Full-biodegradable toughening injection molding master batch and processing technology thereof

A processing technology, all-biological technology, applied in the field of injection masterbatch, can solve the problems of inability to meet production requirements, lack of flexibility and elasticity, low self-strength, etc., and achieve simple and controllable processing technology, low cost, and improved dispersibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

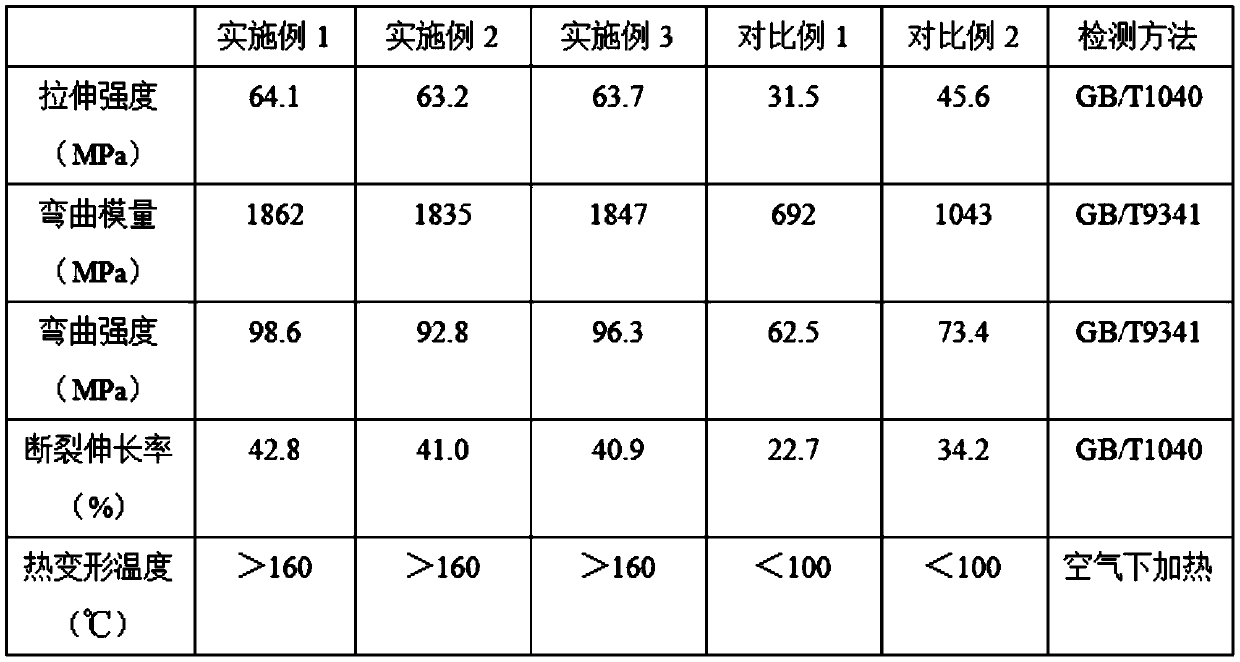

Examples

Embodiment 1

[0037] A fully biodegradable and toughened injection masterbatch, made from the following raw materials in parts by weight:

[0038] 100 parts of modified polylactic acid, 10 parts of modified palygorskite, 6 parts of cicada shell, 8 parts of polybutylene succinate, and 2 parts of talcum powder.

[0039] The modified polylactic acid is obtained by modifying polylactic acid with butyl acrylate, trimethylolpropane triacrylate, and tert-butyl peroxybenzoate;

[0040] The modified palygorskite is obtained by purifying and modifying palygorskite.

[0041] The steps of palygorskite purification are as follows: Weigh the palygorskite powder with a particle size of 50-100 μm, add it to an ethanol solution with a mass concentration of 50-60%, ultrasonicate for 1-2 hours, filter the solid matter, and dry , to obtain palygorskite purified product;

[0042] Among them, the solid-to-liquid ratio of palygorskite powder to ethanol solution is 1:30-50.

[0043] The modified steps of palygo...

Embodiment 2

[0062] A fully biodegradable and toughened injection masterbatch, made from the following raw materials in parts by weight:

[0063] 100 parts of modified polylactic acid, 3 parts of modified palygorskite, 1 part of cicada shell, 5 parts of polybutylene succinate, 1 part of talcum powder;

[0064] The modified polylactic acid is obtained by modifying polylactic acid with butyl acrylate, trimethylolpropane triacrylate, and tert-butyl peroxybenzoate;

[0065] The modified palygorskite is obtained by purifying and modifying palygorskite.

[0066] The steps of palygorskite purification are as follows: Weigh the palygorskite powder with a particle size of 50-100 μm, add it to an ethanol solution with a mass concentration of 50-60%, ultrasonicate for 1-2 hours, filter the solid matter, and dry , to obtain palygorskite purified product;

[0067] Among them, the solid-to-liquid ratio of palygorskite powder to ethanol solution is 1:30-50.

[0068] The modified steps of palygorskite ...

Embodiment 3

[0087] A fully biodegradable and toughened injection masterbatch, made from the following raw materials in parts by weight:

[0088] 100 parts of modified polylactic acid, 15 parts of modified palygorskite, 10 parts of cicada shell, 10 parts of polybutylene succinate, 3 parts of talcum powder;

[0089] The modified polylactic acid is obtained by modifying polylactic acid with butyl acrylate, trimethylolpropane triacrylate, and tert-butyl peroxybenzoate;

[0090] The modified palygorskite is obtained by purifying and modifying palygorskite.

[0091] The steps of palygorskite purification are as follows: Weigh the palygorskite powder with a particle size of 50-100 μm, add it to an ethanol solution with a mass concentration of 50-60%, ultrasonicate for 1-2 hours, filter the solid matter, and dry , to obtain palygorskite purified product;

[0092] Among them, the solid-to-liquid ratio of palygorskite powder to ethanol solution is 1:30-50.

[0093] The modified steps of palygors...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com