Special flour for steamed buns and preparation method of special flour for steamed buns

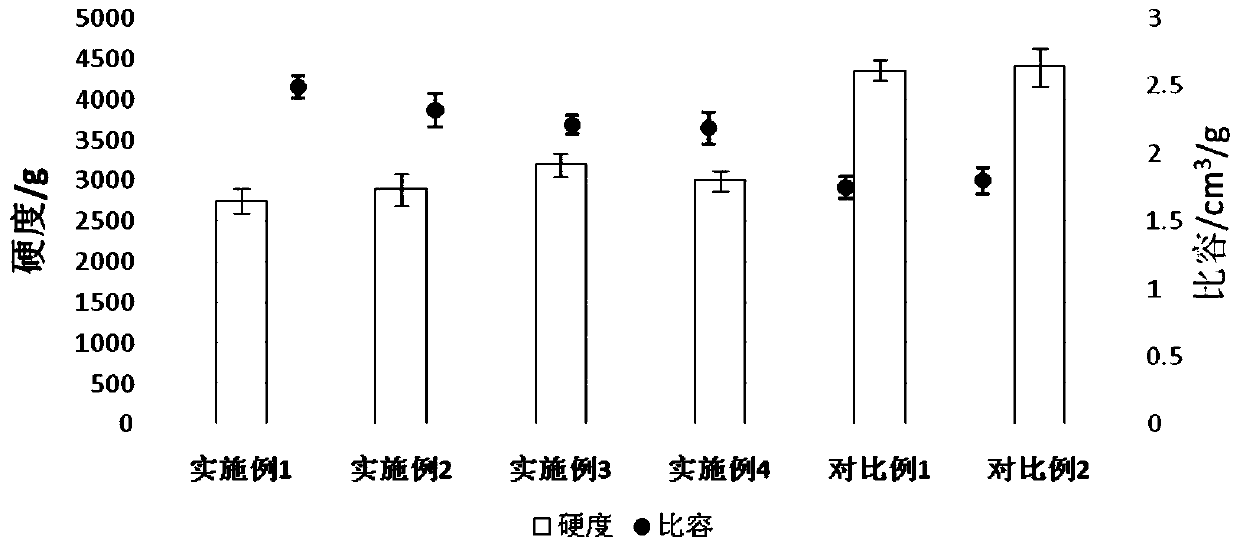

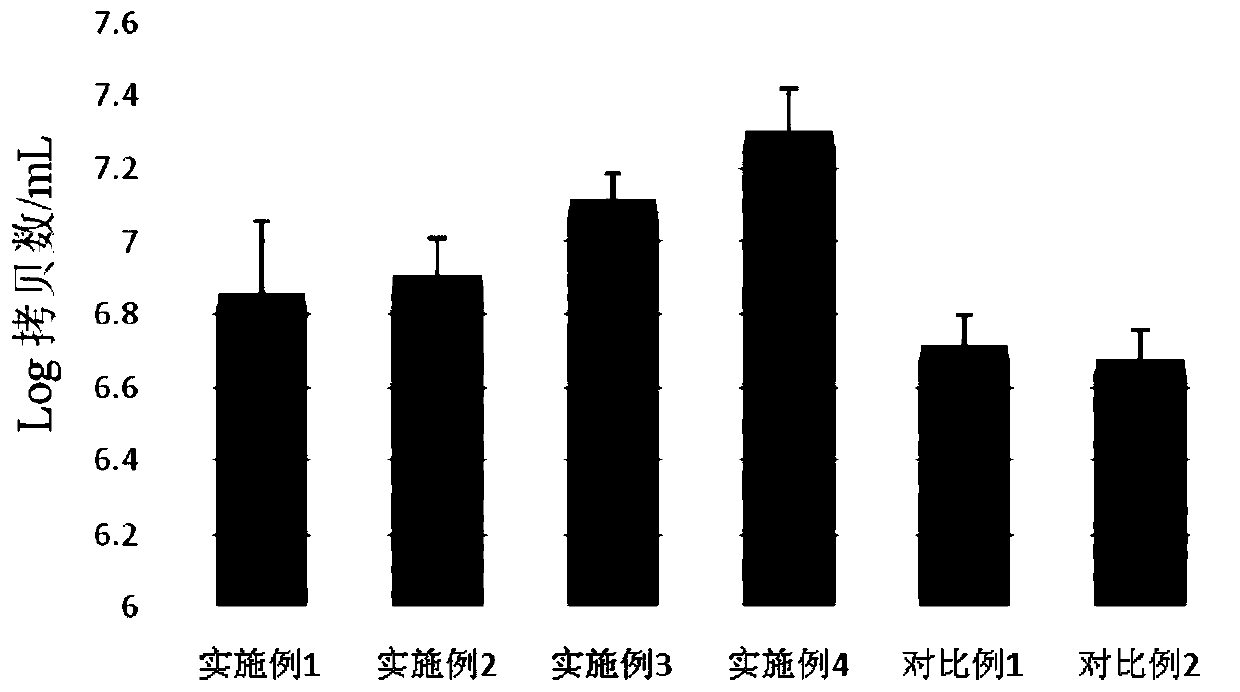

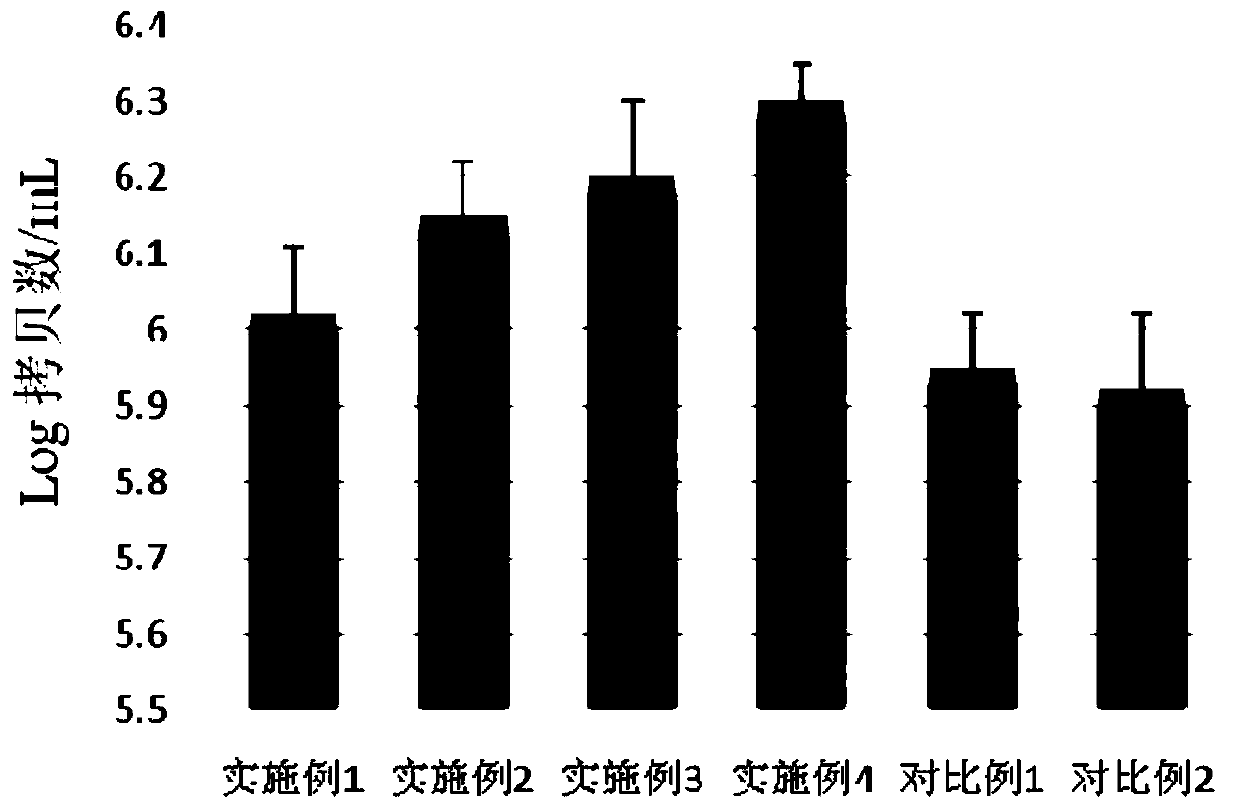

A technology for special flour and steamed bread, which is applied in the field of steamed bread special flour and its preparation, which can solve the problems of decreased palatability, influence on the consumption of aleurone steamed bread, and smaller volume, and achieve rich nutrition, good product flavor and taste, and excellent processing performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] Another aspect of the present disclosure provides a preparation method of special flour for steamed bread, the method comprising the following steps:

[0031] S1, carry out stabilization treatment to wheat aleurone layer powder, obtain the wheat aleurone layer powder after stabilization treatment; Described stabilization treatment is to utilize turbine thin-layer drying system to carry out dry heat treatment to described wheat aleurone layer powder;

[0032] S2, compounding the stabilized wheat aleurone layer powder and common flour to obtain compound flour; the common flour is medium-gluten flour and / or high-gluten flour;

[0033] S3. Add a biological enzyme preparation to the compound powder; the biological enzyme preparation contains at least one of single glucose oxidase, pentosanase and fungal α-amylase.

[0034] According to the method provided by the present disclosure, the stabilization treatment of the wheat aleurone layer is realized by using the turbine thin-...

Embodiment 1

