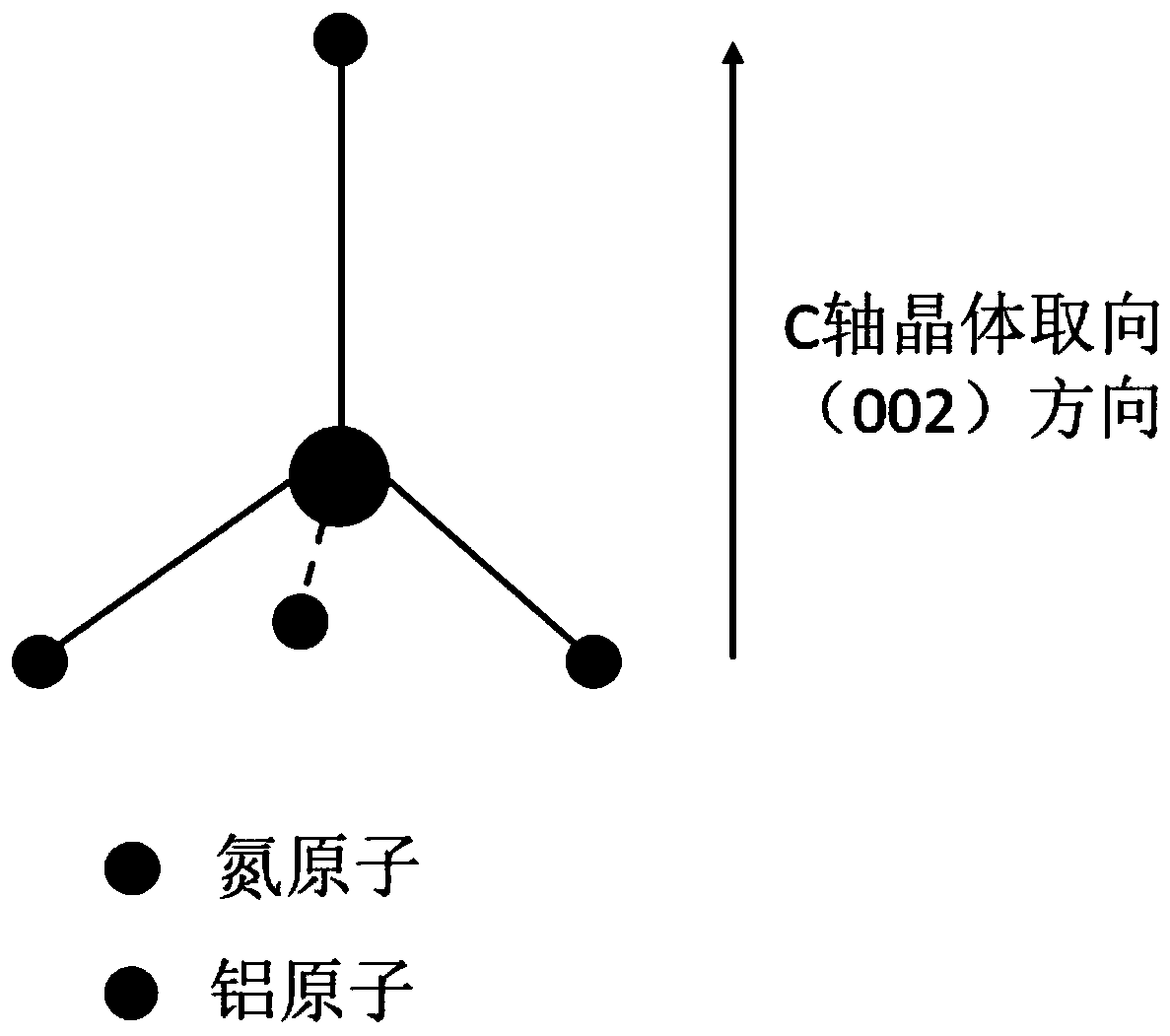

A technology of magnetron sputtering and preferred orientation, applied in chemical instruments and methods, sputtering coating, polycrystalline material growth, etc., can solve the problem of low motion energy, improve crystallization degree, improve piezoelectric response and electromechanical Effect of high coupling coefficient and crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

