Layered porous material for adsorbing and separating allylene and propylene and preparation method and application thereof

A propyne, propyne, adsorption separation technology, applied in the field of chemical engineering, can solve problems such as the inability to realize the adsorption of propyne and exclusion of propyne, and achieve the effects of good industrial application prospects, large adsorption capacity, and complete crystal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] 10mL containing 0.25mmol Cu (BF 4 ) 2 ·H 2 O, (NH 4 ) 2 GeF 6 The aqueous solution of the solution was added dropwise to 10 mL of methanol solution containing 0.5 mmol 4,4-dipyridine sulfide, and then 20 mL of the mixed solution in which metal salts, inorganic anions and organic ligands were dissolved was placed in an oven at 80 ° C for 48 h. After the reaction, blue crystals were obtained, and the obtained product was filtered, washed with methanol and left to stand for 3 days, and the methanol was replaced every other day during the process, and then activated by vacuum at 100°C for 24 hours to obtain the GeFSIX-dps-Cu layered porous material.

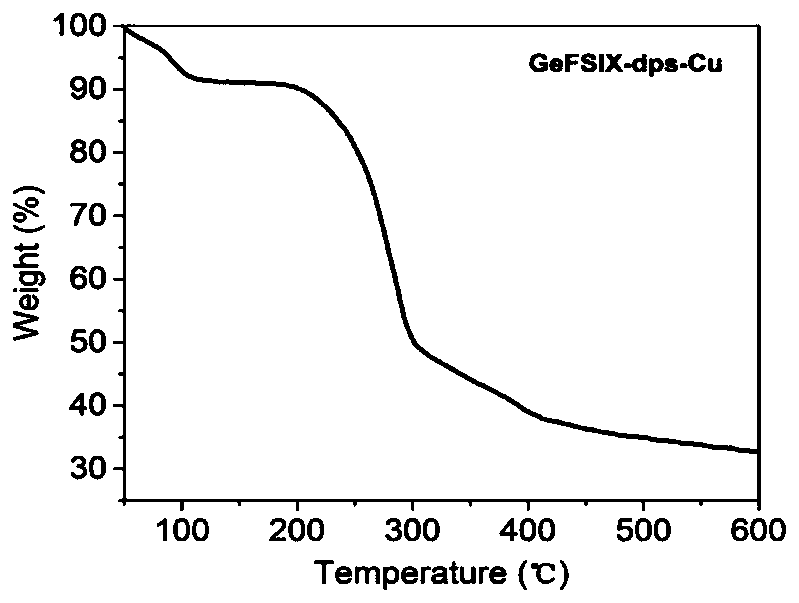

[0061] The thermogravimetric curve of the GeFSIX-dps-Cu layered porous material obtained in the present embodiment is as follows figure 1 As shown, it has high thermal stability.

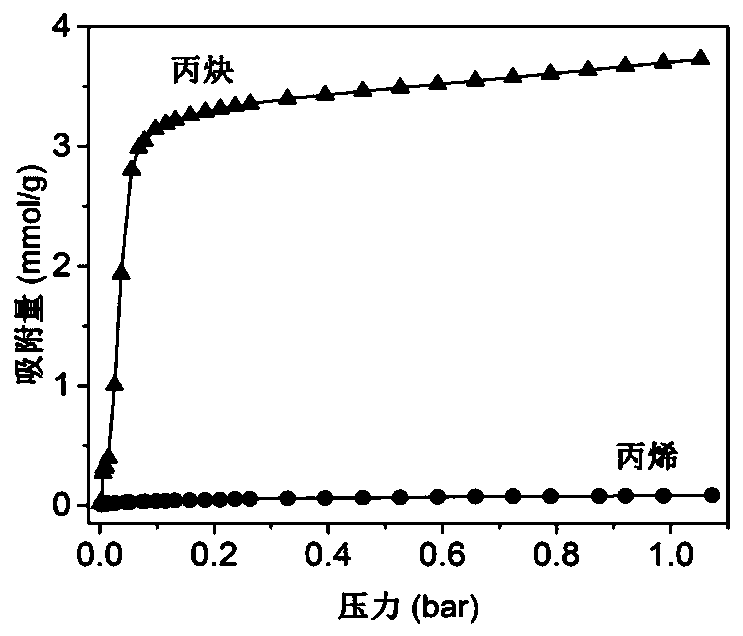

[0062] The adsorption isotherm of the GeFSIX-dps-Cu layered porous material obtained in this embodiment to propargyl propene at 298K is as fo...

