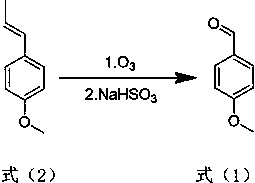

Method for preparing anisaldehyde through micro-channel continuous ozone oxidation

A technology of ozone oxidation and anisaldehyde, applied in the field of chemical application, can solve the problems such as unreported production of anisaldehyde, achieve the effects of low cost, few by-products, and avoiding energy consumption and human consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

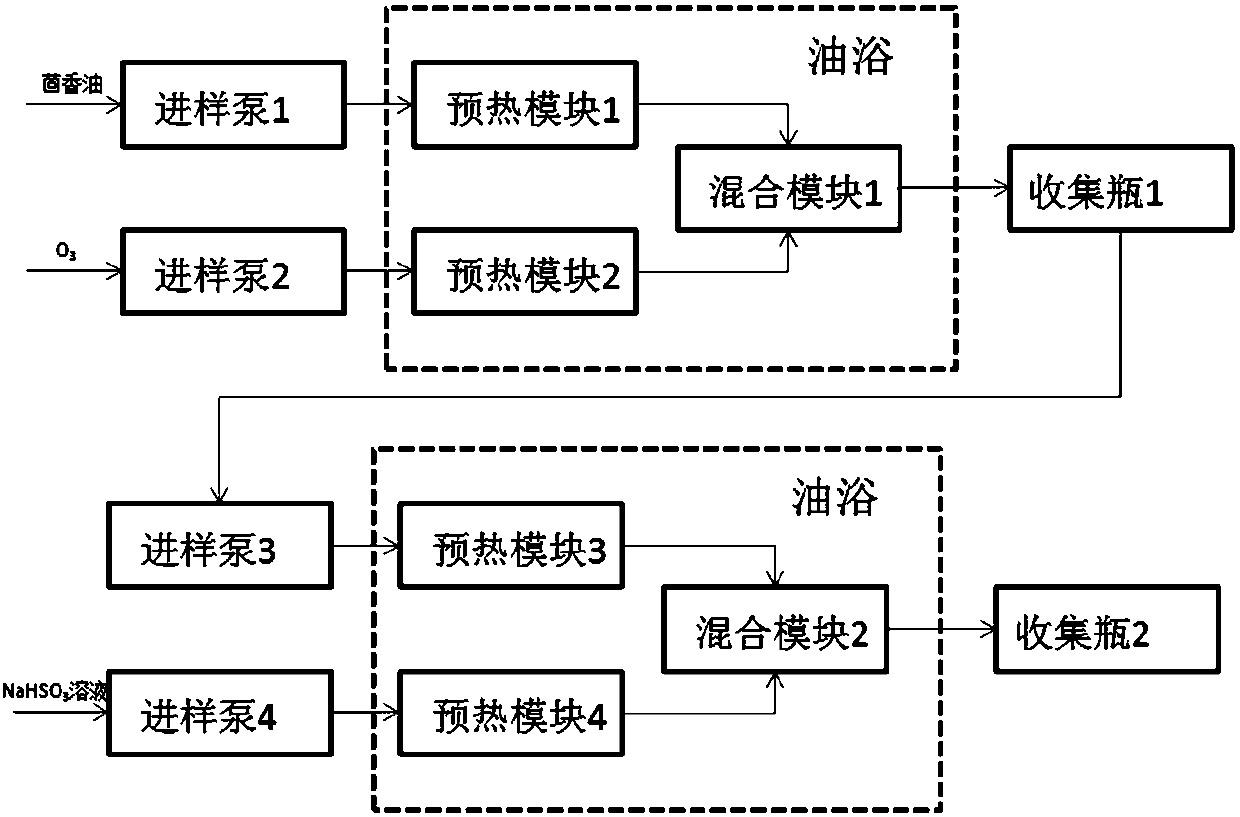

[0030] Embodiment 1: Take 3.08g of fennel oil (90% anethole content) and dissolve it in 10g of cyclohexane; the fennel oil solution is passed into the sampling pump 1 and sent to the preheating module 1 in the microchannel reactor; ozone The generator uses oxygen as the gas source to prepare ozone, and the concentration of the ozone generator is set to 60%. The ozone generated by the ozone generator is passed into the sampling pump 2 and sent to the preheating module 2 in the first microchannel reactor; the control of the sampling pump 1 and the flow rate of the injection pump 2 is 1mL / min, the microchannel oil bath temperature is room temperature; the fennel oil solution in the preheating module 1 enters the mixing module 1 through the pipeline after preheating, and the ozone in the preheating module 2 is preheated. After heating, it enters the mixing module 1 through the pipeline, and the two are mixed to start the oxidation reaction; the time for mixing to flow through the m...

Embodiment 2

[0031] Embodiment 2: Get 3.08g of fennel oil (90% anethole content) and dissolve it in 10g of cyclohexane; the fennel oil solution is passed into the sampling pump 1 and sent to the preheating module 1 in the microchannel reactor; ozone The generator uses oxygen as the gas source to prepare ozone, and the concentration of the ozone generator is set to 60%. The ozone generated by the ozone generator is passed into the sampling pump 2 and sent to the preheating module 2 in the first microchannel reactor; the control of the sampling pump 1 and the flow rate of the injection pump 2 is 1mL / min, the temperature of the microchannel oil bath is -20°C; the fennel oil solution in the preheating module 1 enters the mixing module 1 through the pipeline after preheating; After ozone is preheated, it enters the mixing module 1 through the pipeline, and the two are mixed to start the reaction; the time for mixing to flow through the microchannel reactor is about 20 minutes; the reacted mixed ...

Embodiment 3

[0032] Embodiment 3: Control the flow rate of the sampling pump 1 and the sampling pump 2 to be 0.5mL / min, and the other conditions and procedures are the same as in the embodiment 1. 2.26 g of anisaldehyde was obtained with a yield of 88.7% (calculated by anethole).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com