Preparation method and application of europium-dysprosium-doped cerium-zirconium solid solution supported rhodium catalyst

A technology of rhodium catalyst and solid solution, which is applied in the field of low-temperature and high-efficiency catalytic combustion to eliminate VOCs, and can solve the problem of high VOCs reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

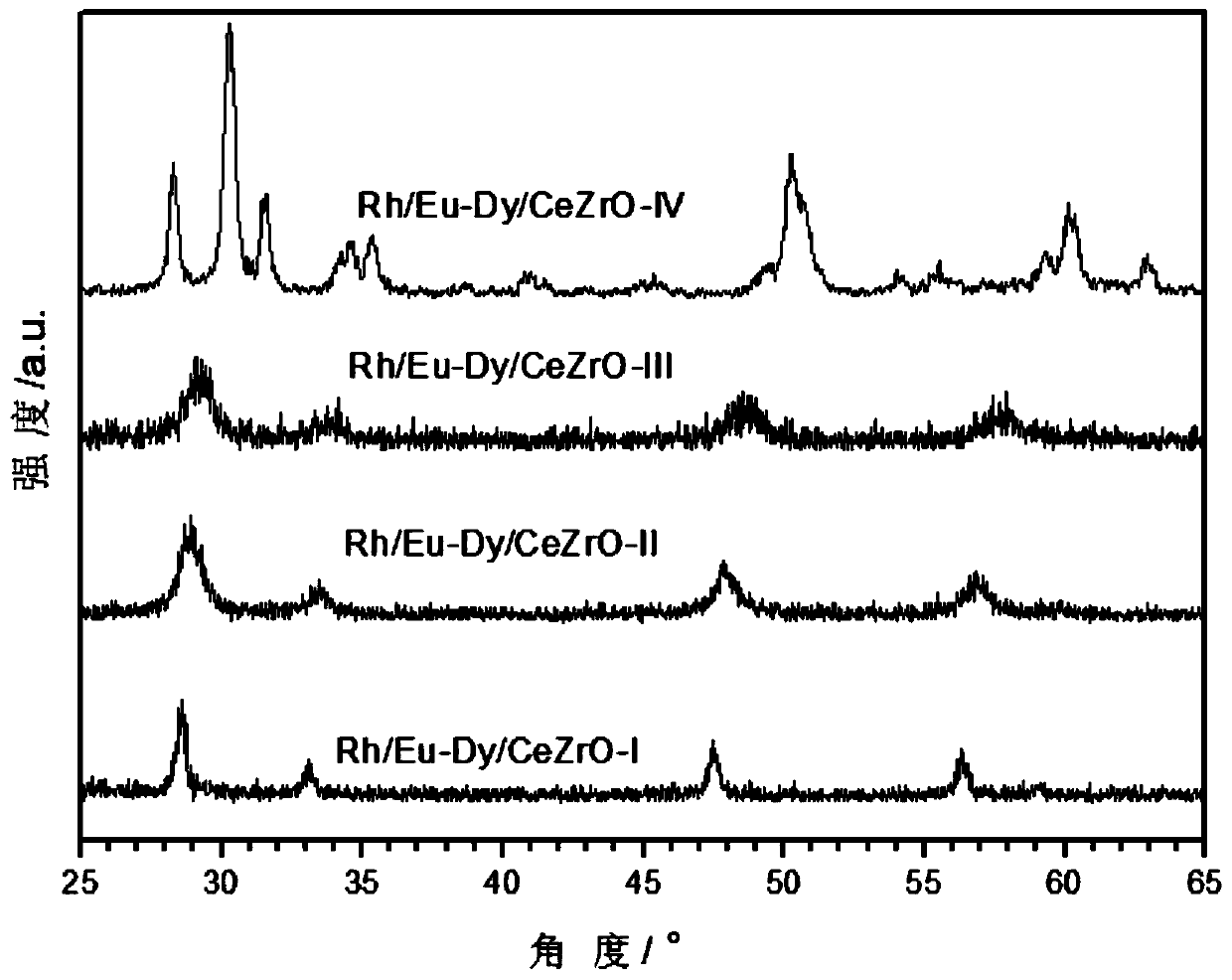

