Aerogel heat insulation glass and preparation method thereof

A thermal insulation and aerogel technology, applied in the field of aerogel thermal insulation glass and its preparation, can solve the problems of light transmittance, unsatisfactory mechanical strength of thermal insulation performance, etc. High temperature resistance performance, the effect of improving thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

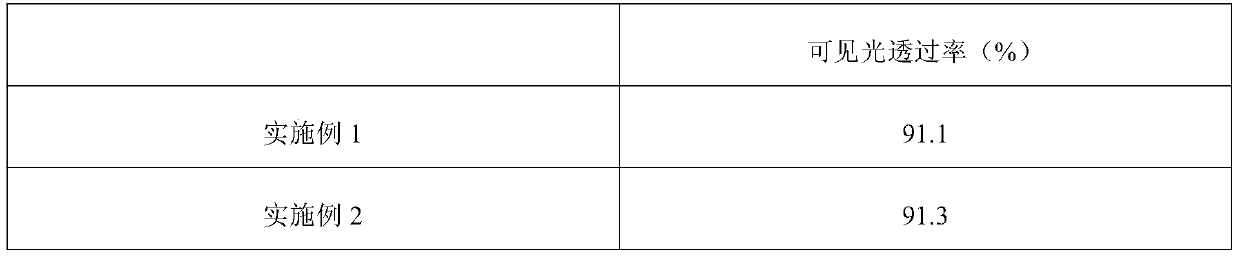

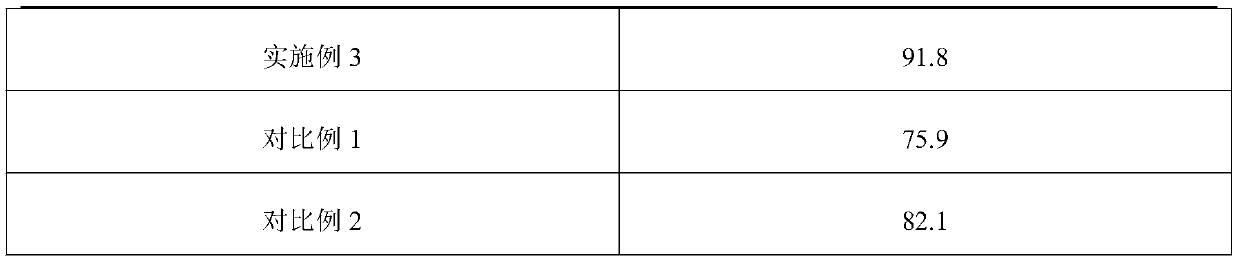

Examples

Embodiment 1

[0031] A preparation method of airgel thermal insulation glass, in parts by weight, the specific steps are as follows:

[0032] (1) At 20°C, first mix and stir 1 part of ethyl orthosilicate, 0.4 parts of vinylmethyldiethoxysilane and 3 parts of absolute ethanol, and slowly add 0.4 parts of 0.03mol dropwise while stirring / L hydrochloric acid solution, after the dropwise addition, add 0.2 part of trimethyl borate, continue to stir, sol;

[0033] (2) Then add 2 parts of aluminum nitrate and 0.6 part of titanium nitrate into 6 parts of deionized water, stir until completely dissolved, add 3.5 parts of citric acid monohydrate, and stir evenly to obtain a premixed solution;

[0034] (3) Then add the sol body obtained in step (1) to 0.25 parts of absolute ethanol, ultrasonically oscillate for the first time, then add the premixed solution obtained in step (2), and evenly and slowly add 1mol / L ammonia water dropwise to adjust pH=7, The second ultrasonic oscillation, post-processing,...

Embodiment 2

[0048] A preparation method of airgel thermal insulation glass, in parts by weight, the specific steps are as follows:

[0049] (1) At 30°C, first mix and stir 1 part of ethyl orthosilicate, 0.3 parts of vinylmethyldiethoxysilane and 5 parts of absolute ethanol, and slowly add 0.3 parts of 0.05mol dropwise while stirring / L hydrochloric acid solution, after the dropwise addition, add 0.1 part of trimethyl borate, continue to stir, the sol body;

[0050] (2) Then add 3 parts of aluminum nitrate and 0.4 part of titanium nitrate into 8 parts of deionized water, stir until completely dissolved, add 3 parts of citric acid monohydrate, and stir evenly to obtain a premixed solution;

[0051] (3) Next, add the sol obtained in step (1) to 0.35 parts of absolute ethanol, ultrasonically oscillate for the first time, then add the premixed solution obtained in step (2), and evenly and slowly add 0.8mol / L ammonia water dropwise to adjust pH=7 , the second ultrasonic oscillation, post-proce...

Embodiment 3

[0065] A preparation method of airgel thermal insulation glass, in parts by weight, the specific steps are as follows:

[0066] (1) At 25°C, first mix and stir 1 part of ethyl orthosilicate, 0.35 parts of vinylmethyldiethoxysilane and 4 parts of absolute ethanol, and slowly add 0.35 parts of 0.04mol dropwise while stirring / L hydrochloric acid solution, after the dropwise addition, add 0.15 parts of trimethyl borate, continue to stir, the sol body;

[0067] (2) Then add 2.5 parts of aluminum nitrate and 0.5 part of titanium nitrate into 7 parts of deionized water, stir until completely dissolved, add 3.2 parts of citric acid monohydrate, and stir evenly to obtain a premix;

[0068] (3) Next, add the sol obtained in step (1) to 0.3 parts of absolute ethanol, ultrasonically oscillate for the first time, then add the premixed solution obtained in step (2), and evenly and slowly add 0.9 mol / L ammonia water dropwise to adjust pH=7 , the second ultrasonic oscillation, post-processi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com