Device capable of controlling mineral fiber crystal microstructure and controlling method utilizing device

A mineral fiber and microstructure technology, applied in grain processing and other directions, can solve the problems of high proportion of superfine powder and low concentration of particle size distribution, and achieve the effects of accelerating dissociation, improving dissociation characteristics and reducing energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

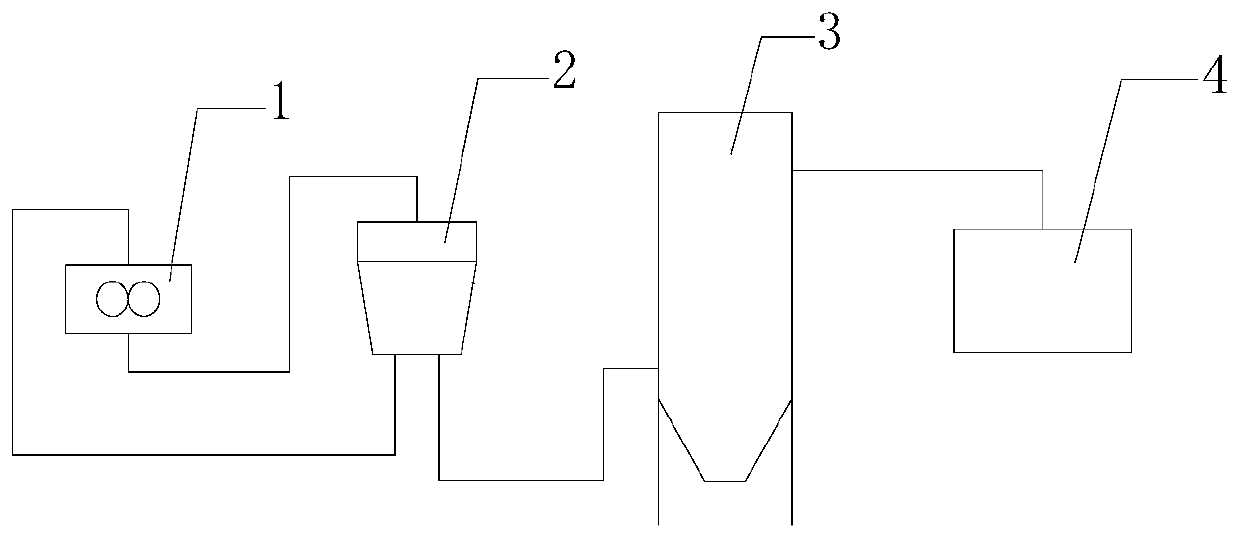

[0029] A device for controlling the fine structure of mineral fiber crystal form, the device includes a roller press 1, a cleavage device 2, a jet mill 3, and a classifier 4;

[0030] The roller surface of the pressing roller of the roller press 1 is a diamond pattern, and the hardness of the diamond pattern is HRC58;

[0031] The discharge port of the roller press 1 is connected with the cleavage device 2;

[0032] The lining of the cleaving device 2 and its cleaving blades are special industrial ceramics with a replaceable structure and no pollution to materials;

[0033] The unqualified product discharge port of the cleavage device 2 is connected with the feed port of the roller press 1;

[0034] The qualified product outlet of described cleavage device 2 is connected with jet mill 3;

[0035] The upper cavity of the jet mill 3 is connected with a classifier 4 .

Embodiment 2

[0037] A method utilizing the controllable mineral fiber crystal structure of the device described in Example 1, said method comprising the steps of:

[0038] S1, coarsely crushing wollastonite raw ore to 50-80mm particles;

[0039] S2, the product obtained in step S1 is subjected to photoelectric beneficiation to remove impurities such as gangue;

[0040] S3, the product obtained in step S2 is transported to the roller press 1, and the pressing device of the roller press 1 applies a pressure of 190MPa to the pressure roller, and the speed difference of the two pressure rollers is 500rpm, and the material is subjected to frictional shear while loading the static pressure. Shear force, the product obtained in step S2 is broken to 0.08-1.20mm;

[0041] S4, the product obtained in step S3 is transported to the cleavage device 2, the rotating speed of the cleavage grading sieve of the cleavage device 2 is 800rpm, and the wollastonite coarse powder greater than 1mm after cleavage ...

