Steel top piston for large-cylinder-diameter gas engine

A gas engine, large cylinder diameter technology, applied in the direction of engine components, machines/engines, pistons, etc., can solve the problems of difficult welding process of piston head oil passage inner cavity, aluminum piston is difficult to withstand explosion pressure impact, high mold cost and other problems, Achieve the effects of increasing volume and cooling capacity, reducing combustion vortex loss, and fast flame propagation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with embodiment, the present invention is further described, but does not constitute any restriction to the present invention, anyone makes the limited number of amendments in the scope of claims of the present invention, still within the scope of claims of the present invention.

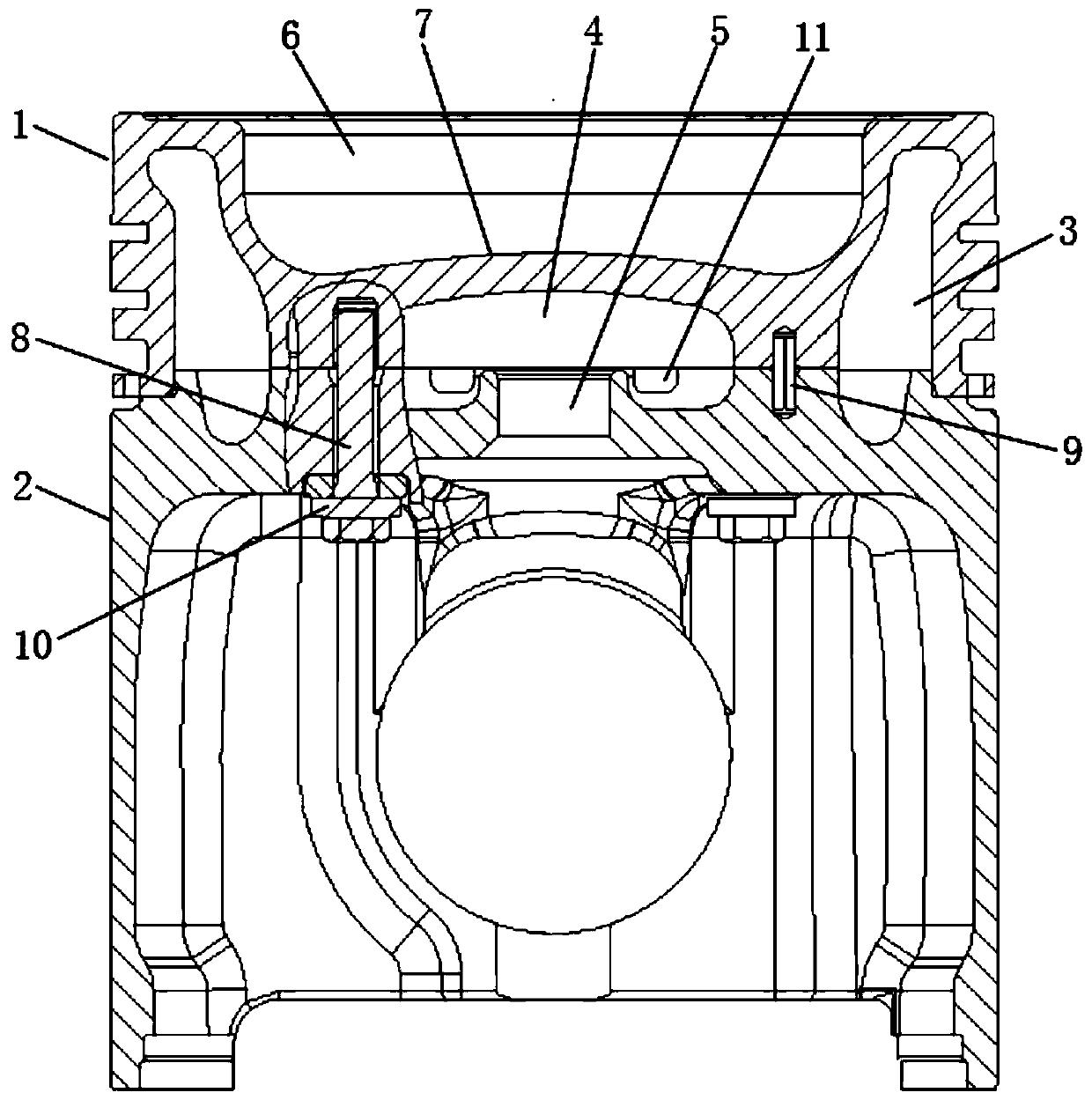

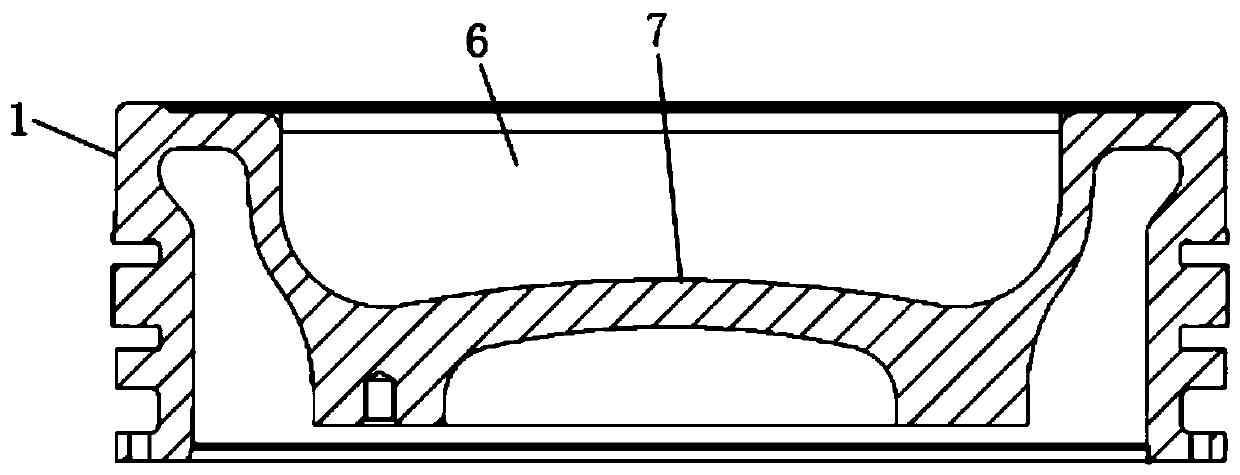

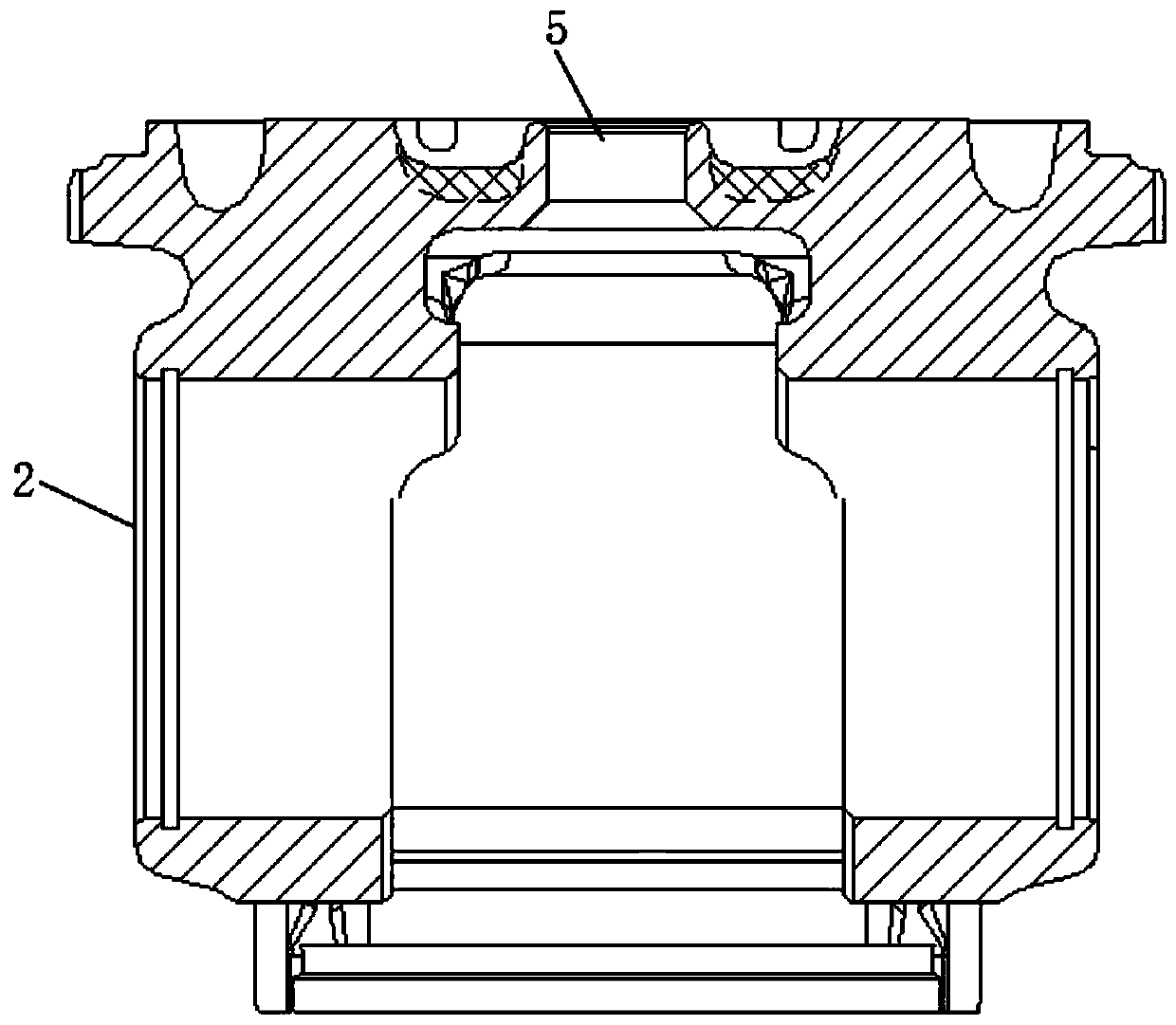

[0031] refer to Figure 1-Figure 4 , a steel top piston for a large-bore gas engine of the present invention includes a steel piston head 1 and a ductile iron piston skirt 2. The steel piston head 1 effectively ensures its strength and avoids the problem of cracking and melting of the top of the aluminum piston. The piston skirt 2 made of iron solves the problems of high cost, difficult welding process and heavy overall weight caused by the all-steel piston. The piston with steel top and iron skirt effectively improves the reliability of the piston.

[0032] The piston skirt 2 is plugged into the piston head 1 and connected through a connection assembly. That is, the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com