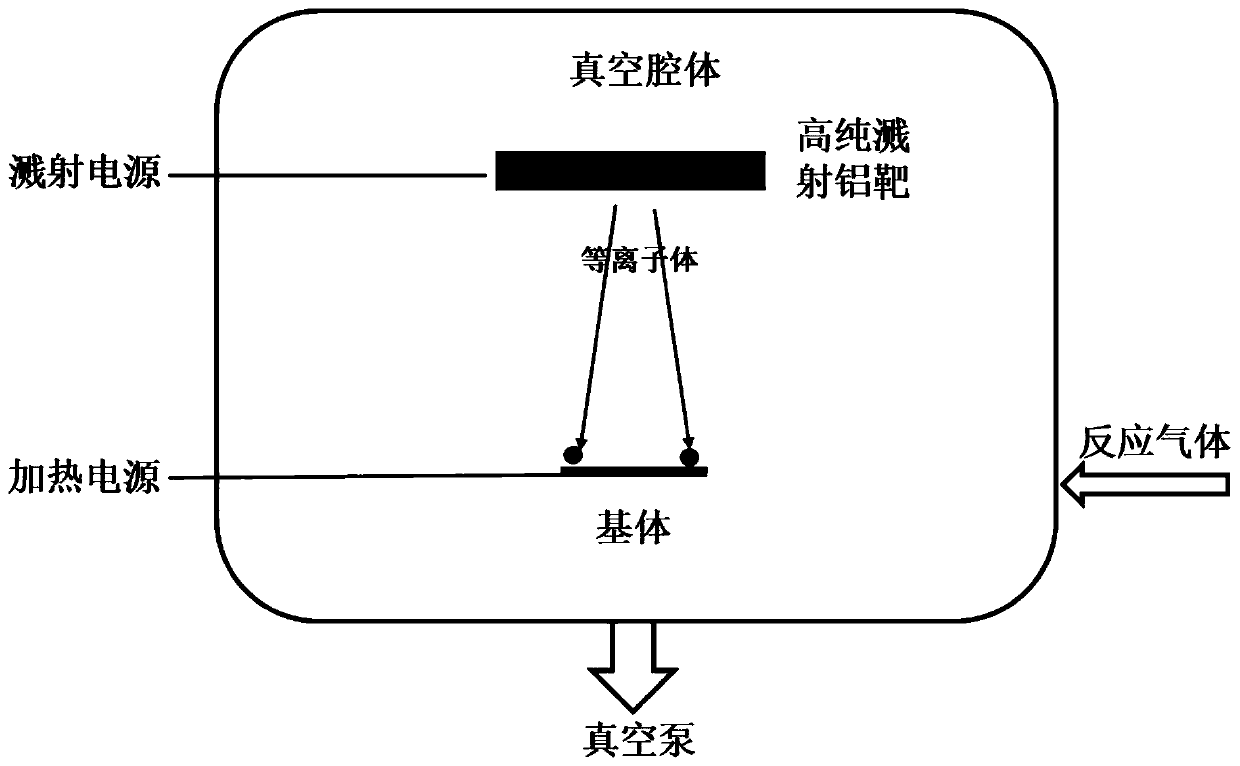

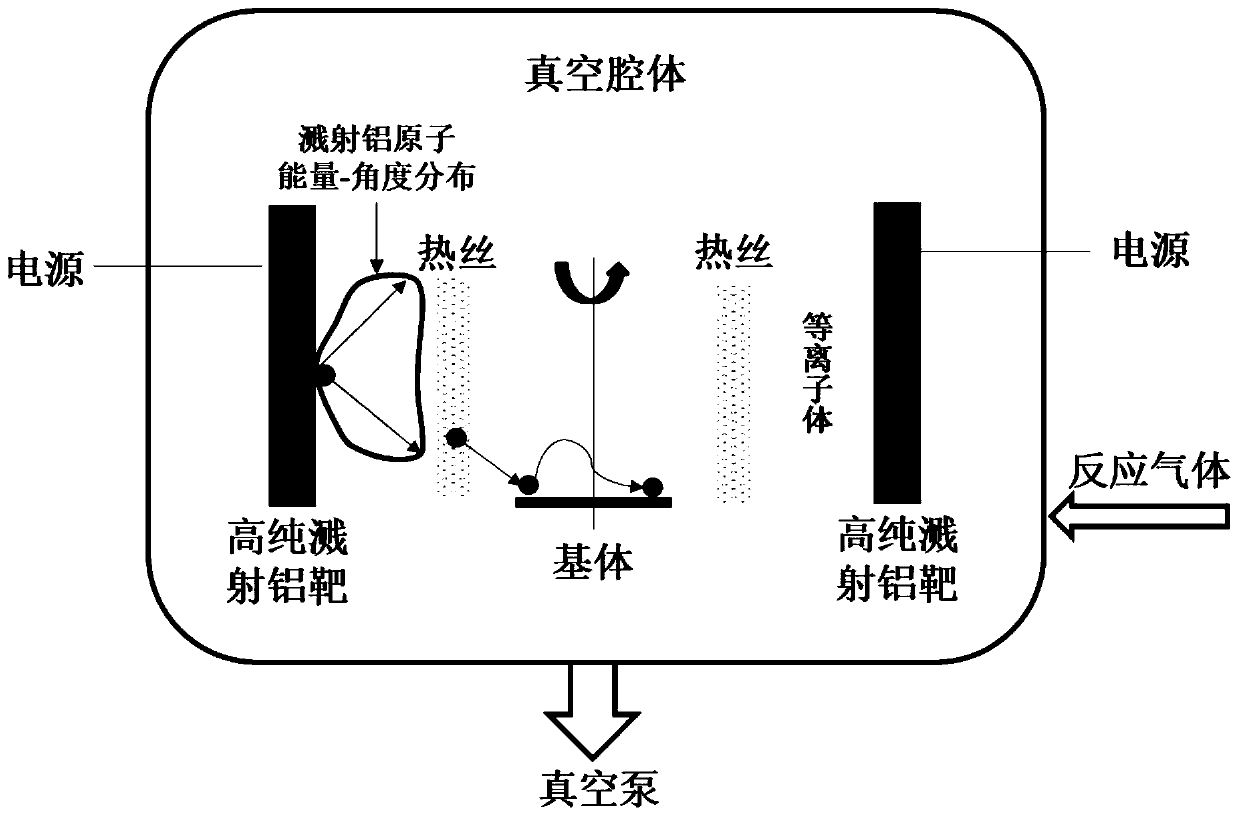

[0051] Magnetron sputtering to prepare C-axis preferred orientation aluminum nitride polycrystalline film, the steps are as follows:

[0052] The semiconductor material substrate is on a 2-inch silicon substrate, the silicon substrate is P-type doped, the thickness is 0.5mm, and the surface polishing roughness is less than 8nm; the substrate is placed horizontally on the sample stage in the vacuum chamber, and the sample stage can rotate around the center. The platform controls the substrate temperature to 300°C;

[0053] 4 columnar high-purity sputtering aluminum targets are vertically and evenly distributed around the sample stage (the normal direction of the silicon substrate surface is perpendicular to the normal direction of the surface of the high-purity sputtering aluminum target), and the diameter of the sputtering aluminum target is 80mm, which is higher than the surface of the substrate 200mm, the horizontal distance between the surface of the sputtering target and t...

Embodiment 2

[0060] Magnetron sputtering to prepare C-axis preferred orientation aluminum nitride polycrystalline film, the steps are as follows:

[0061] The semiconductor material substrate is on a 2-inch silicon substrate, the silicon substrate is P-type doped, the thickness is 0.5mm, and the surface polishing roughness is less than 8nm; the substrate is placed horizontally on the sample stage in the vacuum chamber, and the sample stage can rotate around the center. The platform controls the substrate temperature to 300°C;

[0062] A single annular high-purity sputtering aluminum target surrounds the sample stage (the normal direction of the surface of the silicon substrate is perpendicular to the normal direction of the surface of the high-purity sputtering aluminum target), the inner diameter of the sputtering aluminum target is 250mm, the wall thickness is 15mm, and it is higher than the substrate The surface is 200mm, and the horizontal distance between the surface of the sputtering...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com