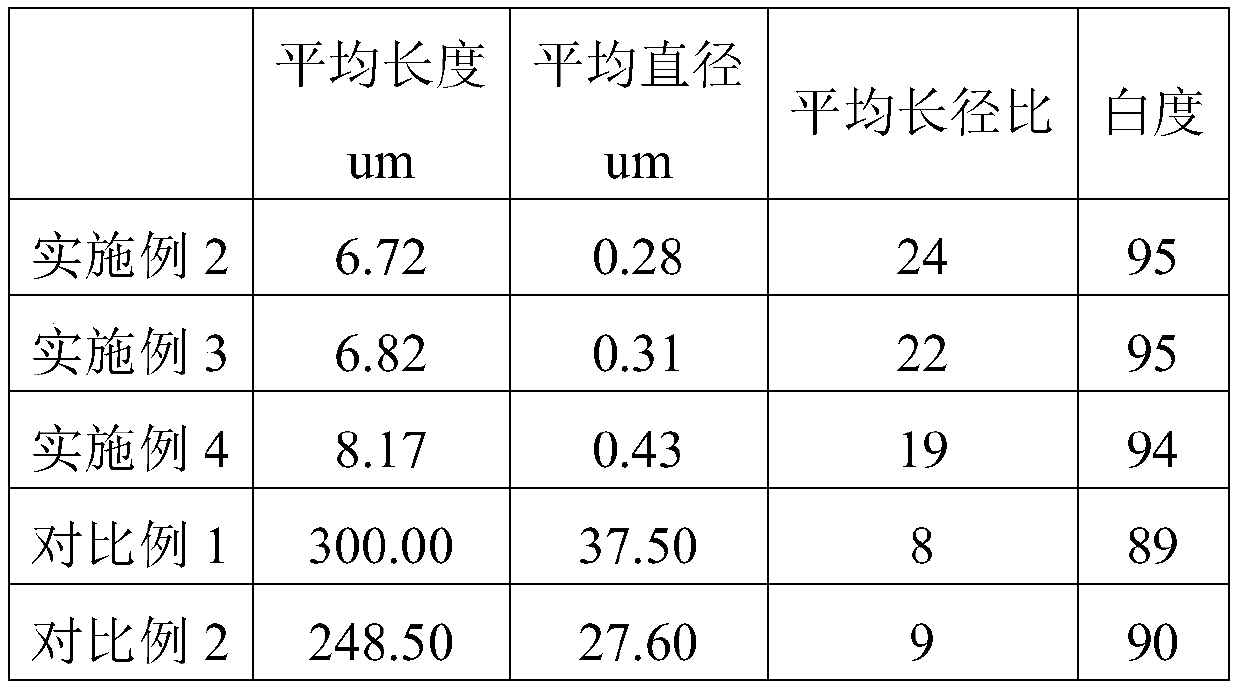

Embodiment 3

[0045] A method utilizing the controllable mineral fiber crystal microstructure of the device described in embodiment 1, the difference from embodiment 2 is:

[0046] S3, the product obtained in step S2 is transported to the roller press 1, and the pressing device of the roller press 1 applies a pressure of 160MPa to the pressure roller, and the speed difference of the two pressure rollers is 200rpm, and the material is subjected to frictional shear while loading the static pressure. Shear force, the product obtained in step S2 is broken to 0.08-1.50mm;

[0047] S4, the product obtained in step S3 is transported to the cleavage device 2, the rotating speed of the cleavage grading sieve of the cleavage device 2 is 800rpm, and the wollastonite coarse powder greater than 1mm after cleavage classification is returned to the roller press 1, and the wollastonite coarse powder less than 1mm is returned to the roller press 1. The wollastonite powder is transported to the jet mill 3 af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com