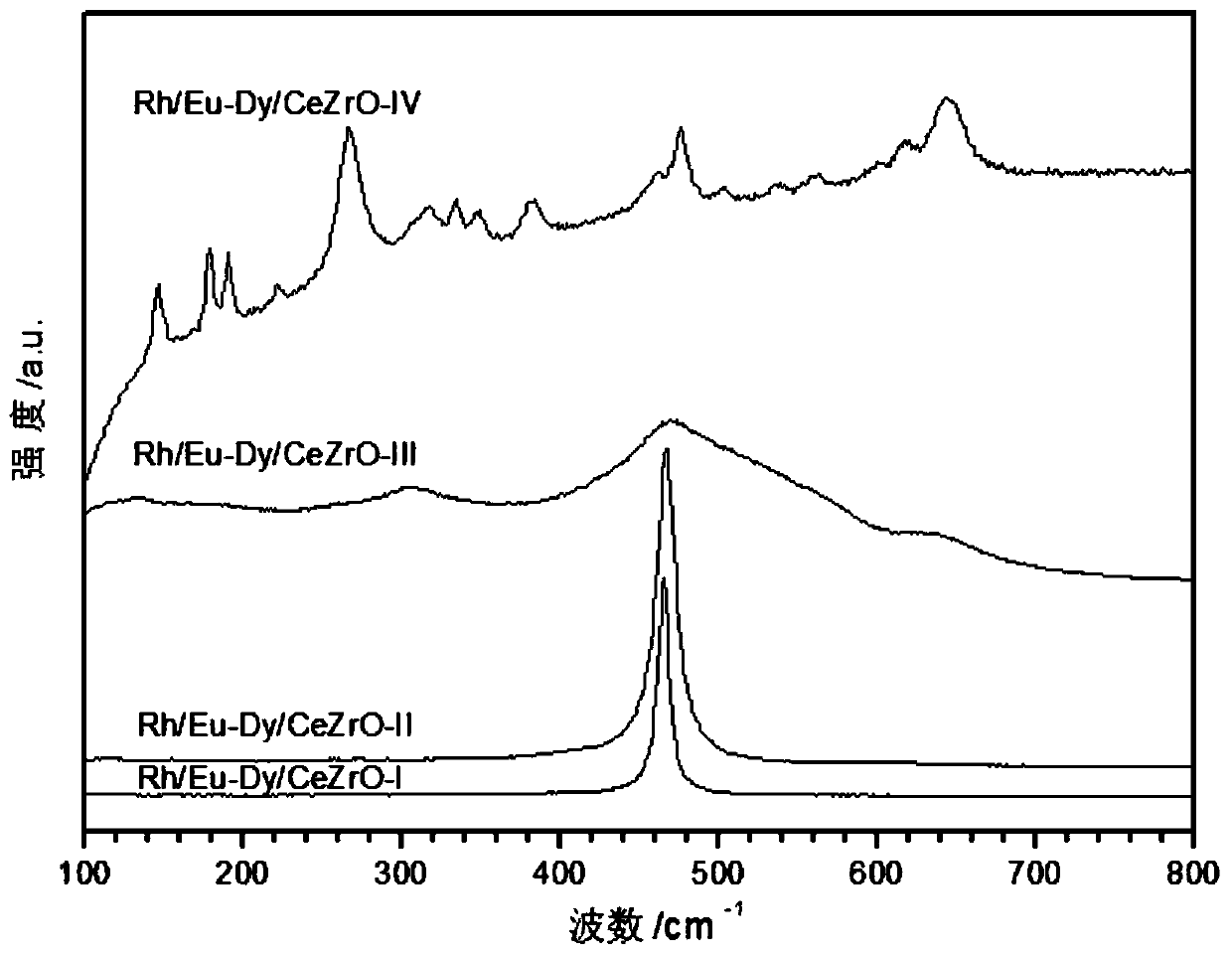

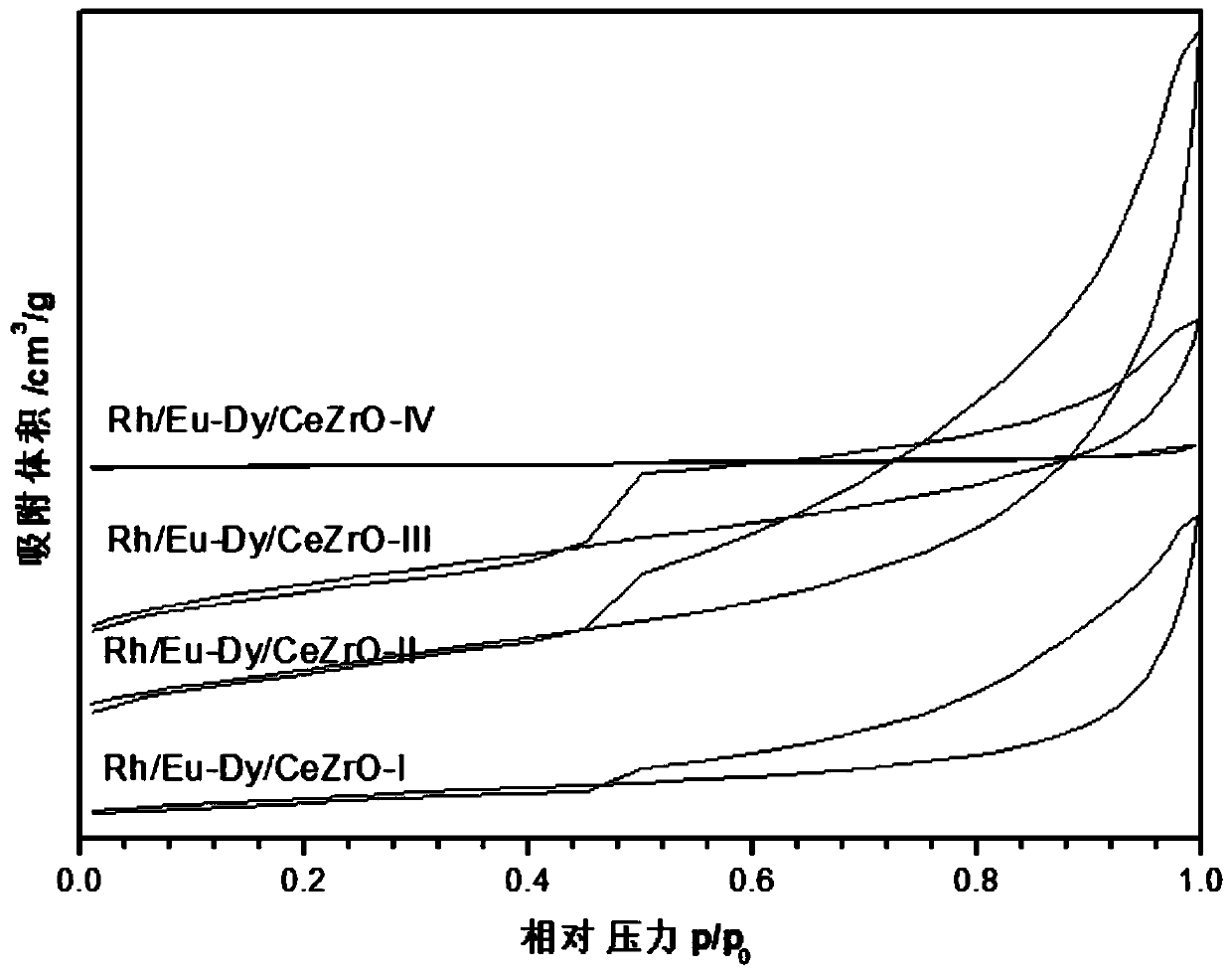

Embodiment 1

[0021] (1) the preparation method of above-mentioned catalyst provided by the present invention, comprises the steps:

