Solid propellant and horizontal additive manufacturing method thereof

A solid propellant and propellant technology, applied in the direction of additive processing, offensive equipment, compressed gas generation, etc., can solve the problems of plastic deformation and curing time, achieve the effect of reducing curing temperature, shortening curing time, and speeding up prototype manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The solid propellant of the present embodiment includes: metal additives, binders, oxidizing agents, plasticizers and curing agents, and also includes: neutral bonding agents, burning rate catalysts and curing catalysts. Wherein said curing agent is isocyanate. The curing agent includes: at least one of toluene diisocyanate and isophorone diisocyanate.

[0038] The solid propellant of this embodiment is a ternary hydroxybutyl propellant, and the mass percentages of each component in the ternary hydroxybutyl propellant are: ammonium perchlorate 69.5%, aluminum powder 18.5%, hydroxyl-terminated polybutylene 8.4% of diene, 3.5% of diisooctyl sebacate, 0.058% of toluene diisocyanate, 0.02% of isophthaloyl, 0.020% of iron oxide, and 0.002% of triphenylbismuth.

[0039] Wherein, ammonium perchlorate is used as an oxidizing agent, and its percentage that accounts for the mass of raw material is between 47%~70%;

[0040] Aluminum powder is used as a metal additive, and its ma...

Embodiment 2

[0050] The solid propellant of this embodiment is a quaternary butylated hydroxy propellant, and the mass percentages of the components of the quaternary butylated hydroxy propellant are: ammonium perchlorate 47%, aluminum powder 18%, octogold 25%, hydroxyl-terminated polybutadiene 7%, diisooctyl sebacate 2.83%, toluene diisocyanate 0.048%, isophthaloyl 0.1%, iron oxide 0.02%, triphenylbismuth 0.002%.

[0051] In the above-mentioned quaternary hydroxybutyl propellant, the particle size gradation of ammonium perchlorate is as follows: the particle size is 250 μm, the content is 30%, the particle size is 120 μm, the content is 20%, the particle size is 20 μm, the content is 30%, The content of the particle size is 1 μm is 20%; the particle size gradation of the aluminum powder is: the content of the particle size of 165 μm is 50%, the content of the particle size of 30 μm is 20%, and the content of the particle size of 20 μm is 30%.

Embodiment 3

[0053] This embodiment provides a horizontal additive manufacturing method for a solid propellant, comprising the following steps:

[0054] Step 1: premixing the raw materials of the solid propellant into at least two groups, so that the metal additive and the oxidant are processed separately;

[0055] In the group where the metal additive is located, the adhesive is premixed with the metal additive to form a main ingredient;

[0056] In the group where the oxidizing agent is located, the oxidizing agent is pre-mixed with a curing agent to form a slurry;

[0057] The main material and the slurry are mixed into a propellant material in a mixer.

