Flexible conductive MXene-based foam and preparation method thereof

A flexible conductive and foam technology, which is applied in the field of two-dimensional metal carbide-based flexible conductive foam materials and its preparation, can solve the problems of poor mechanical and electrical properties and application performance, and achieve rich pores, high reactivity, and high specific surface area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

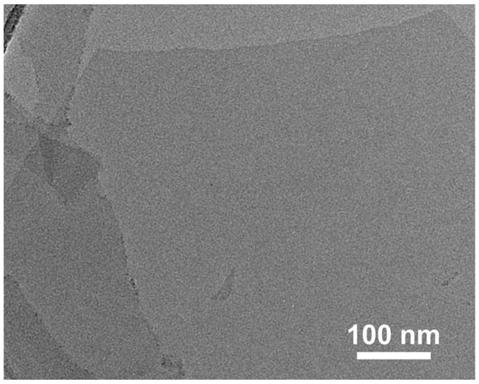

[0027] 1g LiF was slowly added to 20mL 9M HCl solution, followed by 1g Ti 3 AlC 2 MAX powder (>400 mesh) was dispersed in the above mixed solution, and the suspension was placed in a water bath environment at 35°C and vigorously stirred at a speed of 500rpm for 24 hours. Then centrifuge the suspension at 3500rpm for 5 minutes, pour off the upper layer of acidic liquid, redisperse the lower layer of centrifuge into 40mL deionized water, mix well and centrifuge at 3500rpm for 5 minutes, repeat washing and centrifugation 4 times until the centrifuge The pH is around 6. Finally, the obtained centrifuge was dispersed into 20mL deionized water again, shaken vigorously for 20 minutes, and centrifuged at a speed of 1500rpm for 60 minutes to obtain the upper suspension, denoted as Ti 3 C 2 MXene, its concentration is about 35mg / mL. figure 1 Its transmission electron microscope picture, can find: the Ti of gained Ti prepared by this method 3 C 2 MXene materials have an ultrathin n...

Embodiment 2

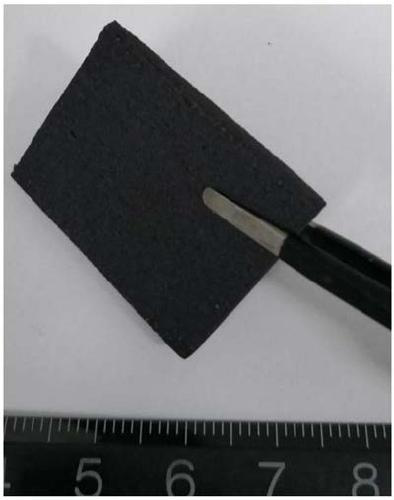

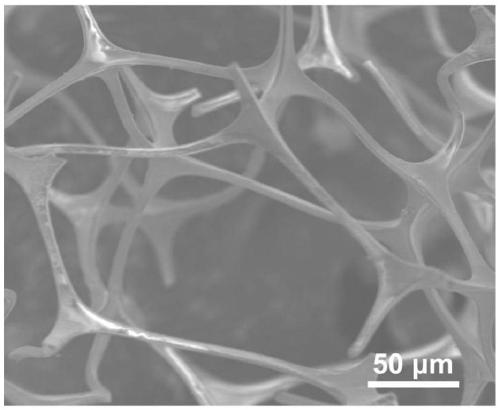

[0029] 1g Ti 3 AlC 2(>400 mesh) and 120ml 40% HF acid shaking reaction for 72 hours, centrifuged at 6000rpm for 5 minutes, poured the supernatant centrifugate, mixed the centrifuged product with water and continued to centrifuge until the pH value of the centrifuged solution was ~6, and placed the obtained centrifuged product in 60 After vacuum drying at ℃ for 24 hours, an accordion-shaped multilayer Ti can be obtained 3 C 2 MXene. Take 0.3g multilayer Ti 3 C 2 MXene was added to 5mL DMSO, stirred at room temperature at 300rpm for 18 hours, and centrifuged at 5000rpm for 5 minutes to obtain a sediment. 3 C 2 The mass ratio of MXene to deionized water is 1:500, add deionized water, ultrasonically treat the suspension for 6 hours, centrifuge at 3500rpm for 5 minutes, collect the upper centrifugate, and obtain a few-layer Ti 3 C 2 MXene nanosheet dispersion. Cut polyurethane foam to size and soak completely in Ti 3 C 2 Squeeze out the excess liquid in the MXene dispers...

Embodiment 3

[0031] 1g Ti 3 SiC 2 (>400 mesh) and 60% HF acid shaking reaction for 72 hours, Ti 3 SiC 2 The mass ratio of MAX to HF acid is 1:140, centrifuge at 6000rpm for 5 minutes, pour out the supernatant centrifugate, add water to mix and centrifuge until the pH of the centrifugate is ~6, and place the obtained centrifuge at 60°C for 24 hours to obtain an accordion multilayer Ti 3 C 2 MXene. Take 0.3g multilayer Ti 3 C 2 MXene added to DMSO, Ti 3 C 2 The mass ratio of MXene to DMSO is 0.5:1. Stir at room temperature at 300rpm for 18 hours, and centrifuge at 5000rpm for 5 minutes to obtain a sediment. 3 C 2 The mass ratio of MXene to deionized water is 1:500, add deionized water, ultrasonically treat the suspension for 6 hours, centrifuge at 3500rpm for 5 minutes, collect the upper centrifugate, and obtain a few-layer Ti 3 C 2 MXene nanosheet dispersion. Cut PVC foam to size and completely soak in Ti 3 C 2 Squeeze out the excess liquid in the MXene dispersion, place it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com