[0022] zirconium oxynitrate ZrO(NO 3 ) 2 ·H 2 O and cerium nitrate Ce(NO 3 ) 3 ·6H 2 O was added to 50mL distilled water and stirred to form a mixed solution, the concentration of cerium nitrate solution was 0.05mol / L, n[ZrO(NO 3 )2 ]: n[Ce(NO 3 ) 3 ]=0.1:1.0. In addition, HPMA is added to 20mL of phenolic resin-containing 20wt% ethanol solution and mixed and stirred to form a surfactant solution, wherein HPMA:phenolic resin=0.01mL:1mL, it is added to the above mixed solution of cerium and zirconium to increase the concentration of the solution Dispersion of medium salt. Then 0.5g C-FDU-15 (Yan Meng, Dong Gu, et.al.Angew.Chem.Int.Ed.2005,44,7053–7059) was added to the above mixed solution to form a suspension, wherein Ce(NO 3 ) 3 : C-FDU-15=0.0025-0.005mol: 1g, and at 5W / cm 2 Ultrasonic at the intensity of 1h, reflux at 80°C for 24h, 80°C rotary e...

Embodiment 2

[0027] (1) the preparation method of above-mentioned catalyst provided by the present invention, comprises the steps:

[0028] zirconium oxynitrate ZrO(NO 3 ) 2 ·H 2 O and cerium nitrate Ce(NO 3 ) 3 ·6H 2 O was added to 70mL distilled water and stirred to form a mixed solution, the concentration of cerium nitrate solution was 0.07mol / L, n[ZrO(NO 3 ) 2 ]: n[Ce(NO 3 ) 3 ]=0.5:0.5. In addition, HPMA is added to the 25wt% ethanol solution containing phenolic resin of 30mL and mixed and stirred to form a surfactant solution, wherein HPMA: phenolic resin=0.03mL: 1mL, it is added in the mixed solution of above cerium zirconium, to increase Dispersion of salt in solution. Then 0.7g C-FDU-15 (Yan Meng, Dong Gu, et.al.Angew.Chem.Int.Ed.2005,44,7053–7059) was added to the above mixed solution to form a suspension, wherein Ce(NO 3 ) 3 : C-FDU-15=0.003mol: 1g, and at 5W / cm 2 Ultrasonic at the intensity of 1h, reflux at 80°C for 24h, 80°C rotary evaporation to evaporate the sol...

Embodiment 3

[0033] (1) the preparation method of above-mentioned catalyst provided by the present invention, comprises the steps:

[0034] zirconium oxynitrate ZrO(NO 3 ) 2 ·H 2 O and cerium nitrate Ce(NO 3 ) 3 ·6H 2 O was added to 90mL distilled water and stirred to form a mixed solution, the concentration of cerium nitrate solution was 0.09mol / L, n[ZrO(NO 3 ) 2 ]: n[Ce(NO 3 ) 3 ]=1.0:1.0. In addition, HPMA is added to 40mL of phenolic resin-containing 28wt% ethanol solution and mixed and stirred to form a surfactant solution, wherein HPMA:phenolic resin=0.04mL:1mL, it is added to the above mixed solution of cerium and zirconium to increase the concentration of the solution Dispersion of medium salt. Then 0.9g C-FDU-15 (Yan Meng, Dong Gu, et.al.Angew.Chem.Int.Ed.2005,44,7053–7059) was added to the above mixed solution to form a suspension, wherein Ce(NO 3 ) 3 : C-FDU-15=0.004mol: 1g, and at 9W / cm 2 Ultrasonic at the intensity of 2h, reflux at 90°C for 48h, and evaporate the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com