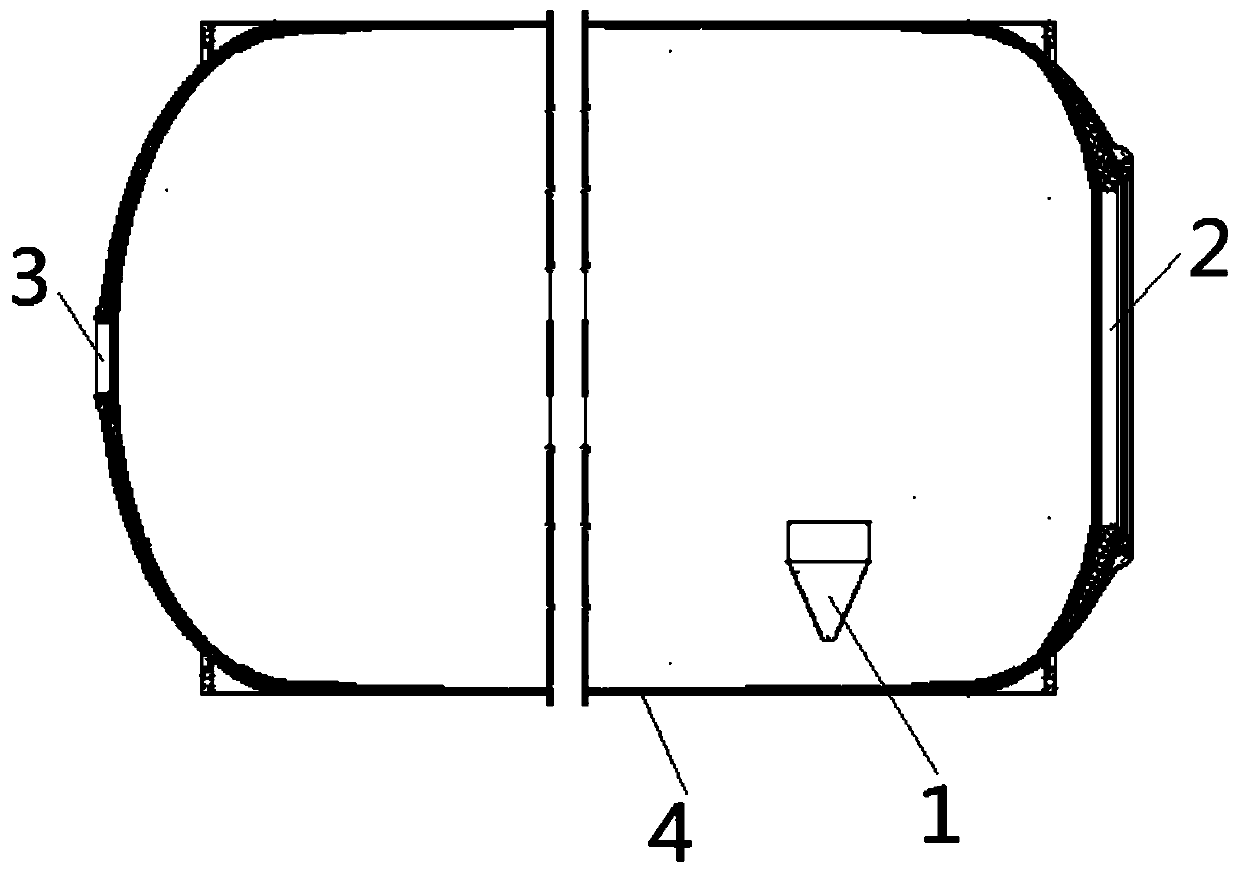

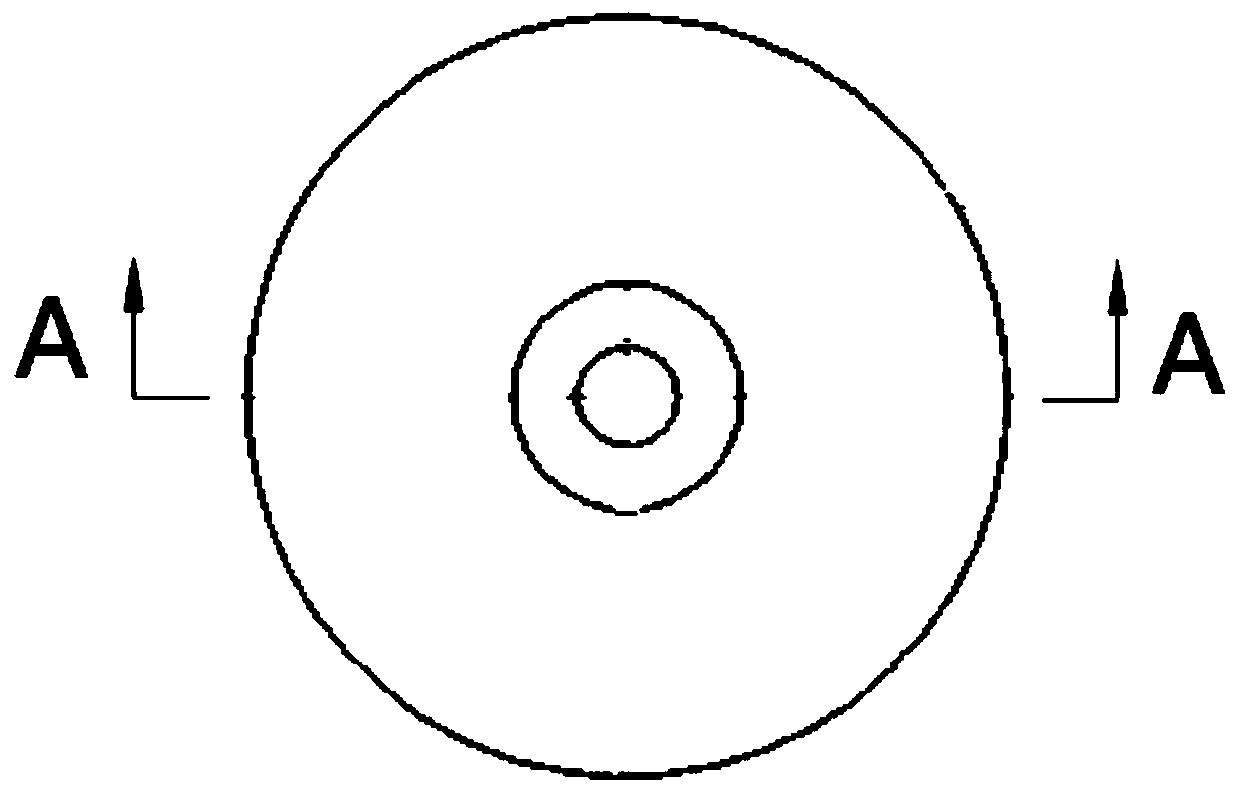

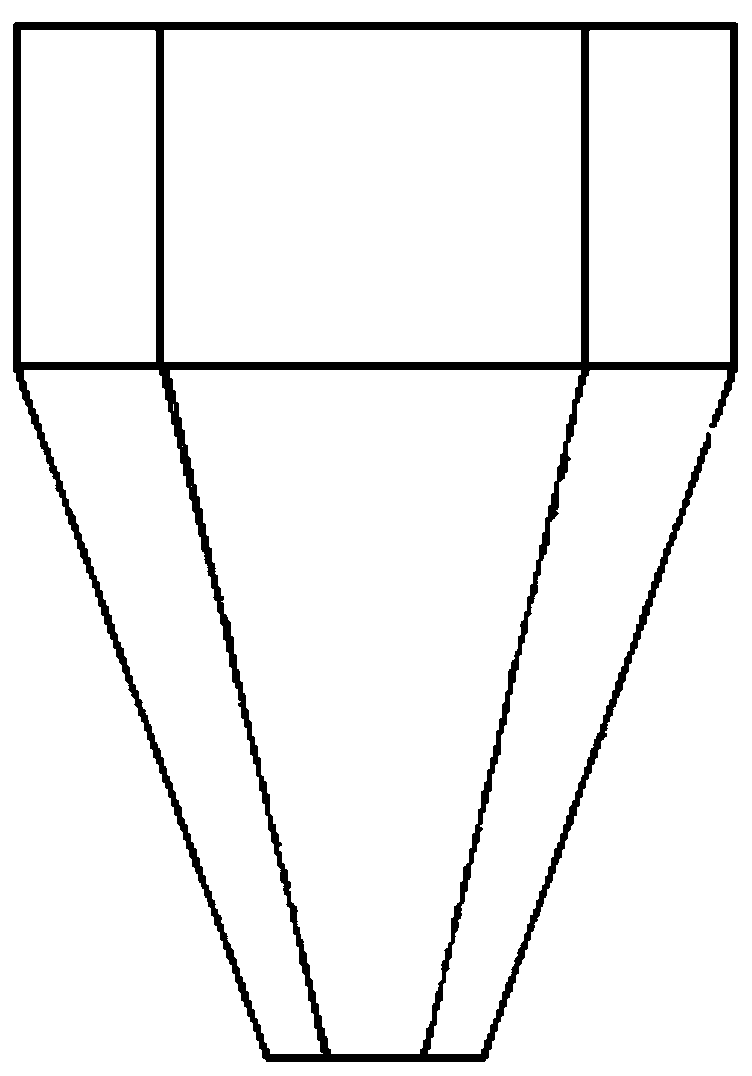

[0058] Step 2: Transport the propellant raw material to the channel of the propellant printing nozzle 1; and adjust the output flow rate of the propellant printing nozzle 1 as required; the propellant printing nozzle 1 has a plurality of concentric channels with different diameters, which can According to the required printing size a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com