[0042] After the freshly prepared wheat aleurone layer powder is sent to the heating tank of the turbine thin-layer drying system, a dynamic thin layer is formed on the inner wall of the container by means of strong eddy currents, and it is attached to the cylindrical inner surface of the cylinder and moves continuously until it is moved into the tank. At the discharge port, the average temperature of the inner wall of the tank is 180°C, and the cumulative residence time of the material in the tank is 30s. After the powder is cooled, the stabilized wheat aleurone layer powder sample is obtained.

[0043] The above-mentioned stabilized wheat aleurone layer powder and medium-gluten flour are compounded in a mass ratio of 1:5, and then based on the mass of compounded powder, 45mg / kg glucose oxidase, 60mg / kg pentosanase, 10 mg / kg of fungal α-amylase to obtain the special flour for steamed bread in this example.

Embodiment 2

[0045] The freshly prepared wheat aleurone layer powder is impregnated by spray method, and the amount of water added is 6% of the mass of the powder. After the impregnated material is sent to the heating tank of the turbine thin-layer drying system, it forms on the inner wall of the container by strong eddy currents. The dynamic thin layer is attached to the cylindrical inner surface of the cylinder and moves continuously until it is moved into the discharge port of the tank. The average temperature of the inner wall of the tank is 210 °C, and the cumulative residence time of the material in the tank is 45s. After the powder is cooled The stabilized wheat aleurone layer powder sample was obtained.

[0046] The above-mentioned stabilized wheat aleurone layer powder and medium-gluten flour are compounded in a mass ratio of 1:4, and then based on the mass of compounded powder, 80 mg / kg glucose oxidase and 120 mg / kg pentosanase are added. The special flour for steamed bread in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com