Liquid nitrogen follow-up cooling additive manufacturing device and method

A technology of additive manufacturing and cooling device, which is applied in the field of additive manufacturing, can solve the problems of unsuitable additive manufacturing structural parts and limited use of space, and achieve the effects of saving waiting cooling time, improving precision, and improving additive quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings.

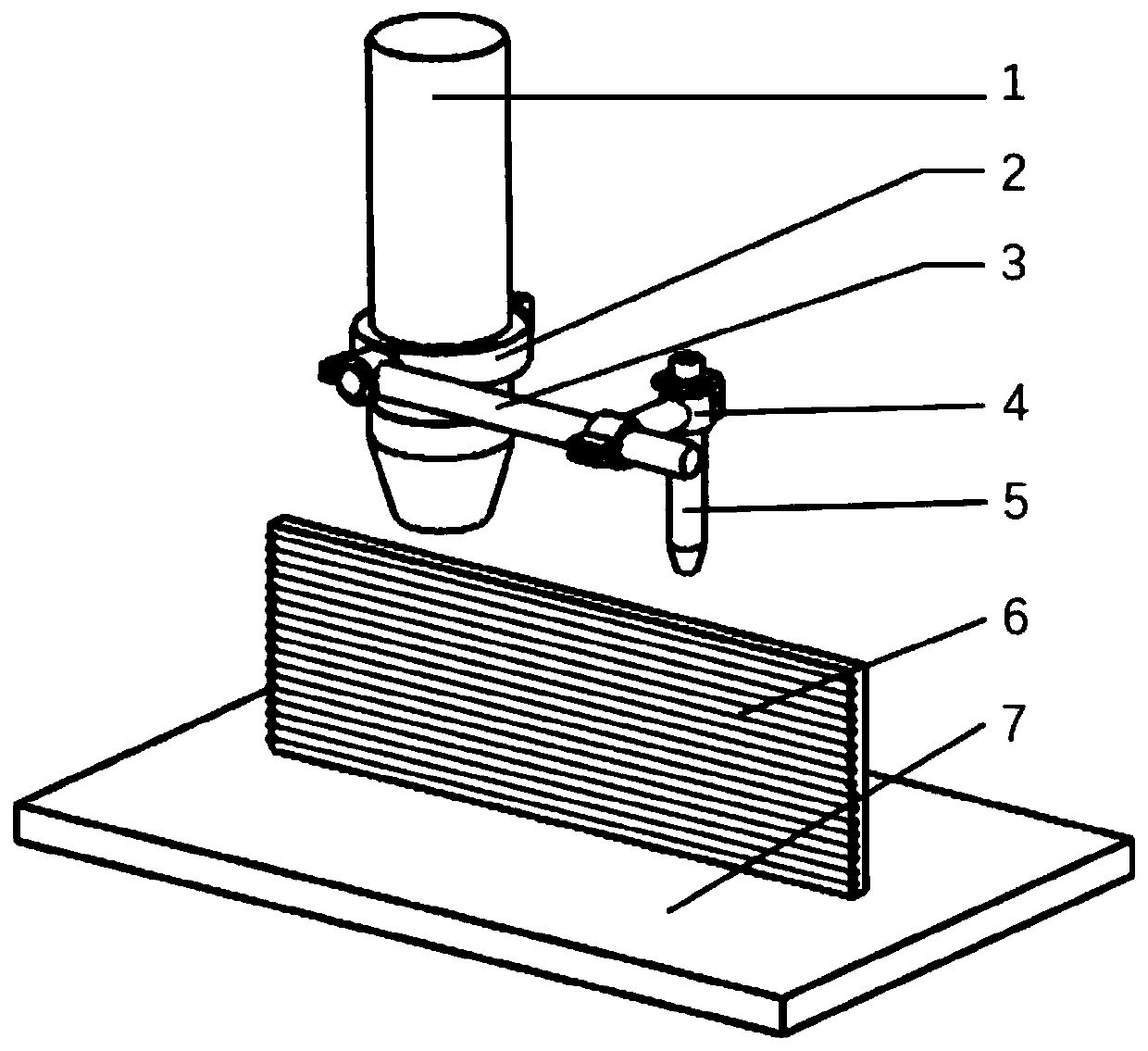

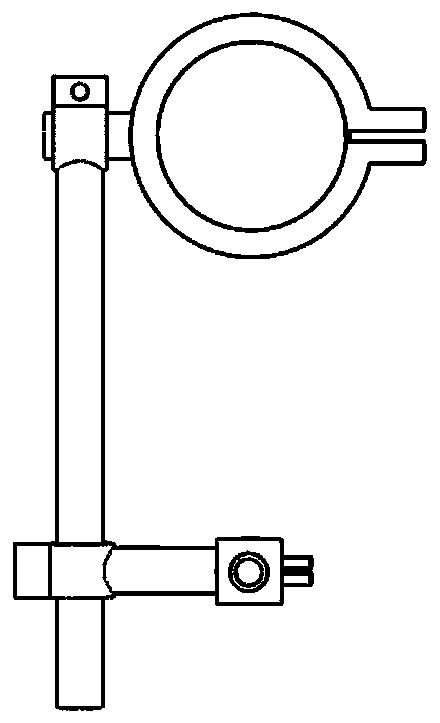

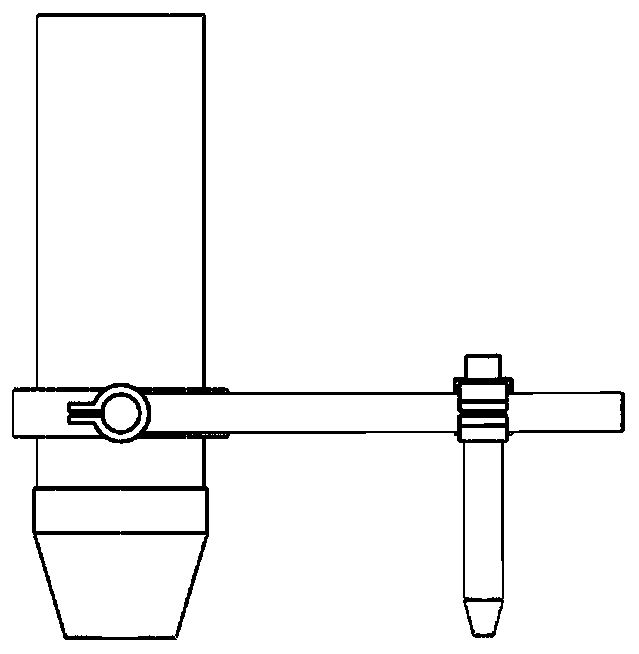

[0042] Such as Figure 1-3 As shown, a liquid nitrogen follow-up cooling additive manufacturing device includes:

[0043] 2-Welding torch tip clamp, which is a circular clamp, used to clamp the welding torch tip; 3-Connection mechanism, a cylinder with a circular clamp at one end, used to connect the welding torch tip clamp and nozzle clamp; 4- The nozzle clamp is a cylinder with circular clamps at both ends, which is used to clamp the connection mechanism and the nozzle; 5-nozzle, which is used to connect the liquid nitrogen conduit.

[0044] It proceeds as follows:

[0045] Using CMT additive manufacturing system, the welding wire used is 316L stainless steel wire with a diameter of 1.0mm; the substrate is 6mm thick 304 stainless steel substrate; the shielding gas is argon oxygen: 98.5% Ar+1.5% O2;

[0046] Step 1: According to the size and shape of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com