Preparation method of nitrogen-doped water electrolysis oxygen production heterogeneous catalyst

A technology of electrolysis of water and nitrogen doping, applied in chemical instruments and methods, physical/chemical process catalysts, electrolysis processes, etc., can solve the waste of materials and energy, reduce catalyst activity and catalytic efficiency, and limit the full exposure of catalyst active sites And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

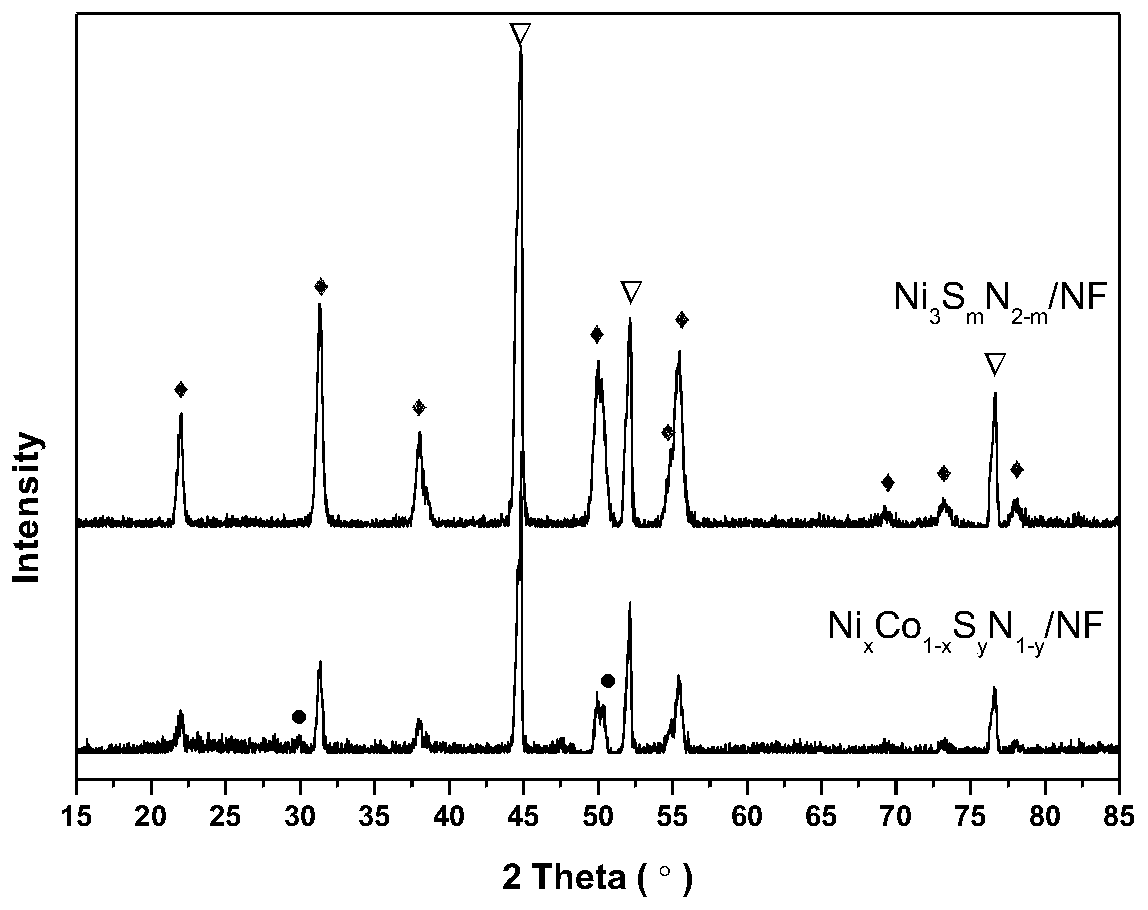

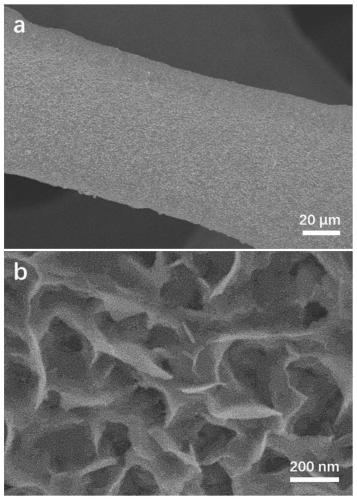

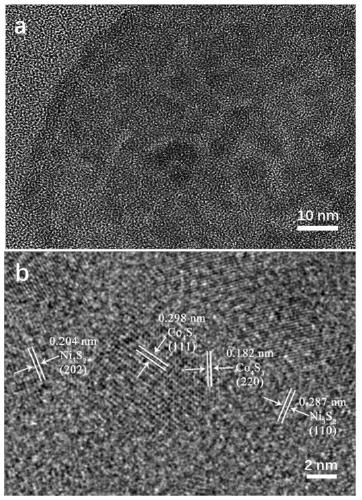

Embodiment 1

[0020] Solvothermal one-pot reaction: 30mg of cobalt acetate, 150mg of thiourea, and 10mg of ammonium fluoride were dissolved in a mixed solvent composed of 7mL of deionized water and 14mL of ethylene glycol. Put washed 1×4cm 2 Foam nickel, then put the high-temperature and high-pressure reactor into a 120°C constant temperature oven, keep it warm for 4 hours, then raise the temperature to 160°C, keep it warm for 3 hours, cool naturally, take it out, wash it, and dry it to get the foamed nickel-based Co 4 S 3 / Ni 3 S 2 nanosheet composites.

[0021] High-temperature nitriding reaction: using ammonia gas as the nitrogen source, before the nitriding reaction starts, the foamed nickel-based Co 4 S 3 / Ni 3 S 2 The nanosheet composite material is placed in a quartz boat, and then placed in a quartz tube in a tubular resistance furnace. The quartz tube is closed and fully evacuated, and then filled with ammonia gas until the pressure is 0; the temperature is raised to 10°C / mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com