PDC (Polycrystalline Diamond Compact) drilling head with dynamic stress interference principle

A dynamic stress, drill bit technology, applied in mining engineering, oil and gas drilling engineering, tunnel engineering, geological drilling fields, can solve the problems of short working life of the drill bit, low rock breaking efficiency, poor penetration ability of PDC teeth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

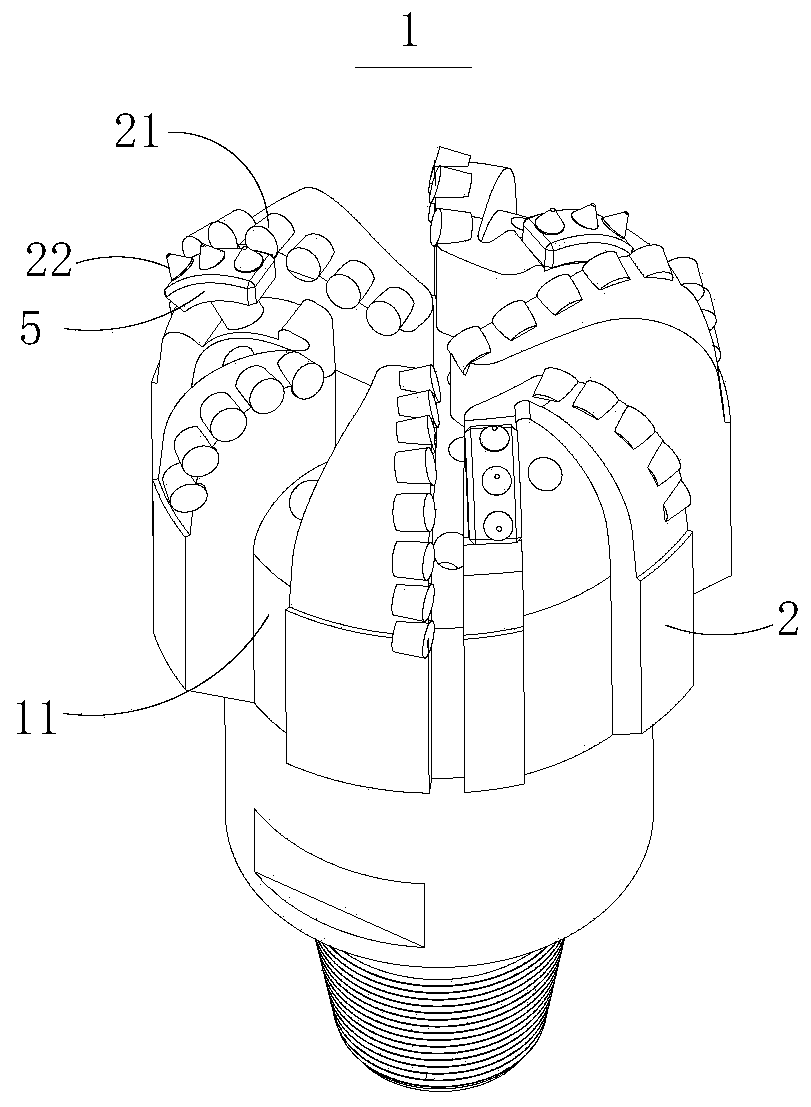

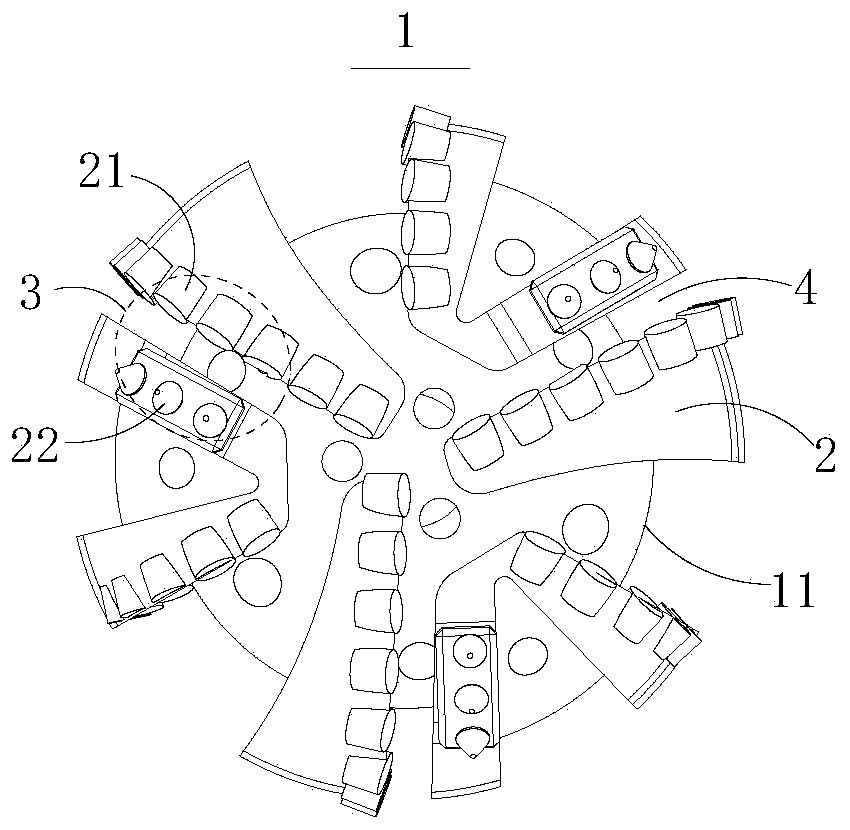

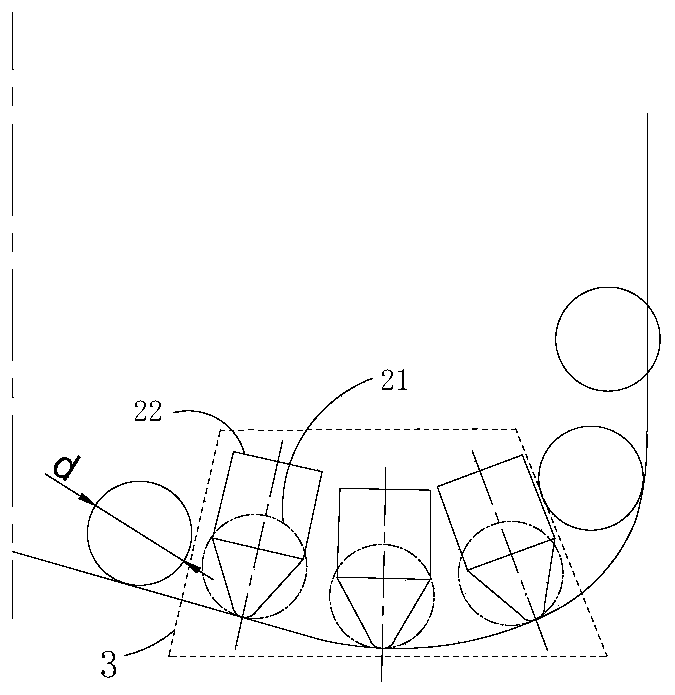

[0031] see Figure 1-Figure 6 , the embodiment of the present invention provides a PDC drill bit 1 with the principle of dynamic stress interference. The PDC drill bit includes a drill body 1 and at least two blades 2. The blades 2 are fixedly connected to or integrally formed with the drill body 1. The drill bit 1 is provided with a mixed cutting unit 3 composed of PDC teeth 21 and impact teeth 22. , the PDC teeth 21 and the impact teeth 22 in the hybrid cutting unit 3 are respectively arranged on two adjacent blades 2; the impact teeth 22 can produce impact motion; in the hybrid cutting unit 3, the PDC teeth 21 and the impact teeth 22 The positional relationship is configured such that in the circumferential direction formed by the rotation of the drill bit 1, the PDC teeth 21 are arranged behind the impact teeth 22, and the range of the distance D between the PDC teeth 21 and the impact teeth 22 is: 4d≥D≥d, d is the diameter of the PDC tooth.

[0032] The tooth form of im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com