Embodiment 2

[0065] 10mL containing 0.25mmol ZnGeF 6 10 mL of methanol solution containing 0.5 mmol 4,4-dipyridine sulfide dropwise, and then 20 mL of the mixed solution in which metal salts, inorganic anions and organic ligands were dissolved was reacted at room temperature for 72 hours. After the reaction, white crystals were obtained. The obtained product was filtered, washed with methanol and left to stand for 3 days, and the methanol was replaced every other day during the process. After that, it was activated under vacuum for 24 hours at room temperature to obtain GeFSIX-dps-Zn layered porous material.

[0066] The thermogravimetric curve of the GeFSIX-dps-Zn layered porous material obtained in the present embodiment is as follows Figure 4 As shown, it has high thermal stability.

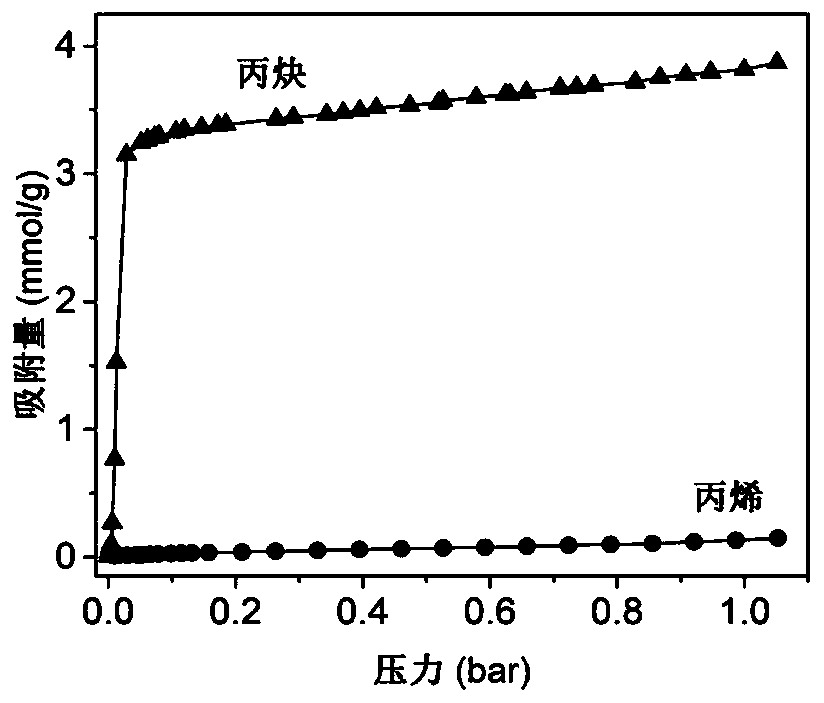

[0067] The adsorption isotherm of the GeFSIX-dps-Zn layered porous material obtained in this example to propargyl propene at 298K is as follows Figure 5 As shown, the material has a higher propyne adso...

Embodiment 3

[0070] 10mL containing 0.25mmol Cu (BF 4 ) 2 ·H 2 O, (NH 4 ) 2 TiF 6 The aqueous solution of the solution was added dropwise to 10 mL of methanol solution containing 0.5 mmol 4,4-dipyridine sulfide, and then 20 mL of the mixed solution in which metal salts, inorganic anions and organic ligands were dissolved was placed in an oven at 80 ° C for 48 h. After the reaction, blue crystals were obtained, and the obtained product was filtered, washed with methanol and left to stand for 3 days, and the methanol was replaced every other day during the process, and then activated by vacuum at 100°C for 24 hours to obtain TiFSIX-dps-Cu layered porous material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com