Manufacturing method of functional food packaging material with antibacterial ability

A technology for functional food and packaging materials, applied in packaging, household packaging, packaged food, etc., can solve the problems of affecting the inherent taste of food, imperfect effect, harmful preservatives, etc., to improve food storage capacity, enhance antibacterial and anti- Oxidative activity, the effect of maintaining freshness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1. Manufacture of food packaging materials.

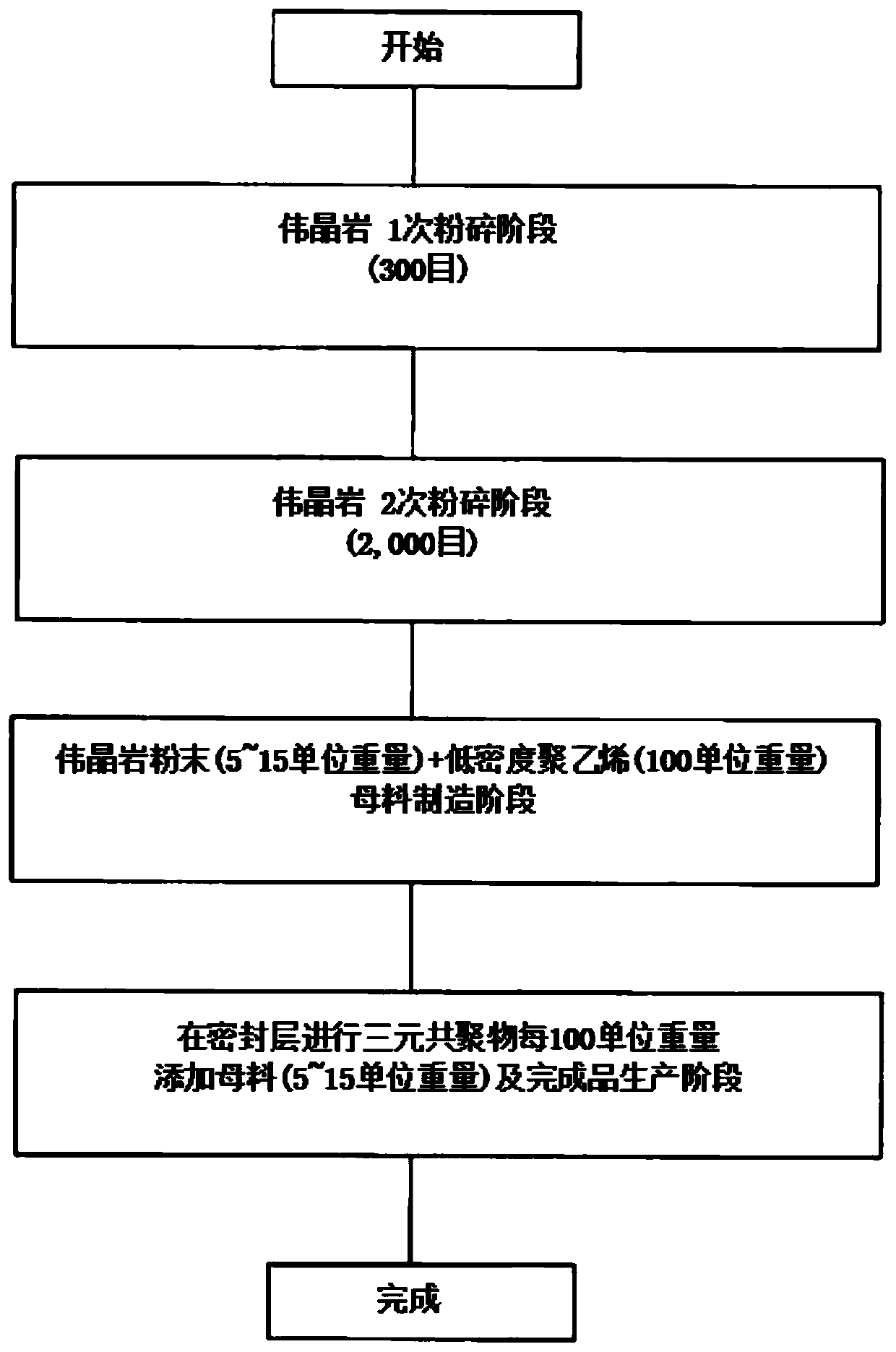

[0019] In this embodiment, pegmatite is used to manufacture food packaging materials. (refer to figure 1 )

[0020] First prepare 5 kilograms of natural mineral massive pegmatite (less than 1 centimeter in diameter) and low-density polyethylene resin that will be added in the food packaging material. Then, the primary pulverization of the 350-mesh powder particles was performed on the above-mentioned massive pegmatite.

[0021] The above-mentioned pulverized pegmatite powder particles are subjected to secondary processing with a size of about 2,500 mesh through high-performance pulverization equipment using air high-speed vortex or high-frequency pressure change vibration. The reason why it is processed into 2,500 meshes is to take into account the wear and tear of the machine that may occur when printing the finished product and the transparency of the finished product.

[0022] The prepared 2,500-mesh pegmatite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com