Fullerene-like carbon-based composite film and preparation method thereof

A fullerene-like, composite film technology, applied in gaseous chemical plating, metal material coating technology, photovoltaic power generation, etc. Low controllability and other issues, to achieve the effect of high hardness, simple equipment, and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The specific steps for preparing fullerene-like carbon-based composite films on single crystal Si are as follows:

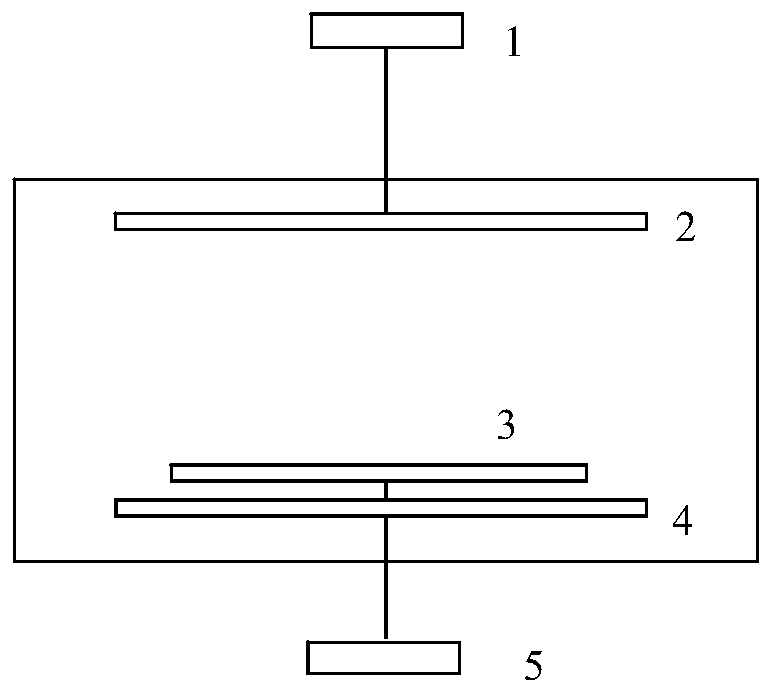

[0027] (1) With single crystal Si(100) as the substrate, firstly clean it ultrasonically in acetone solution for 5 minutes, then clean it in alcohol solution for 5 minutes, then dry it with a hair dryer and put it on the working table of the coating room (such as figure 1 shown); evacuate the coating chamber so that the vacuum degree is lower than 3×10 -3 Pa, then pass 10Pa of argon gas into the coating chamber, and apply a pulse bias voltage of -800V to the substrate, with a duty ratio of 0.4 and a frequency of 20kHz, and etch and clean the substrate surface for 20 minutes;

[0028] (2) Methane and argon are passed into the coating chamber at a flow ratio of 1:2, so that the air pressure of the coating chamber is 10Pa; the upper plate in the coating chamber is connected with a radio frequency power supply (such as figure 1 shown), the RF power gradually ...

Embodiment 2

[0034] The specific steps for preparing fullerene-like carbon-based composite films on single crystal Si are as follows:

[0035] (1) With single crystal Si(100) as the substrate, firstly clean it ultrasonically in acetone solution for 5 minutes, then clean it in alcohol solution for 5 minutes, then dry it with a hair dryer and put it on the working table of the coating room (such as figure 1 shown); evacuate the coating chamber so that the vacuum degree is lower than 3×10 -3 Pa, then pass 15Pa of argon gas into the coating chamber, and apply a pulse bias voltage of -1200V to the substrate, with a duty cycle of 0.7 and a frequency of 40kHz, and etch and clean the substrate surface for 30 minutes;

[0036] (2) Methane and argon are passed into the coating chamber at a flow ratio of 1:1, so that the air pressure of the coating chamber is 15Pa; the upper plate in the coating chamber is connected with a radio frequency power supply (such as figure 1 shown), the RF power gradually...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com