Hypertension, hyperglycemia and hyperlipidemia reduction fagopyrum tararicum coarse cereal powder

A technology of miscellaneous grain powder and three-high reduction, which is applied to the functions of food ingredients, milk preparations, food ingredients containing oligosaccharides, etc., and can solve the problems of low content of active components, low stability of active components, degradation of active substances, etc. problem, to achieve the effect of rich nutrition, improving immunity and lowering blood sugar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

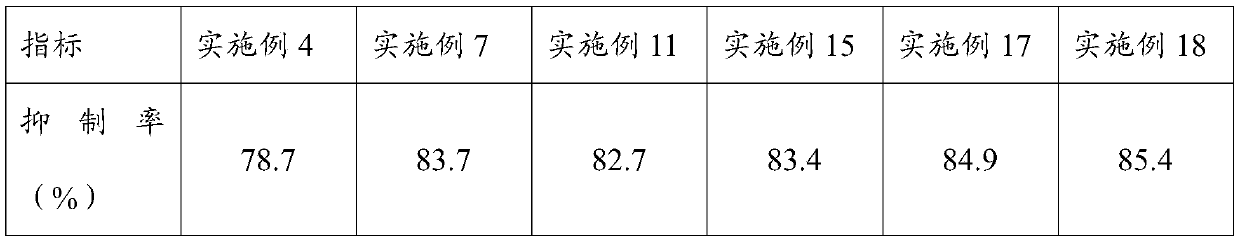

Examples

preparation example Construction

[0035] A preparation process of Jiangsangao tartary buckwheat miscellaneous grain powder, comprising the steps of:

[0036] Tartary buckwheat powder, Jerusalem artichoke powder and skimmed milk powder are mixed according to mass ratio to form the first component, konjac fine powder and carrier are mixed according to mass ratio to form the second component, citric acid and sweetener are mixed according to mass ratio After proportioning and mixing, the third composition is formed;

[0037] The first component is dissolved in water to form the first component liquid, the second component is dissolved in water to form the second component liquid, the first component liquid and the second component liquid are mixed to form a mixed liquid, and the mixed The liquid is spray-dried to obtain mixed powder, and the mixed powder is uniformly mixed with the first component to obtain Jiangsangao tartary buckwheat miscellaneous grain powder.

[0038] A preparation process of Jiangsangao tar...

Embodiment 1

[0042] The preparation process of tartary buckwheat powder is as follows: tartary buckwheat seeds are germinated with water, soaking time is 18 hours, soaking temperature is 15°C, after vacuum freezing-hot air drying, the powder is ground to obtain tartary buckwheat powder, hot air drying is performed first, and then vacuum freezing Drying treatment: hot air temperature 55℃, hot air time 2h; freezing temperature -30℃~-20℃, drying time 3h.

Embodiment 2

[0044] The preparation process of tartary buckwheat powder is as follows: tartary buckwheat seeds are germinated with water, soaked for 24 hours, and soaked at a temperature of 10°C. After combined vacuum freezing and hot air drying, the tartary buckwheat powder is ground to obtain tartary buckwheat powder. First, hot air drying is carried out, and then vacuum freezing Drying treatment: hot air temperature 50℃, hot air time 1h; freezing temperature -30℃~-20℃, drying time 5h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com